| –

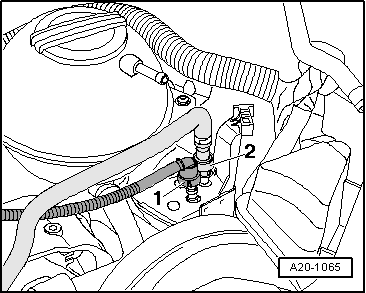

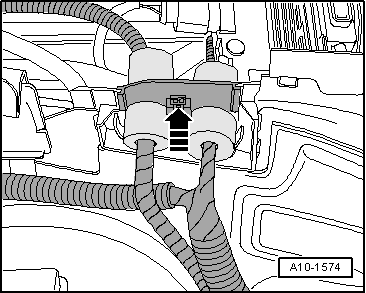

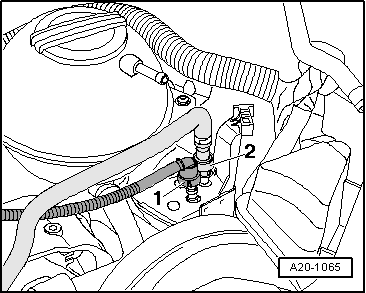

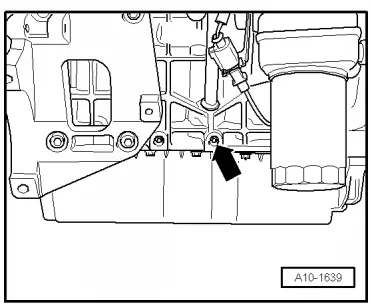

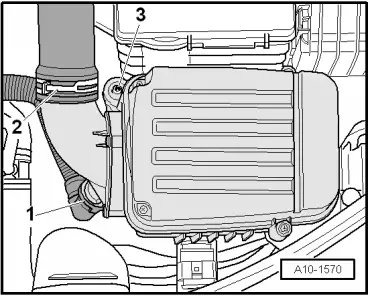

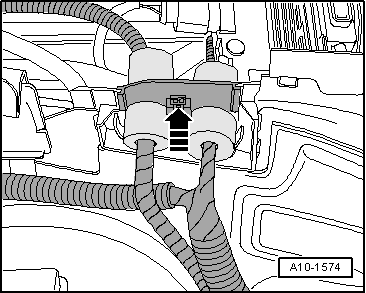

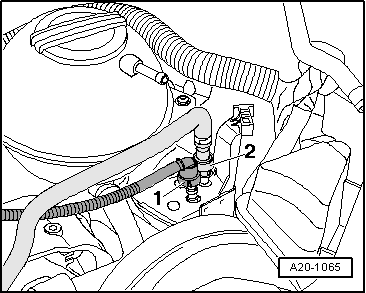

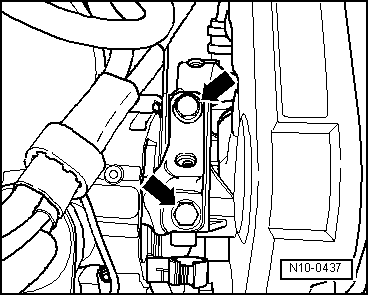

| Disconnect breather line -1- and fuel supply line -2- by pressing release buttons. |

