| –

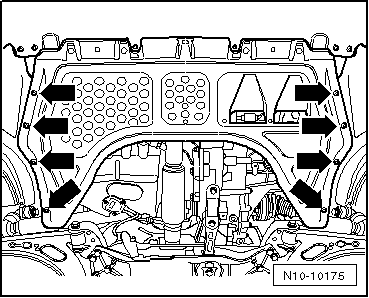

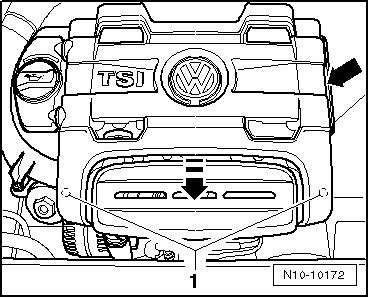

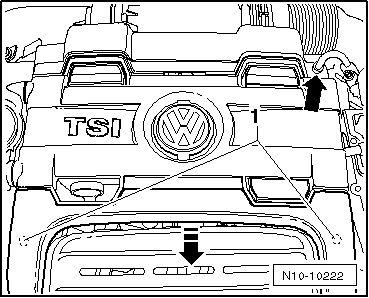

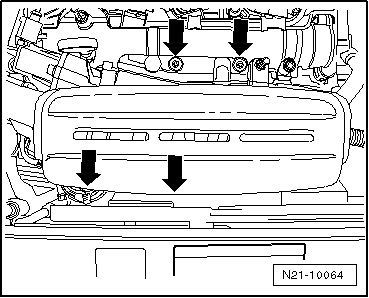

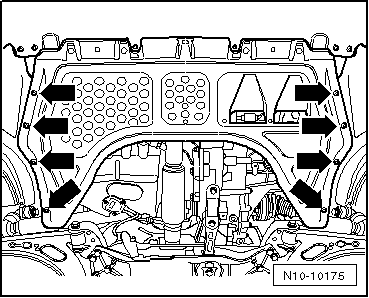

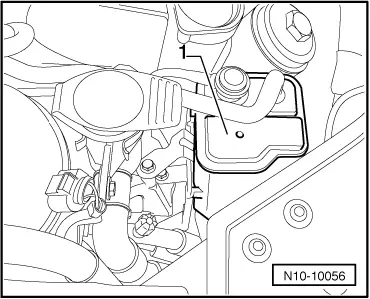

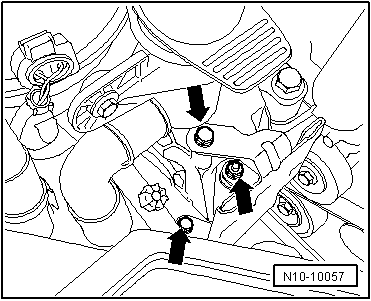

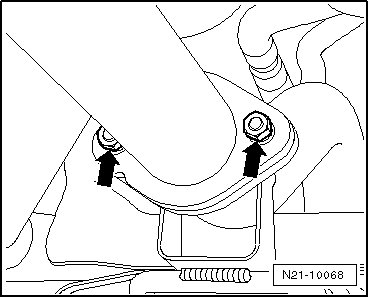

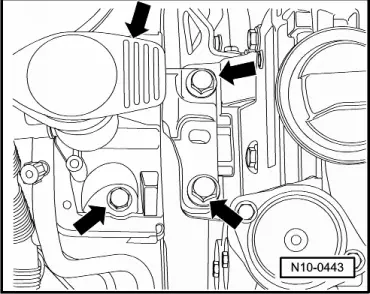

| Remove securing bolts -arrows- of engine splash protection. |

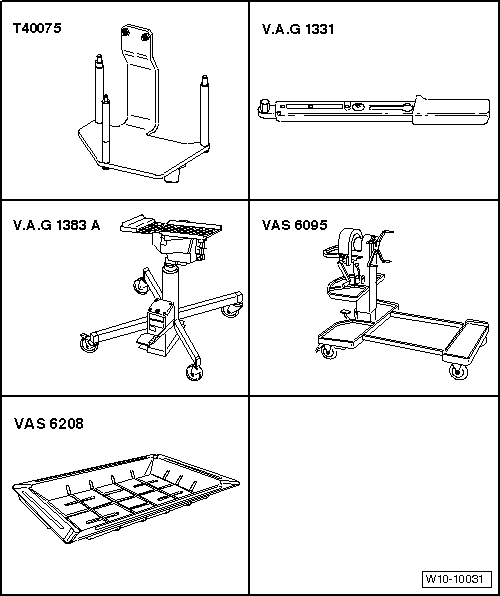

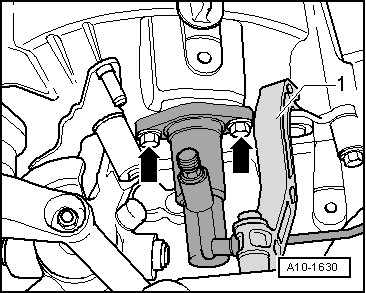

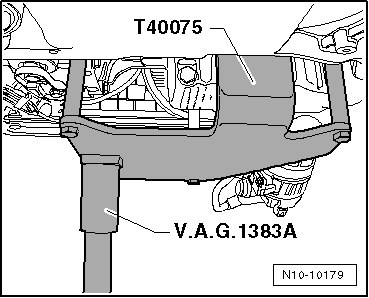

| The engine is removed downwards together with the gearbox. |

| –

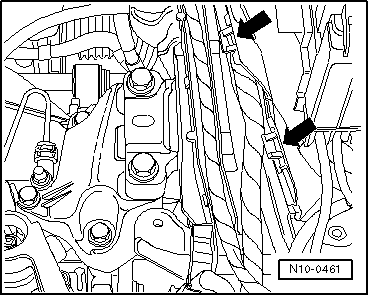

| All cable ties which are opened or cut through when engine is removed must be replaced in the same position when engine is installed. |

| –

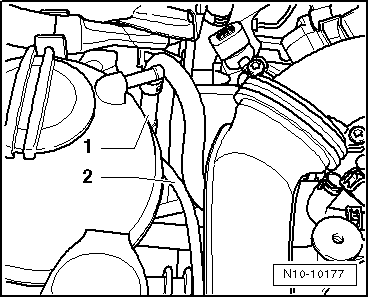

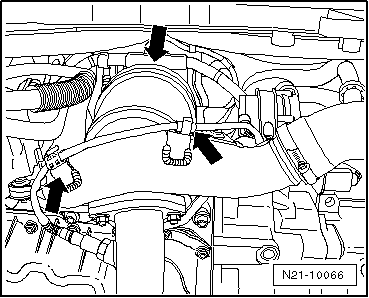

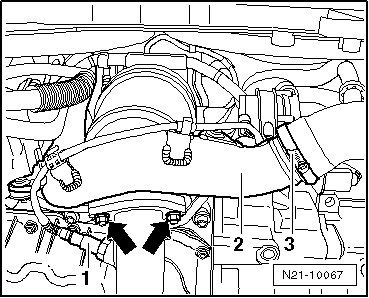

