Golf Mk5

Note

Note

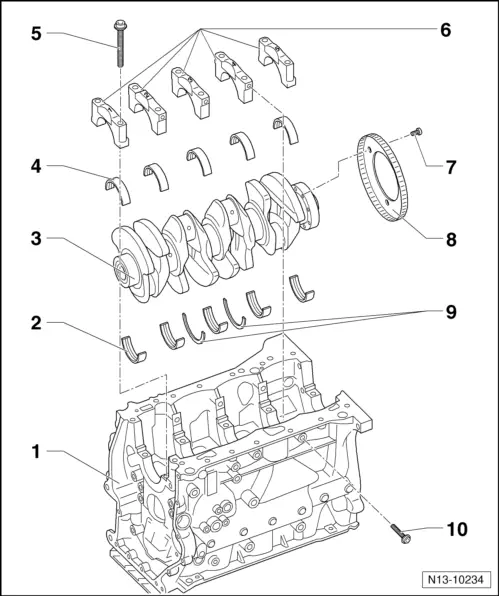

|

| 1 - | Cylinder block |

| q | If the cylinder block is renewed, the bearing shells must be reallocated to cylinder block → Chapter |

| 2 - | Bearing shell for cylinder block |

| q | With oil groove. |

| q | Do not interchange used bearing shells (mark). |

| q | Marking of crankshaft bearing shells → Chapter |

| 3 - | Crankshaft |

| q | After removing, place it down so that the sender wheel -item 5- is not damaged and the crankshaft does not rest on the sender wheel |

| q | If the crankshaft is renewed, the bearing shells must be reallocated to bearing cap → Chapter |

| q | Axial clearance → Chapter |

| q | Radial clearance → Chapter |

| q | Do not rotate crankshaft when checking radial clearance. |

| q | Crankshaft dimensions → Chapter. |

| q | Removing and installing → Chapter |

| 4 - | Bearing shell |

| q | Without oil groove. |

| q | Do not interchange used bearing shells (mark). |

| q | Marking of crankshaft bearing shells → Chapter |

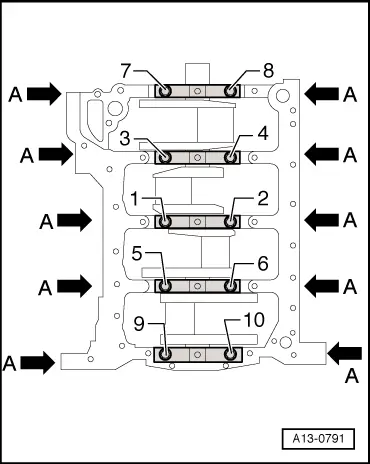

| 5 - | Bolt |

| q | Observe tightening sequence → Fig.. |

| q | Renew. |

| 6 - | Bearing cap |

| q | Bearing cap 1: belt pulley end. |

| q | Bearing shell retaining lugs in cylinder block and bearing caps must align. |

| 7 - | Bolt |

| q | 10 Nm + 1/4 turn (90°) further |

| q | Renew. |

| q | Sender wheel must be renewed if bolts are loosened → Chapter |

| 8 - | Sender wheel |

| q | For engine speed sender -G28-. |

| q | Can only be installed in one position, holes are offset. |

| q | Always renew sender wheel if securing bolts have been unscrewed. |

| q | Removing and installing → Chapter |

| 9 - | Thrust washers |

| q | For bearing 3. |

| 10 - | Bolt |

| q | Observe tightening sequence → Fig.. |

| q | Renew. |