Note | Do not cant ceramic glow plugs when removing and installing. Remove any components hindering assembly. |

| –

| Pull connectors off ceramic glow plugs. |

| –

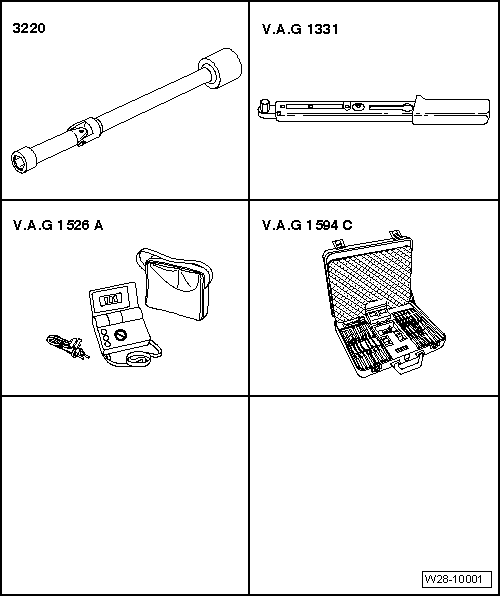

| Remove ceramic glow plugs using U/J extension and socket, 10 mm -3220-. |

| Installation is carried out in the reverse order. When installing, note the following: |

| –

| Before installing the drilling in cylinder head and the threads must completely cleaned of all deposits. |

Note | Do not oil or grease thread of cylinder head bore or of ceramic glow plugs. |

| –

| Screw ceramic glow plugs into cylinder head by hand using U/J extension and socket, 10 mm -3220-. |

| –

| Then tighten the ceramic glow plugs. Specified torque: 15 Nm. |

WARNING | t

| After installing and before the engine is started, perform a resistance test on all ceramic glow plugs when engine is cold. |

| t

| If the defective ceramic glow plug is broken, remove all fragments from the engine, otherwise these can cause damage to the engine. |

|

| t

| Specification: max. 1 Ω |

| –

| If the specification is exceeded, renew the defective ceramic glow plug. |

|

|

|

Note

Note Note

Note

WARNING

WARNING