| –

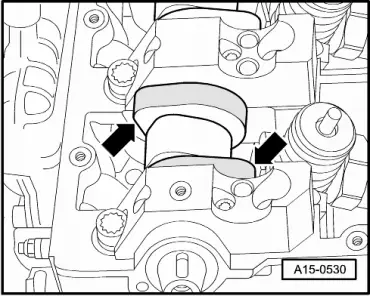

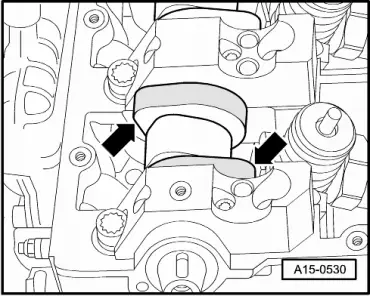

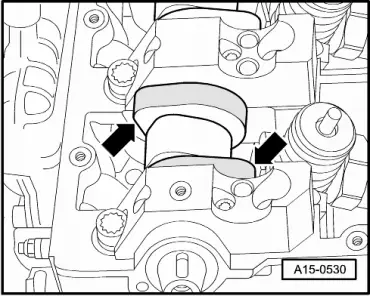

| After tightening cylinder head, turn camshaft so that cams for No. 1 cylinder point equally upwards. Turn crankshaft, in engine direction of rotation, to TDC marking before fitting toothed belt → Chapter. |

| Observe applicable safety precautions during road test → Chapter. |

| –

| Carry out road test and then read fault memory → Chapter. |

|

|

|

Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note