| –

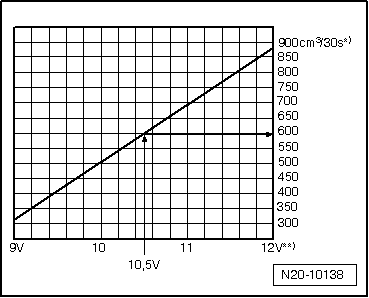

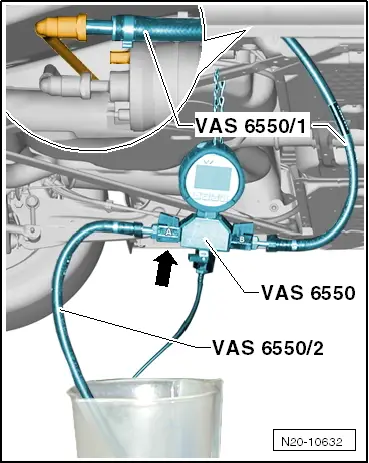

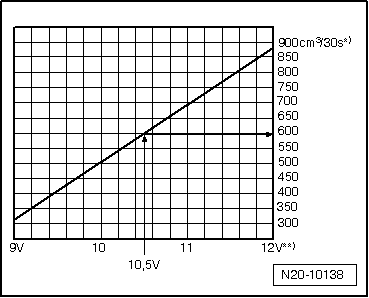

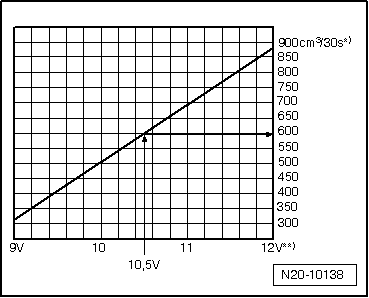

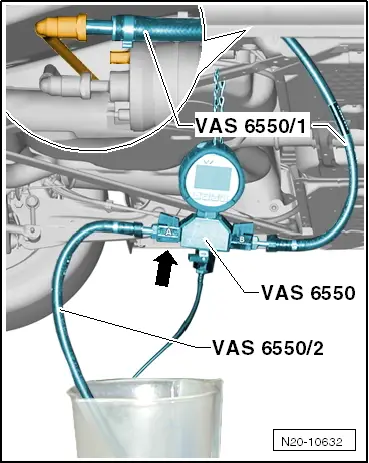

| Compare quantity of fuel delivered with specification. |

| *) Minimum delivery rate cm³/30 s |

| **) Voltage at fuel pump with engine not running and pump running (approx. 2 volts less than battery voltage). |

| During the test a voltage of 12.5 volts is measured at the battery. Because the voltage at the pump is approx. 2 volts less than the battery voltage, this will equate to a minimum delivery rate of approx. 580 cm³/30 s. |

| If the specification is not attained: |

| –

| Check supply line to filter for possible restrictions (kinks) or blockages. |

| –

| Remove cap from fuel filler neck and repeat check. If fuel delivery rate is now reached, check fuel tank breather. |

| If the specifications are still not attained: |

| –

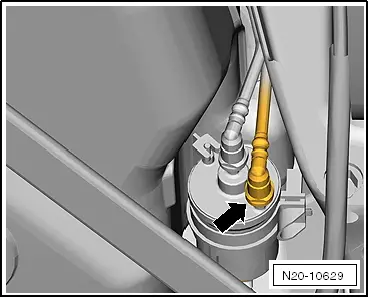

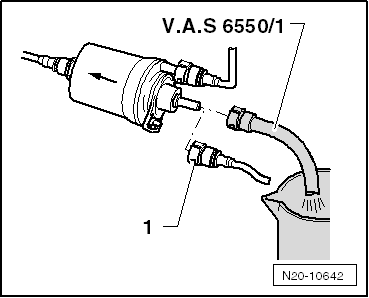

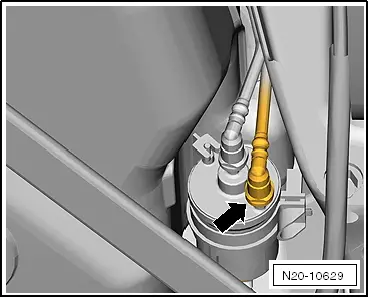

| Check fuel filter (proceed as follows): |

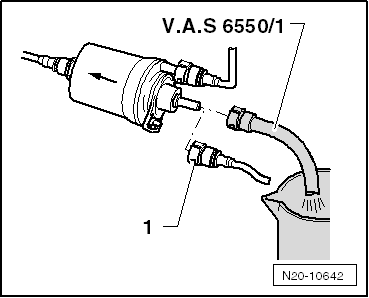

WARNING | Fuel supply line is pressurised. Wear eye protection and protective clothing to avoid possible injury and skin contact. Before loosening hose connections, wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection. |

|

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note