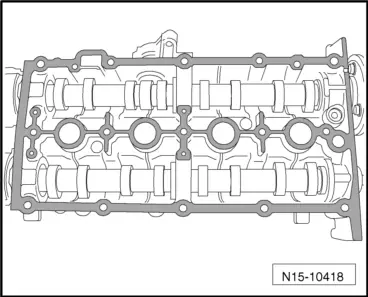

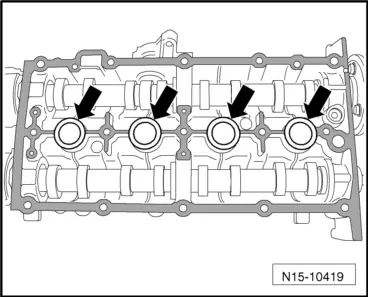

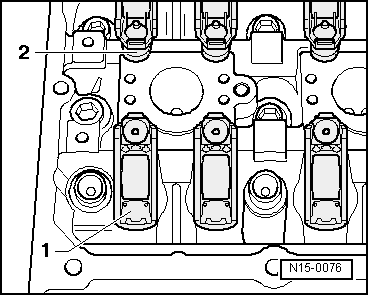

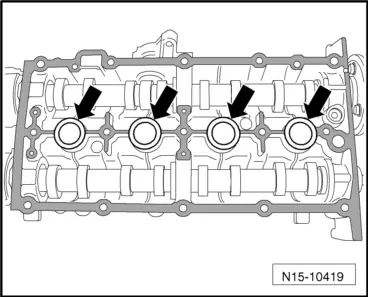

Caution | The studs (M6x80) must be screwed into cylinder head before installing camshaft housing. |

| The camshaft housing is guided by the studs, so that the roller rocker fingers do not slip off the supporting elements. |

|

| l

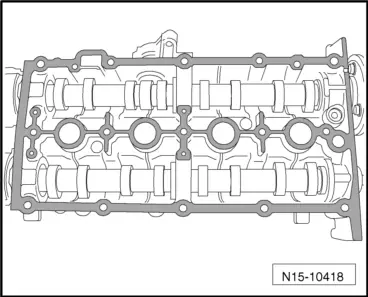

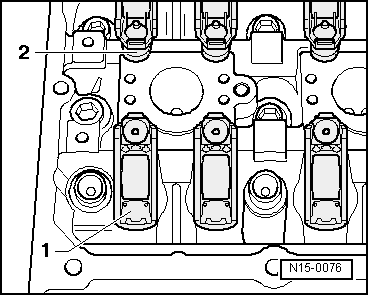

| The pistons must not be positioned at TDC. |

| –

| Remove sealant residues from cylinder head and camshaft housing with a rotating brush, e.g. a hand drill with a plastic brush (wear eye protection). |

| –

| Clean sealing surfaces carefully. They must be free of oil and grease. |

| –

| Also prevent dirt and residual sealant from entering cylinder head. |

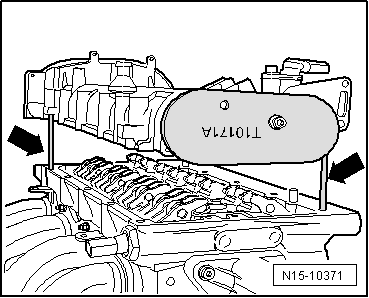

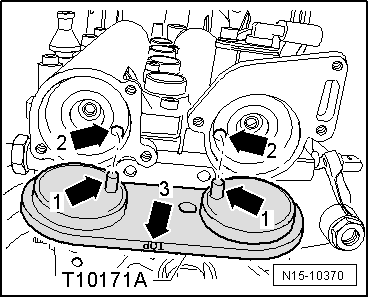

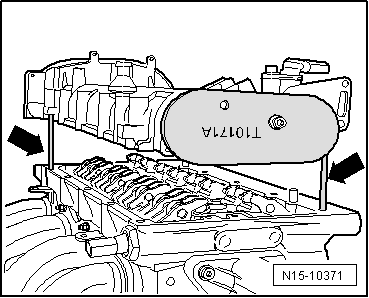

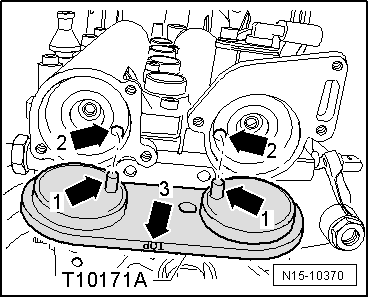

Caution | Before using camshaft clamp -T10171 A- you must check that the pins on the tool project by at least 7 mm. |

| If this is not the case, the camshaft clamp is defective and must be renewed. |

| The camshaft clamp must not be positioned using any kind of hammer. |

|

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

Note

Note

Note

Note Note

Note