Golf Mk5

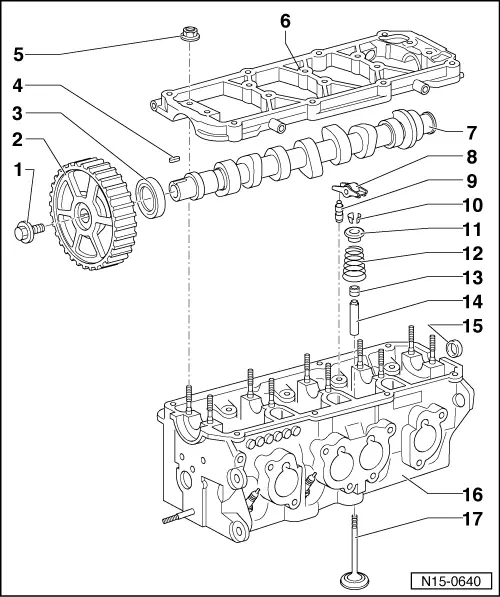

| Assembly overview - valve gear |

| 1 - | 100 Nm |

| q | Use counterhold tool -3415- to loosen and tighten. |

| 2 - | Camshaft toothed belt pulley |

| 3 - | Seal |

| q | Renewing → Chapter. |

| 4 - | Woodruff key |

| 5 - | 23 Nm |

| 6 - | Retaining frame |

| q | Reworking sealing surfaces is not permitted. |

| q | With integrated camshaft bearings. |

| q | Bearing 1 at belt pulley. |

| q | Observe tightening sequence of camshaft bearings → Chapter. |

| q | Carefully apply sealant D 188 800 A1 to sealant groove and lower sealing surface. |

| 7 - | Camshaft |

| q | Checking axial clearance → Chapter. |

| q | Removing and installing → Chapter. |

| q | Checking radial clearance with Plastigage; wear limit: 0.1 mm. |

| q | Runout: max. 0.04 mm. |

| 8 - | Roller rocker finger |

| q | Do not interchange. |

| q | Check roller bearing |

| q | Oil contact surface. |

| q | When installing, secure to support element using securing clip. |

| 9 - | Support element |

| q | Do not interchange. |

| q | With hydraulic valve clearance compensation. |

| q | Oil contact surface. |

| q | Checking → Chapter. |

| 10 - | Valve cotters |

| 11 - | Valve spring plate |

| 12 - | Valve spring |

| q | Cylinder head removed: Remove and install using valve spring compressor -2037-. |

| q | Cylinder head installed → Chapter. |

| 13 - | Valve stem seal |

| q | Renewing → Chapter. |

| 14 - | Valve guide |

| q | Checking → Chapter. |

| 15 - | Cover |

| q | Install flush. |

| q | To remove, pierce rubber centre with a screwdriver and lever out. |

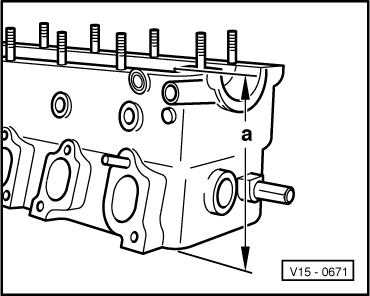

| 16 - | Cylinder head |

| q | Reworking camshaft-side sealing surfaces not permitted. |

| q | Reworking valve seats → Chapter. |

| 17 - | Valves |

| q | Do not rework, only lapping-in is permitted. |

| q | Valve dimensions → Chapter. |

|

|