Golf Mk5

| Removing and installing camshaft timing chain and intermediate shaft drive chain |

| Special tools and workshop equipment required |

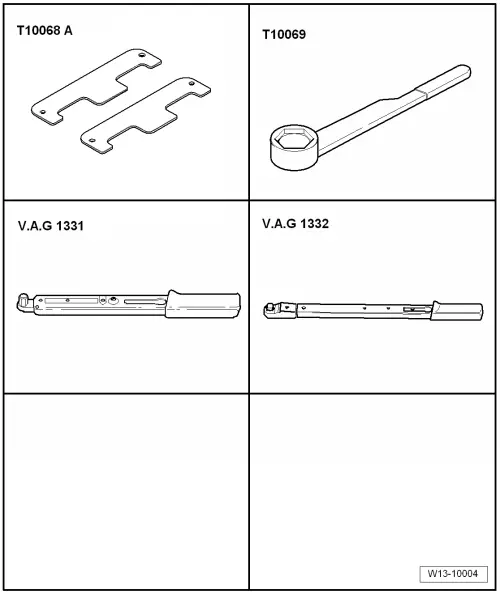

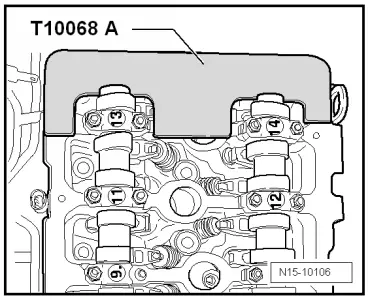

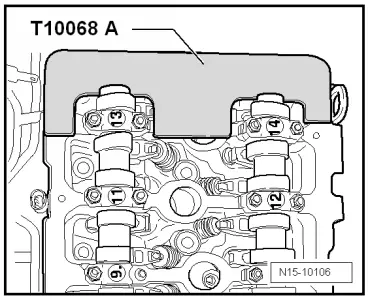

| t | Camshaft bar -T10068 A- |

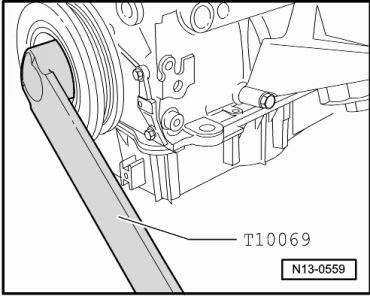

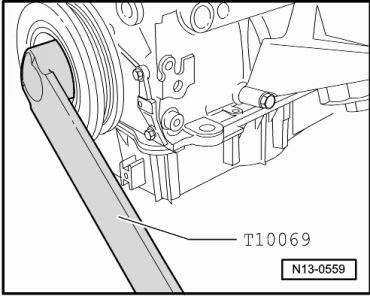

| t | Counterhold tool -T10069- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Sealant -D 176 501 A1- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

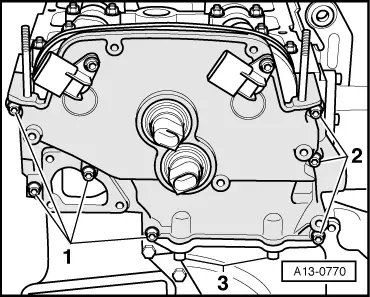

| Component | Nm | |

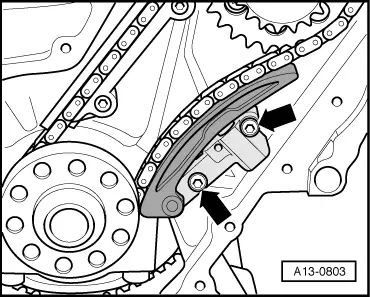

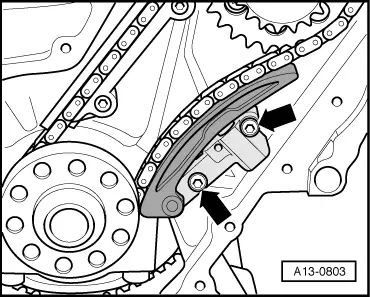

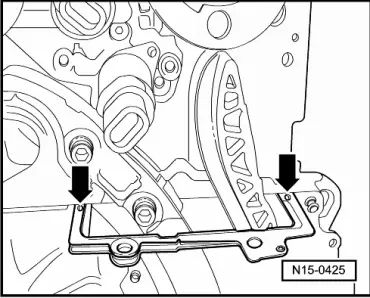

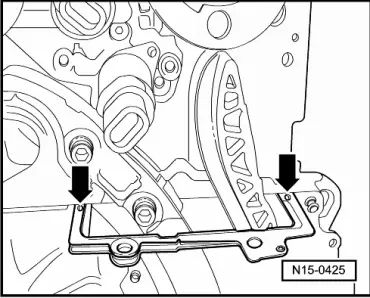

| Bolts for guide rail to cylinder block | 10 | |

| Chain tensioner to cylinder block | 8 | |

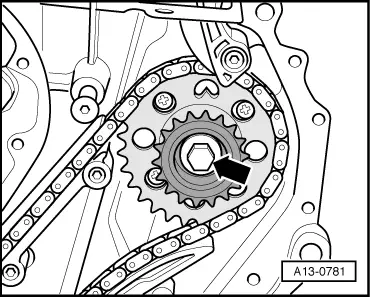

| Sprockets to intermediate shaft | 60 + 90° | |

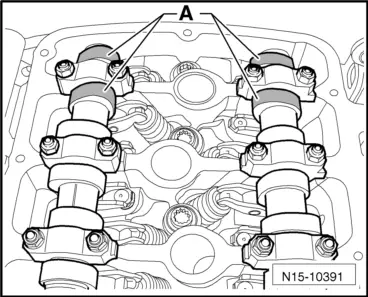

| Camshaft adjuster to camshafts | 60 + 90° | |

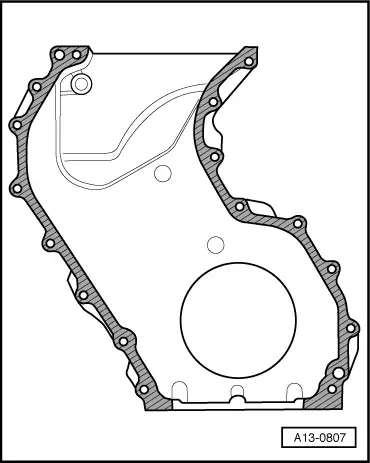

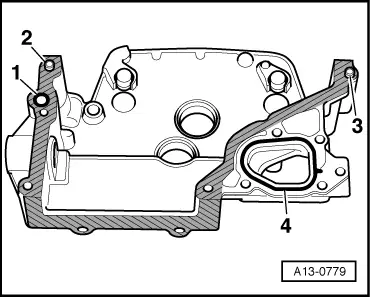

| Bottom cover for timing chains to cylinder block | 10 | |

| Top cover for camshaft timing chain | M6 | 10 |

| M8 | 23 | |

| Chain tensioner for camshaft timing chain to cylinder head | 40 | |