| –

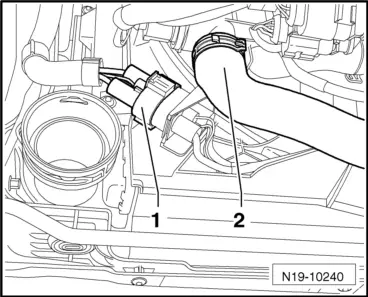

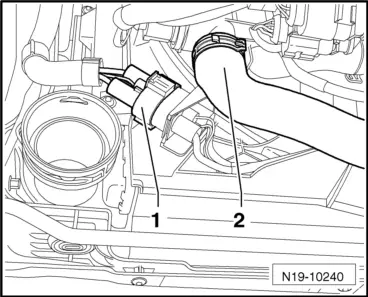

| Detach spring-type clip and pull off coolant hose -2-. |

Note | Observe environmental regulations for disposal. |

Note | The amount of water used in the coolant mixture has a great influence on its effectiveness. Because the water quality differs from country to country and even region to region, Volkswagen has decided to define the quality of the water to be used in the coolant system. Distilled water fulfils all requirements. It is therefore recommended that distilled water be mixed with the coolant when it is topped up or completely replaced. This also applies to older models. For new models (model year 2010 ▶) the use of distilled water is compulsory. |

Caution | Only distilled water may be mixed with G12 plus-plus. The use of distilled water ensures optimum protection against corrosion. |

|

Note | t

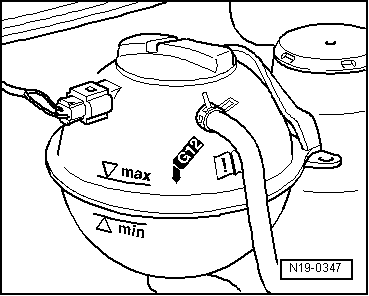

| In vehicles as of model year 2008, only G 12 plus-plus according to TL VW 774 G may be used as coolant additive. |

| t

| For vehicles up to and including model year 2007 coolant additive G 12 plus according to TL VW 774 F and G 12 plus-plus according to TL VW 774 G can be used. |

| t

| It is only permissible to use distilled water for mixing. |

| t

| The coolant additive G 12 plus-plus can be mixed with the previous coolant additive G 12 plus. Identification: both are coloured purple. |

| t

| Coolant additives marked conforming to „TL VW 774 G“ or conforming to „TL VW 774 F“ prevent frost and corrosion damage, scaling and also raise boiling point of coolant. Therefore, the cooling system must be filled all year round with frost and corrosion protection additives. |

| t

| Because of its higher boiling point, the coolant improves engine reliability under heavy loads, particularly in countries with tropical climates. |

| t

| Frost protection is required down to about -25°C (in countries with arctic climates: down to about -35°C). |

| t

| The coolant concentration must not be reduced by adding distilled water even in the warm season or in hot countries. The coolant additive concentration must be at least 40%. |

| t

| If for climatic reasons greater frost protection is required, the amount of coolant additive can be increased, but only up to 60 % (frost protection to about -40 °C). Otherwise frost protection and cooling effectiveness are reduced again. |

| t

| If radiator, heat exchanger, cylinder head or cylinder head gasket is renewed, do not reuse old coolant. |

| Recommended mixing ratios (use only distilled water for mixing): |

|

|

|

Note

Note Note

Note Note

Note

WARNING

WARNING Caution

Caution