Golf Mk5

|

|

|

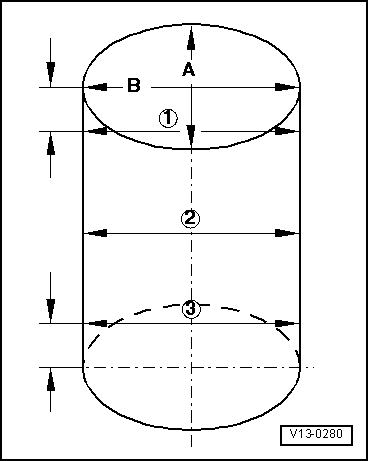

| Piston ring dimensions in mm | New | Wear limit |

| 1. compression ring | 0.20...0.40 | 1.0 |

| 2. compression ring | 0.20...0.40 | 1.0 |

| Oil scraper ring | 0.25...0.50 | 1.0 |

|

|

| Piston ring dimensions in mm | New | Wear limit |

| 1. compression ring | 0.06...0.09 | 0.25 |

| 2. compression ring | 0.05...0.08 | 0.25 |

| Oil scraper ring | 0.03...0.06 | 0.15 |

|

|

Note

Note