| –

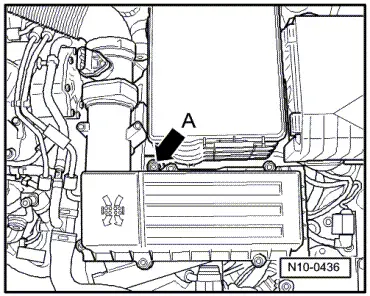

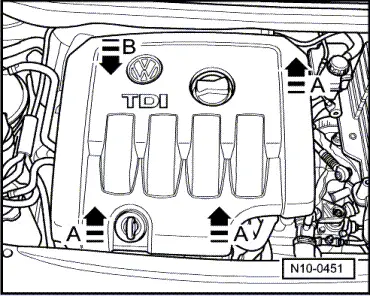

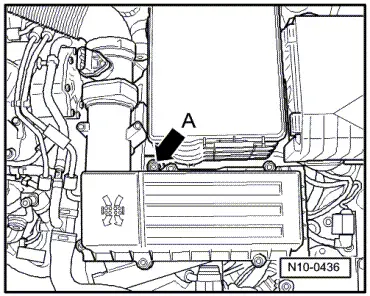

| Remove air filter housing with air mass meter and connecting pipe. |

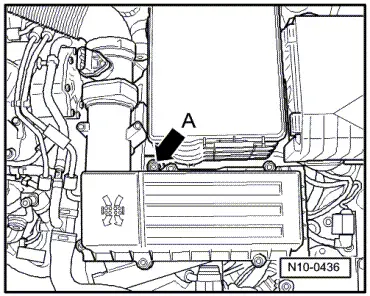

| Remove bolt -arrow A- and pull air filter housing upwards out of mounting. |

| –

| Remove battery and battery tray. |

WARNING | t

| The fuel and the fuel lines in the fuel system can become very hot (danger of scalding)! |

| t

| The fuel system is also under pressure! Before opening the system, place cloths around the connections. Then carefully loosen connection to release the pressure! |

| t

| Wear eye and hand protection when performing any type of repair work on the fuel system! |

|

| –

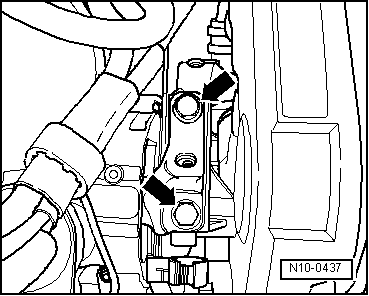

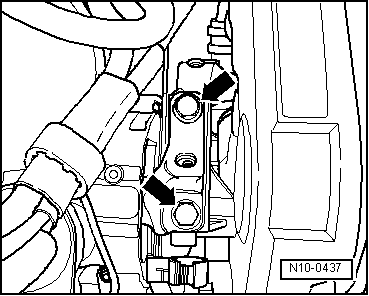

| Disconnect fuel supply and return lines as well as coolant line on cylinder head. |

| –

| Pull fuel filter module upwards out of bracket and lay it with hoses to side. |

| Vehicles with air conditioner |

Note | To prevent damage to condenser and also to refrigerant lines/hoses, ensure that the lines and hoses are not stretched, kinked or bent. |

| To facilitate removing and installing engine without opening refrigerant circuit: |

| –

| Secure air conditioner compressor to lock carrier so that refrigerant lines are relieved. |

| Continuation for all vehicles |

| –

| Remove exhaust pipe and coolant hoses from supplementary heater. |

| –

| Remove connecting pipes between charge air cooler and engine. |

| –

| Pull retainer for wiring harness of oil level and oil temperature sender -G266- off subframe. |

| –

| Remove left wheel housing liner. |

| –

| Disconnect front exhaust pipe from turbocharger, loosen double clamp and slide exhaust pipe back → Chapter. |

| –

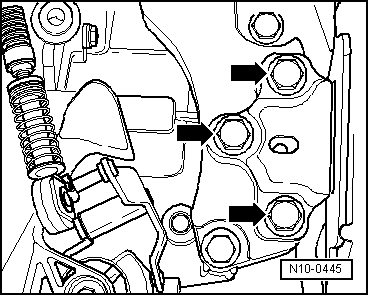

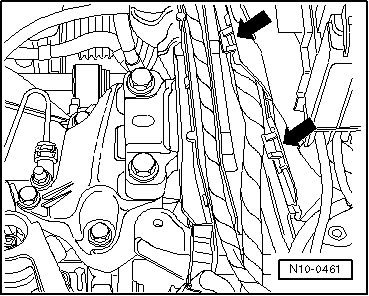

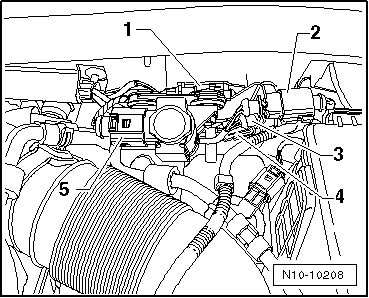

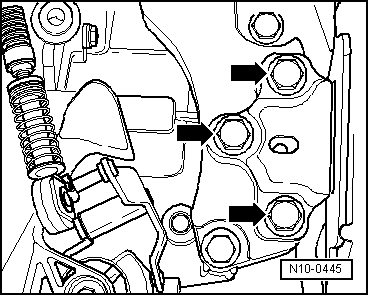

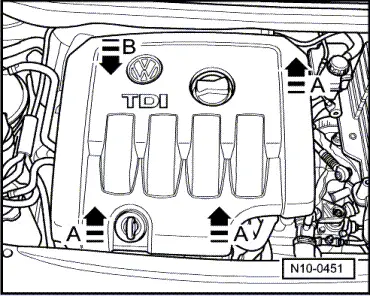

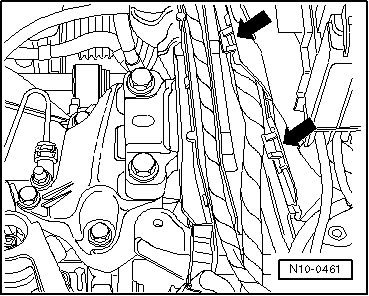

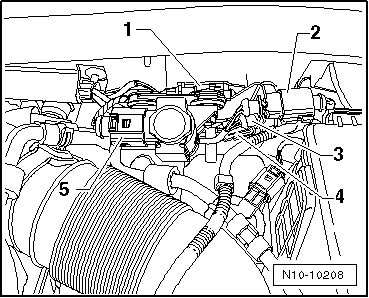

| Pull engine wiring harness connector off control unit: |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note