| –

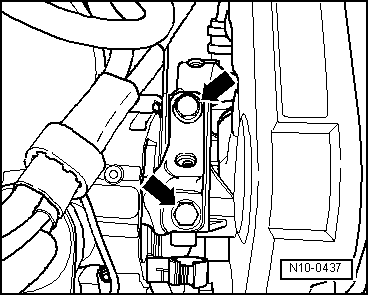

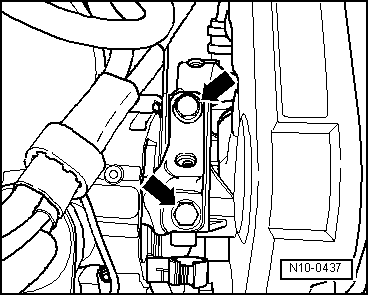

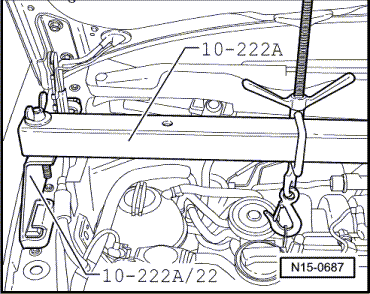

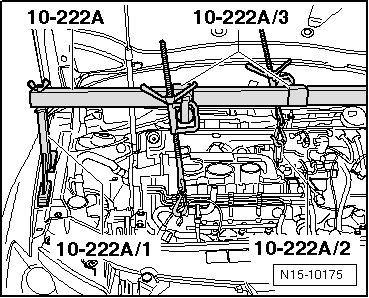

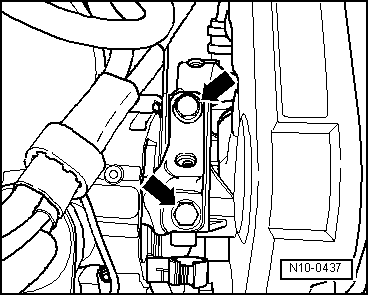

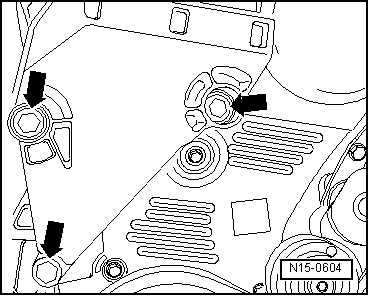

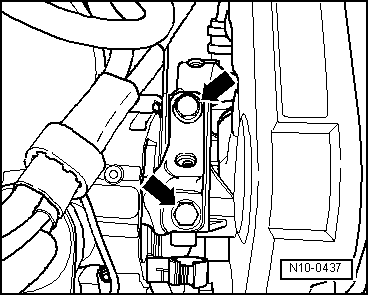

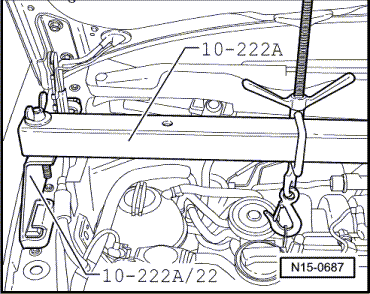

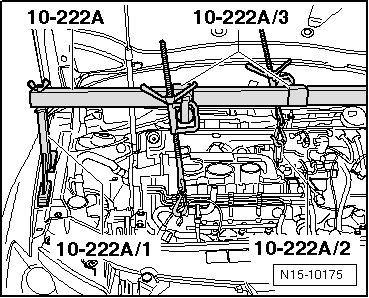

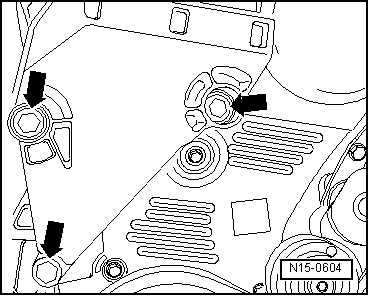

| Bolt engine assembly mounting to engine support -arrows- by bringing contact surfaces together using support bracket -10-222A-. Specified torque: 60 Nm + 90° (1/4 turn) further |

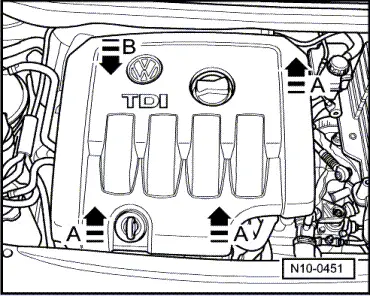

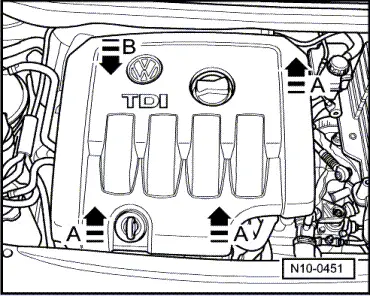

| Further assembly is basically the reverse of the dismantling sequence. In the process, note the following: |

| t

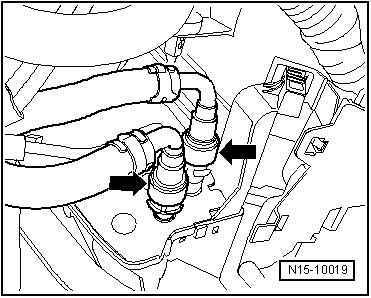

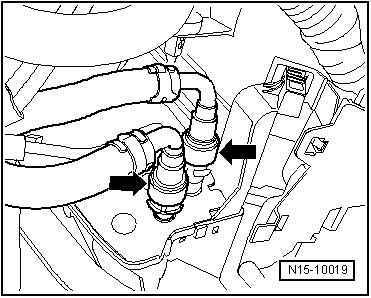

| Ensure that fuel hose connections are tight. |

| t

| Do not interchange supply and return lines (return line blue or with blue markings, supply line black). |

| t

| When installing charge air pipes, ensure that locking lugs engage correctly. |

| –

| Install wheel housing liner. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note