| –

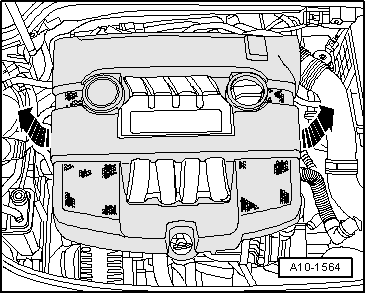

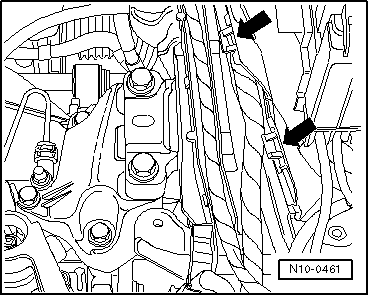

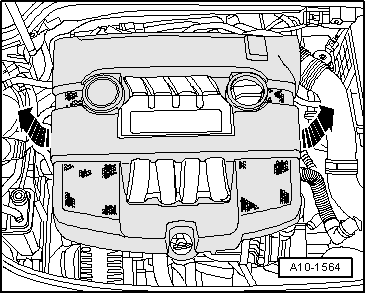

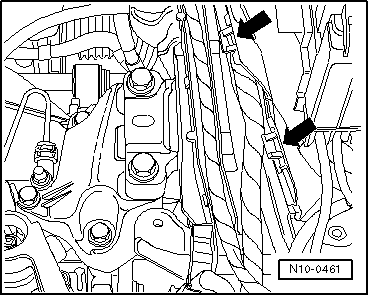

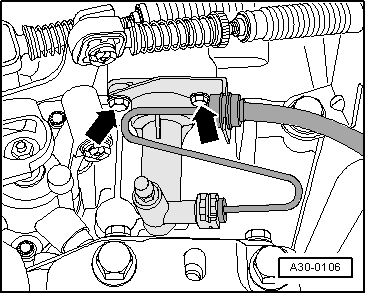

| Pull off or disconnect all other electrical lines from engine and gearbox as necessary and lay to side. |

| –

| Separate all connection, coolant, vacuum and intake hoses from engine. |

| Vehicles with air conditioning |

Note | To prevent damage to condenser and to refrigerant lines, ensure that lines are not stretched, kinked or bent. |

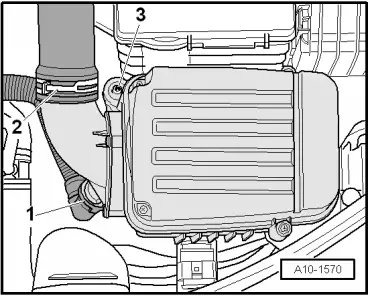

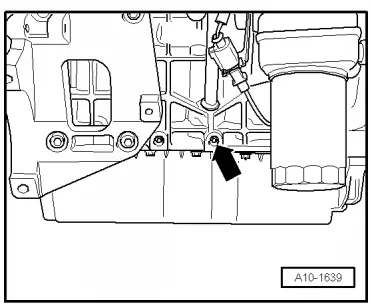

| Removing engine without opening refrigerant circuit: |

| –

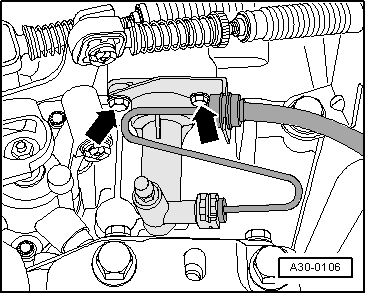

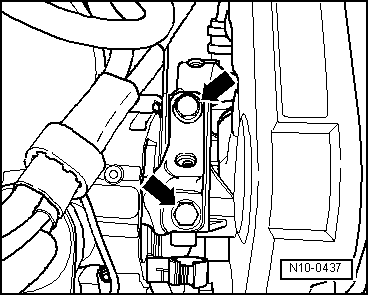

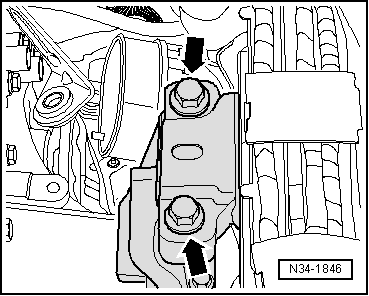

| Secure air conditioner compressor to lock carrier so that the refrigerant lines are not under tension. |

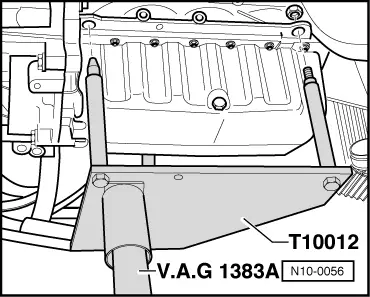

| Vehicles with manual gearbox: |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note