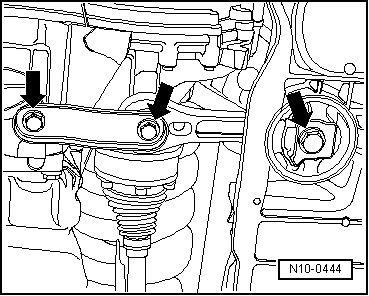

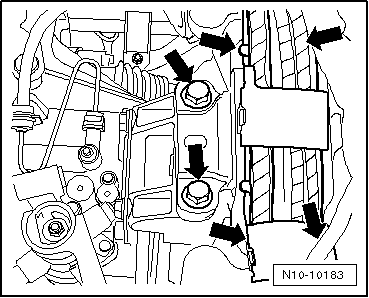

| Disconnect all electrical wiring from gearbox, alternator and starter and lay to side. |

| –

| Pull off or disconnect all other electrical connections as necessary from engine and lay to side. |

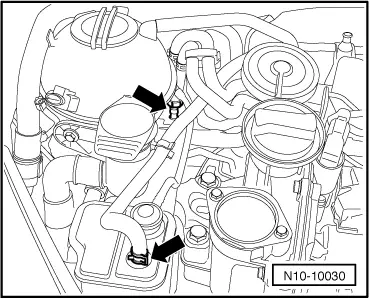

WARNING | Fuel supply lines are under pressure! Wear eye protection and gloves to avoid injuries and skin contact. Before loosening hose connections, wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

| –

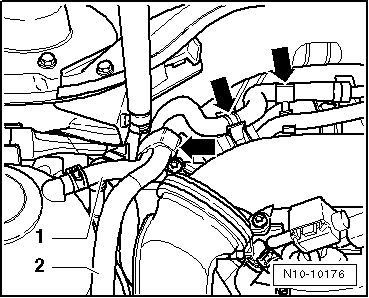

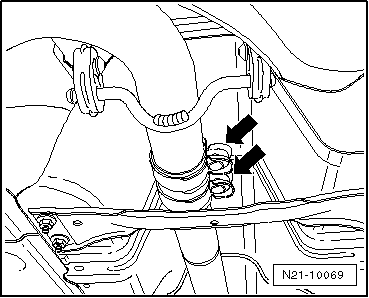

| Pull vacuum and breather hoses off engine. |

| –

| Pull connectors off thermal switch and radiator fan. |

| –

| Removing and installing anti-theft engine control unit (Golf) → Chapter. |

| –

| Removing and installing anti-theft engine control unit (Golf Plus, Touran) → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

WARNING

WARNING