Golf Mk5

| Changing and adjusting vacuum unit on turbocharger - only vehicles with engine code: BLS from model year 2008 |

| Special tools and workshop equipment required |

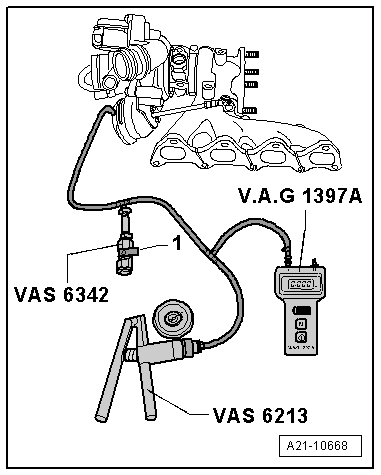

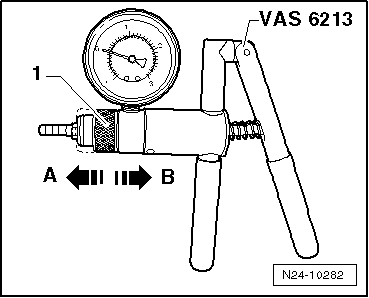

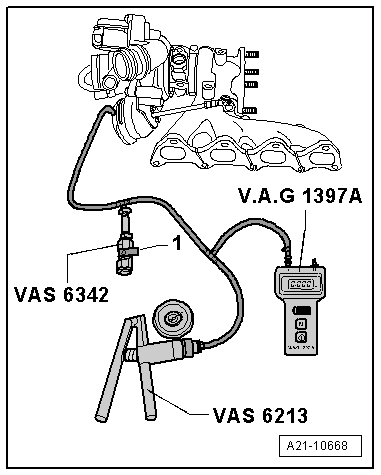

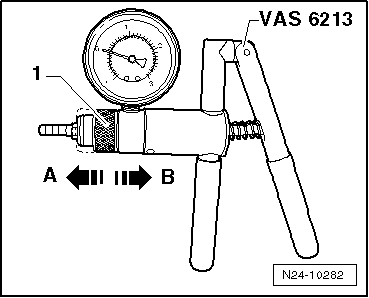

| t | Hand vacuum pump -VAS 6213- |

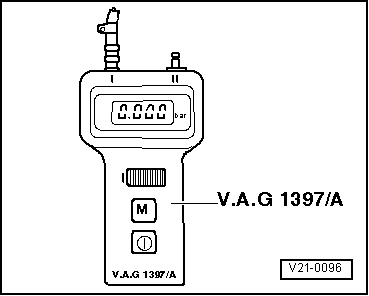

| t | Turbocharger tester -V.A.G 1397A- |

| t | Pressure regulating valve -VAS 6342- |

| t | Ring spanner -T10423- |

| t | Allen key, long reach -T10454- |

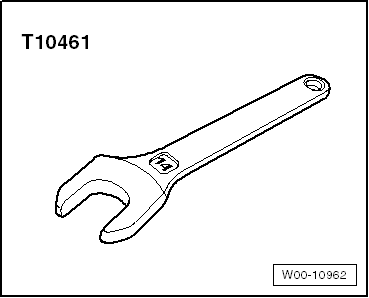

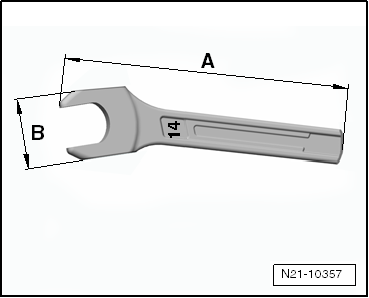

| t | 14 mm open-end spanner -T10461- |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

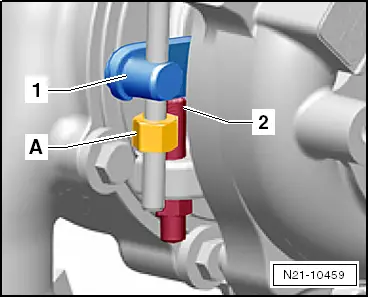

Caution

Caution