Golf Mk5

|

|

|

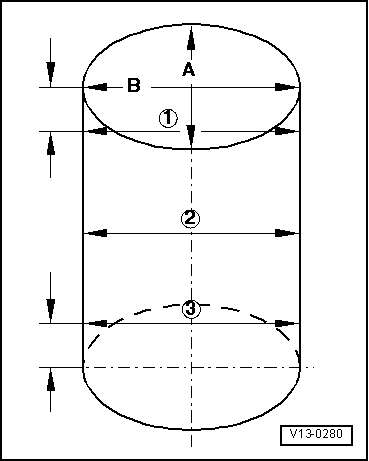

| Piston ring | Ring gap | ||

| new | Wear limit | ||

| Compression rings | mm | 0.20…0.40 | 0.8 |

| Oil scraper ring | mm | 0.25…0.50 | 0.8 |

|

|

| Piston ring | Clearance | ||

| new | Wear limit | ||

| Compression rings | mm | 0.06…0.09 | 0.20 |

| Oil scraper ring | mm | 0.03…0.06 | 0.15 |

Note

Note

|

|