| t

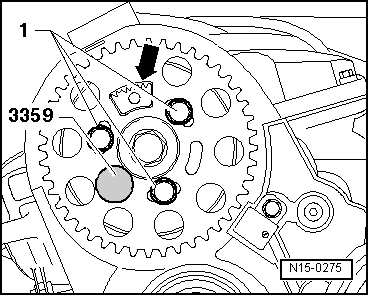

| When camshaft is installed, No. 1 cylinder cams must point upwards. |

| t

| Do not interchange used bearing shells (mark). |

| t

| When installing the camshaft, ensure proper seating of retaining lugs in bearing caps and cylinder head. |

| t

| Before installing bearing caps, ensure that cylinder head bolt washers are inserted in the cylinder head. |

| –

| Oil bearing shell running surfaces. |

| –

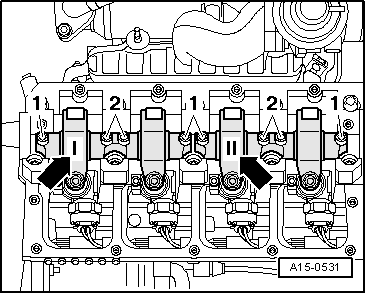

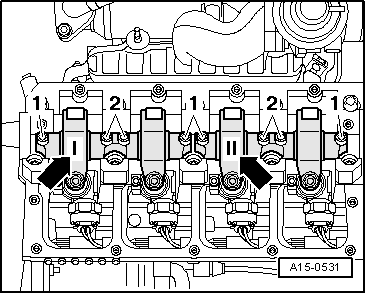

| Install bearing caps 2 and 4 using new bolts. |

| –

| Tighten bearing caps 2 and 4 diagonally and alternately to 8 Nm +1/4 turn (90°). |

| –

| Install bearing caps 5, 1 and 3 using new bolts. |

Note | t

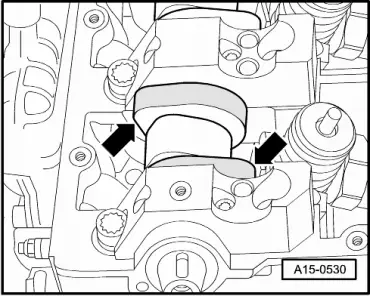

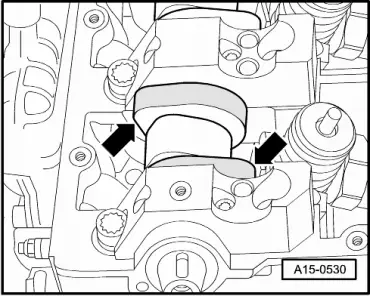

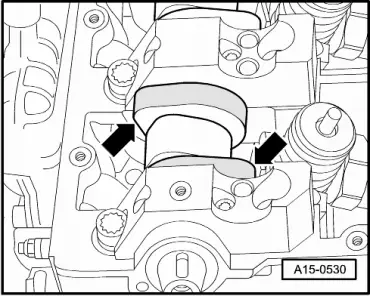

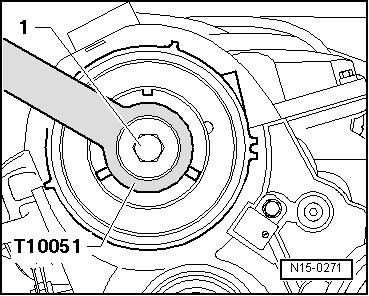

| Seal parting surfaces of bearing caps 1 and 5 with sealant -AMV 174 004 01- → Fig.. |

| t

| Bearing cap 5 must align flush with outer edge of cylinder head, because otherwise leaks can develop at tandem pump. |

| –

| Tighten bearing caps 5, 1 and 3 likewise to 8 Nm +1/4 turn (90°). |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note Note

Note