| Engine codes BLX, BLY, BLR, BVX, BVY, BVZ: |

| –

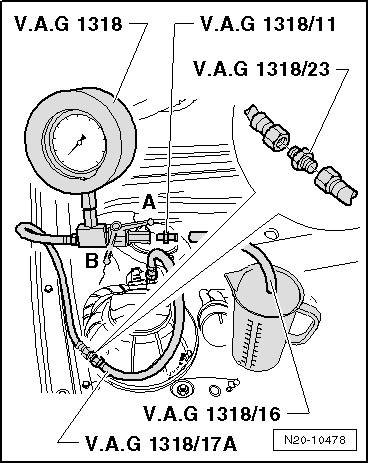

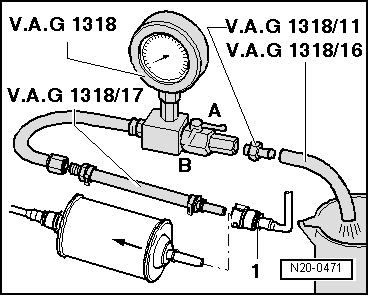

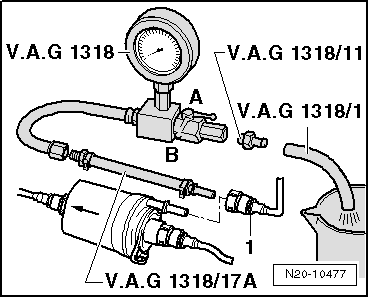

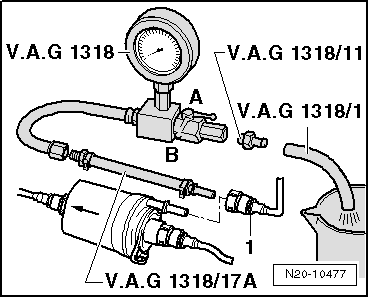

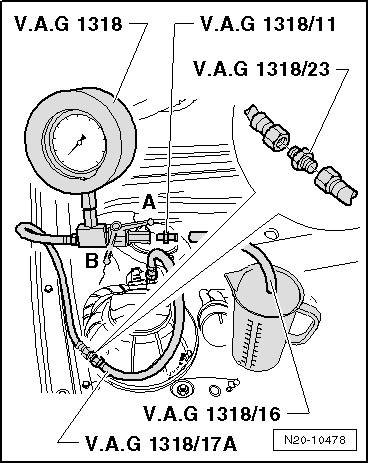

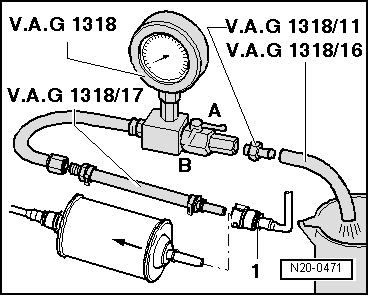

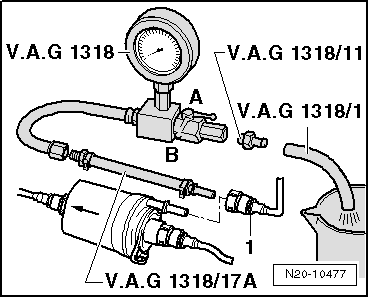

| Connect pressure tester -V.A.G 1318- with adapter set -V.A.G 1318/17A- to hose. |

| –

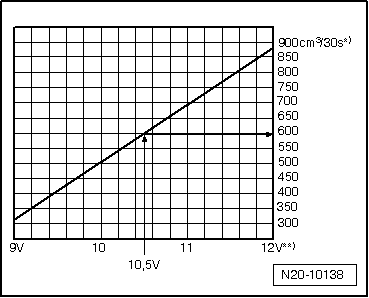

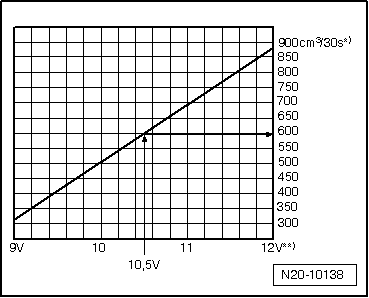

| Repeat delivery rate check. |

| If the minimum delivery rate is now attained: |

| If the minimum delivery rate is again not attained: |

| –

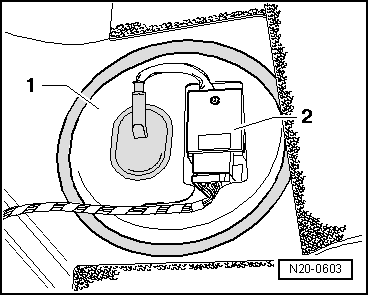

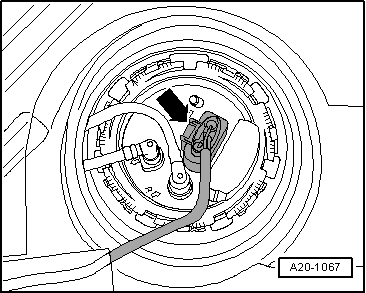

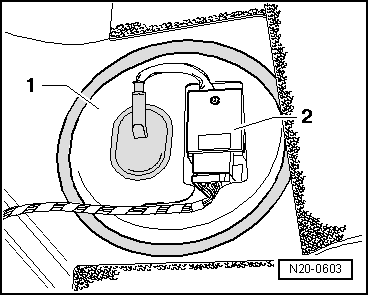

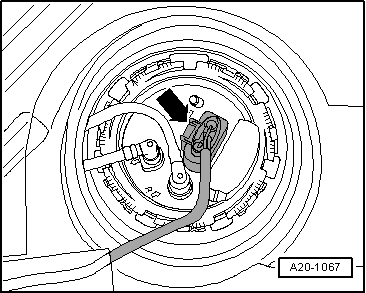

| Remove fuel delivery unit and check for dirt in filter strainer. |

| Only if still no fault has been detected: |

| –

| Renew fuel delivery unit. |

| If delivery rate has been attained, but nevertheless you suspect a fuel supply system fault (e.g. intermittent failure of fuel supply system): |

| –

| Measure current consumption of fuel pump → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note