| –

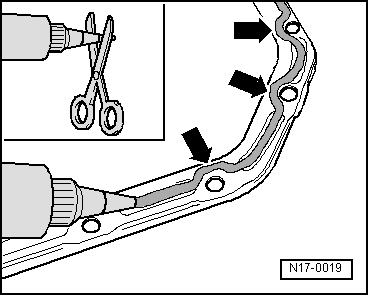

| Cut off tube nozzle at forward marking (approx. 3 mm nozzle Ø). |

| –

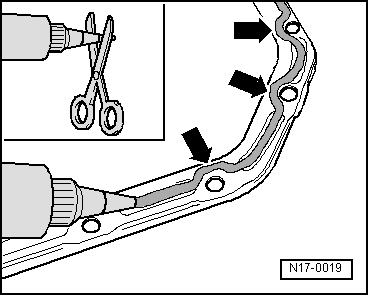

| Apply silicone sealing compound, as shown, onto clean sealing surface on sump. Sealant bead must be: |

| t

| Run bead along inner side of bolt holes -arrows-. |

Note | t

| The sealant bead must not be thicker, otherwise excess sealant will enter the oil sump and may block the oil suction line strainer. |

| t

| If gearbox is removed, sump must align smoothly with cylinder block. |

| t

| If gearbox is installed, sump must rest against gearbox. |

| t

| Let sealing compound dry for approx. 30 minutes after installing oil sump. Only then fill with engine oil. |

| –

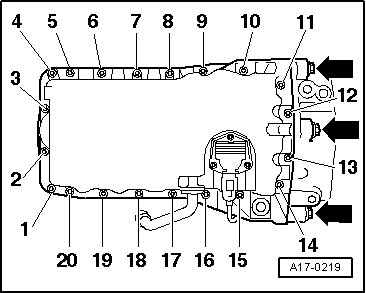

| Put sump in position immediately and tighten bolts as follows: |

| 1 - | Tighten all bolts between sump and cylinder block only very lightly and diagonally. |

| 2 - | Lightly tighten bolts securing sump to gearbox. |

| 3 - | Tighten all bolts securing sump to cylinder block slightly further in diagonal sequence. |

| 4 - | Tighten bolts securing sump to gearbox to 40 Nm. |

| 5 - | Tighten all bolts securing sump to cylinder block in diagonal sequence to 15 Nm. |

Note | t

| When installing sump with engine out of the vehicle, ensure that sump is flush with cylinder block at flywheel end. |

| t

| Let sealing compound dry for approx. 30 minutes after installing oil sump. Only then fill with engine oil. |

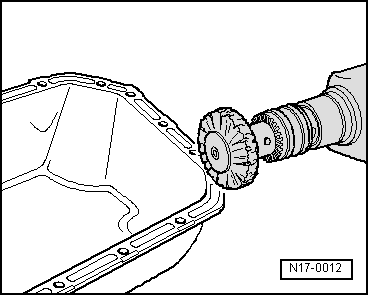

| Further assembly is basically the reverse of the dismantling procedure. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note