Golf Mk5

Note

Note

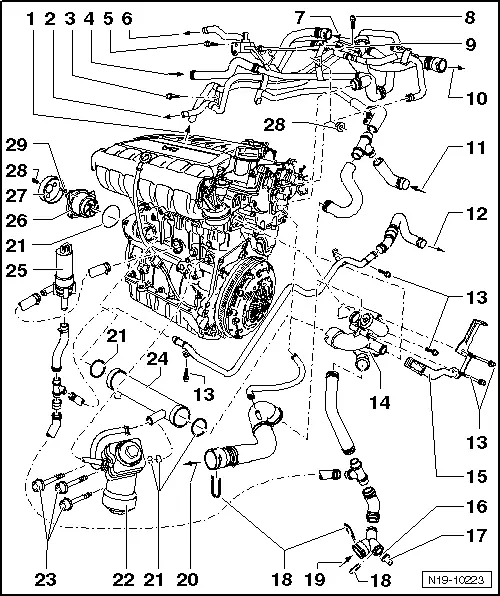

|

| 1 - | From auxiliary heater |

| q | Only vehicles with extra equipment |

| 2 - | To auxiliary heater |

| q | Only vehicles with extra equipment |

| 3 - | 45 Nm |

| 4 - | From bottom of expansion tank |

| 5 - | 10 Nm |

| 6 - | To top of expansion tank |

| 7 - | From heater coolant shut-off valve -N279- |

| q | Only vehicles with extra equipment |

| 8 - | 10 Nm |

| 9 - | To heater coolant shut-off valve -N279- |

| q | Only vehicles with extra equipment |

| 10 - | To heat exchanger |

| 11 - | From gearbox oil cooler |

| 12 - | To gearbox oil cooler |

| 13 - | 8 Nm |

| 14 - | Thermostat housing |

| q | Assembly overview - thermostat housing → Chapter |

| q | Removing and installing → Chapter. |

| 15 - | Retainer |

| 16 - | O-ring |

| q | Renew. |

| 17 - | Radiator outlet coolant temperature sender -G83- |

| 18 - | Retaining clip |

| q | Check for secure seating. |

| 19 - | From bottom of radiator. |

| 20 - | To top of radiator |

| 21 - | O-ring |

| q | Renew. |

| 22 - | Oil filter bracket |

| q | With oil cooler. |

| 23 - | 23 Nm |

| 24 - | Coolant pipe |

| q | To thermostat housing. |

| 25 - | Continued coolant circulation pump -V51- |

| q | Bolted to ancillary unit bracket to 8 Nm. |

| q | To remove, remove bracket for ancillaries → Heating, air conditioning; Rep. gr.87. |

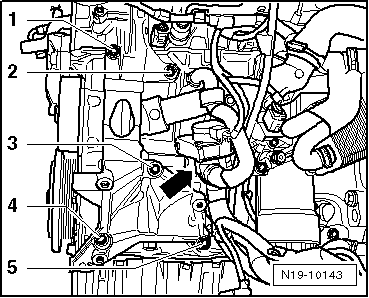

| q | Location of continued coolant circulation pump -V51- → Fig. |

| q | Checking continued coolant circulation pump -V51- → Chapter |

| 26 - | Coolant pump |

| q | Check for ease of movement. |

| q | Removing and installing → Chapter. |

| 27 - | Belt pulley |

| q | For coolant pump. |

| q | Removing and installing → Chapter, Removing and installing coolant pump |

| 28 - | 20 Nm |

| 29 - | 8 Nm |

|

|