| –

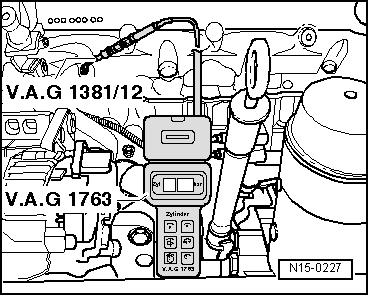

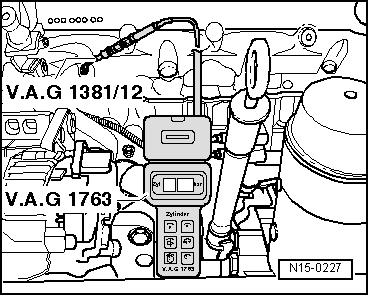

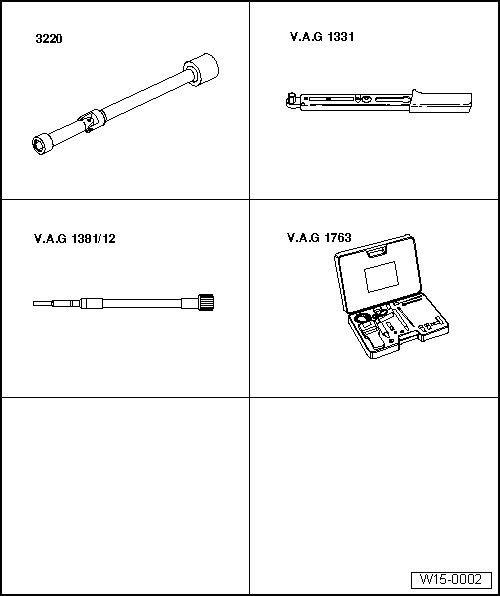

| Screw in adapter -V.A.G 1381/12- in place of glow plugs or ceramic glow plugs. |

| –

| Check compression using compression tester -V.A.G 1763-. |

Note | Using the compression tester ⇒ Operating instructions. |

| –

| Operate starter until tester shows no further pressure increase. |

| New: 25 … 31 bar, wear limit: 19 bar |

| Maximum permissible difference between all cylinders: 5 bar |

Note | If ceramic glow plugs are fitted, always observe notes on removing and installing ceramic glow plugs → Chapter. |

| –

| Remove glow plugs or ceramic glow plugs using jointed extension and socket -3220-. |

| –

| Read fault memory of engine control unit → Chapter. |

Note | Disconnecting the central connector for unit injectors causes faults to be stored. Therefore, read fault memory and clear if necessary. |

|

|

|

Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note Note

Note