| Installation is carried out in the reverse order. When installing, note the following: |

Caution | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

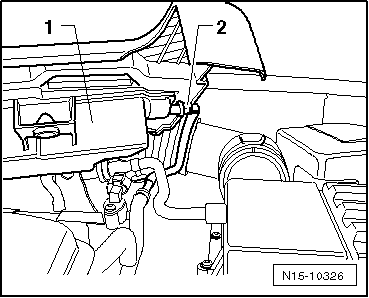

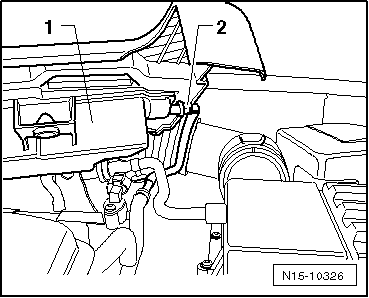

| Route all the various lines (e.g. for fuel, hydraulics, activated charcoal filter system, coolant and refrigerant, brake fluid and vacuum) and electrical wiring in their original positions. |

| t

| To avoid damage to lines, ensure sufficient clearance to all moving or hot components. |

|

| –

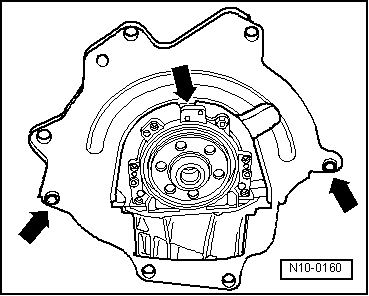

| Check clutch release bearing for wear and renew if necessary. |

| –

| Lightly grease clutch release bearing, release bearing guide sleeve and splines on input shaft with G 000 100. |

| –

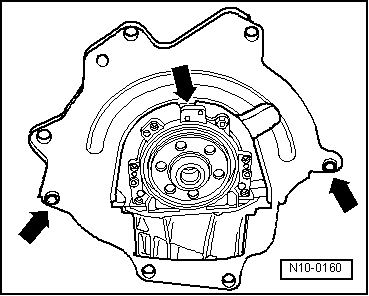

| Check whether dowel sleeves for centring engine/gearbox have been fitted in cylinder block, insert if necessary. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note