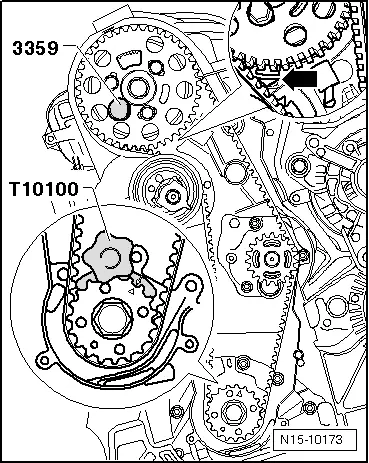

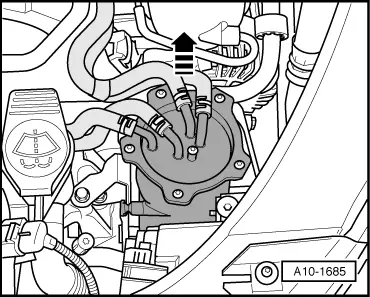

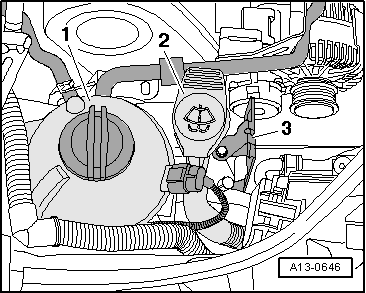

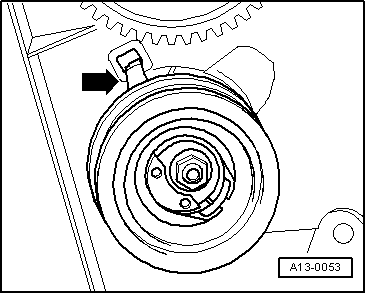

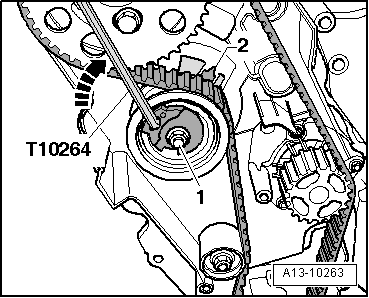

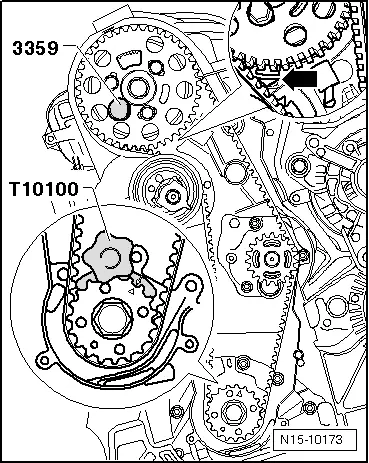

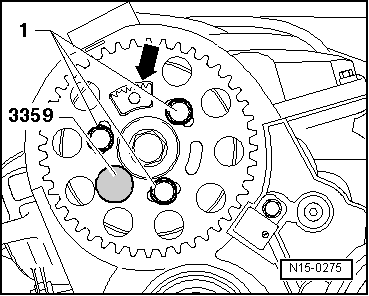

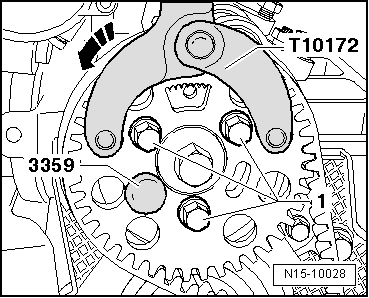

| Turn crankshaft until marking on crankshaft pulley and tooth segment of camshaft pulley is on top. The marking on the rear toothed belt guard must align with the marking on the camshaft sender wheel -arrow-. |

