Golf Mk5

| Assembly overview |

| 1 - | 5 Nm + 1/8 turn (45°) further |

| 2 - | Exhaust camshaft bearing cap |

| q | Installation sequence → Chapter. |

| 3 - | Seal |

| q | Renew if leaking. |

| q | When installing valve timing housing, lightly lubricate contact surfaces of seal. |

| q | When replacing seals, do not spread too widely. |

| 4 - | Exhaust camshaft |

| q | Checking radial clearance with Plastigage; wear limit: 0.1 mm. |

| q | Runout: max. 0.04 mm. |

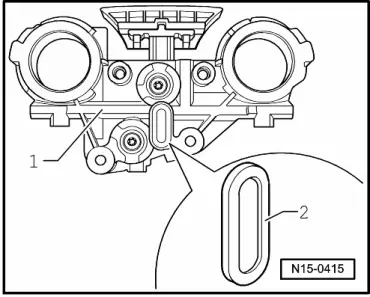

| q | Checking axial clearance → Fig.. |

| q | Identification and valve timing → Fig. |

| q | Removing and installing → Chapter. |

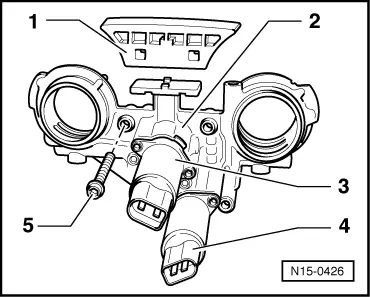

| 5 - | Valve timing housing |

| q | Lightly lubricate contact surfaces of oil seals before installing. |

| q | Dismantling and assembling → Fig.. |

| q | Before installing valve timing housing, check strainer for soiling → Fig.. |

| q | Removing and installing → Chapter. |

| 6 - | Camshaft timing chain |

| q | Before removing, mark direction of rotation (installation position) → Fig.. |

| q | Installing → Chapter. |

| 7 - | Exhaust camshaft adjuster |

| q | Identification: 32A. |

| q | Only rotate engine when camshaft adjuster is installed and chain is fitted |

| q | Installing → Chapter. |

| 8 - | 60 Nm + 1/4 turn (90°) further |

| q | Renew. |

| q | Contact surface of sender wheel must be dry around bolt head when installed. |

| q | To remove and install, counterhold with 32 mm open-end spanner on camshaft → Chapter |

| 9 - | Inlet camshaft adjuster |

| q | Identification: 24E |

| q | Only rotate engine when camshaft adjuster is installed and chain is fitted |

| q | Installing → Chapter. |

| 10 - | Cylinder head height |

| q | Minimum height: a = 139.9 mm. |

| 11 - | Valves |

| q | Do not rework, only lapping-in is permitted. |

| q | Valve dimensions → Fig.. |

| 12 - | Cylinder head |

| q | Check for distortion → Fig.. |

| q | Removing and installing → Chapter. |

| q | Reworking valve seats → Chapter. |

| q | After renewing, renew entire coolant. |

| 13 - | Support element |

| q | Before installing, check camshaft axial clearance → Fig.. |

| q | Do not interchange. |

| q | With hydraulic valve clearance compensation. |

| 14 - | Valve stem seal |

| q | Renewing → Chapter. |

| 15 - | Securing clip |

| q | Check for secure seating. |

| 16 - | Roller rocker finger |

| q | Before installing, check camshaft axial clearance → Fig.. |

| q | Do not interchange. |

| q | Check roller bearing for ease of movement. |

| q | Oil contact surface. |

| q | When installing, secure to supporting element using securing clip. |

| 17 - | Valve spring |

| q | Note installation position. |

| q | Removing and installing → Chapter. |

| 18 - | Valve spring plate |

| 19 - | Valve cotters |

| 20 - | Inlet camshaft bearing cap |

| q | Installation sequence → Chapter. |

| 21 - | Inlet camshaft |

| q | Checking radial clearance with Plastigage; wear limit: 0.1 mm. |

| q | Runout: max. 0.04 mm. |

| q | Checking axial clearance → Fig.. |

| q | Identification and valve timing → Fig. |

| q | Removing and installing → Chapter. |

|

|