| –

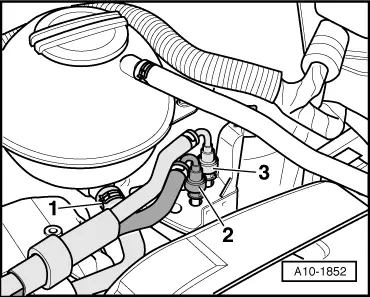

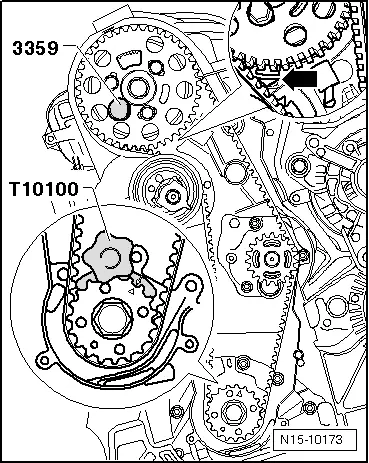

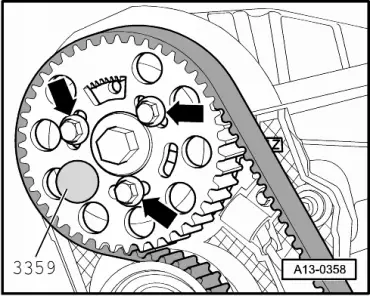

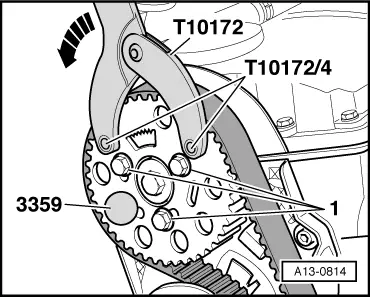

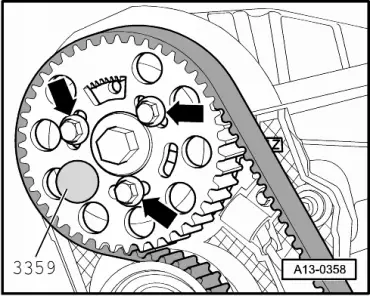

| Lock hub using locking pin -3359-. To do this, slide locking pin through the free elongated hole on left into hole in cylinder head. |

| –

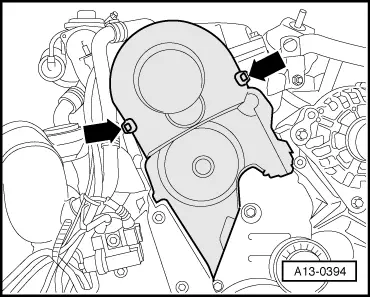

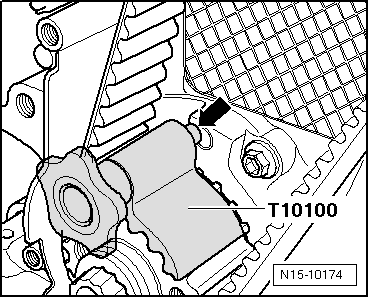

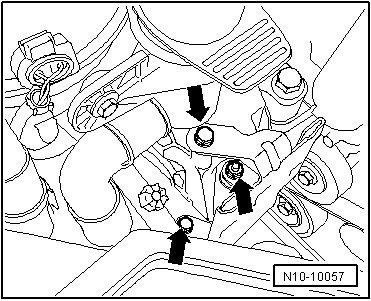

| Lock crankshaft toothed belt pulley with crankshaft stop -T10100-. To do this, push crankshaft stop into teeth of belt pulley from face side. |

Note | The marks on the crankshaft toothed belt pulley and the crankshaft stop must align. When doing this, the pin of the crankshaft stop must engage in the drilling of sealing flange. |

| –

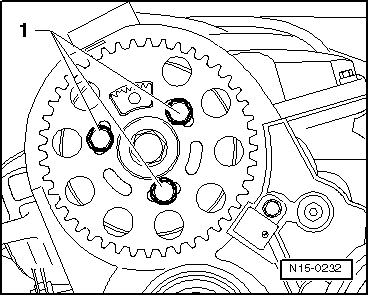

| Mark direction of rotation of toothed belt. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING