Golf Mk5

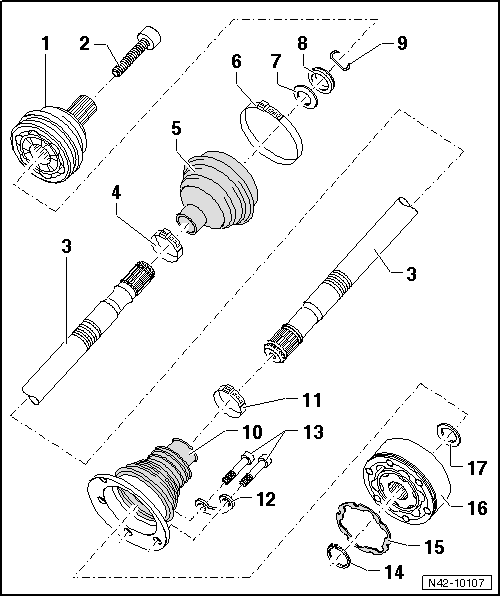

| Assembly overview: drive shaft |

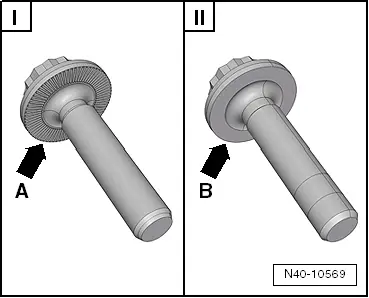

| 1 - | Outer constant velocity joint |

| q | Renew only as complete unit |

| q | Removing → Fig.. |

| q | Installing: drive onto shaft to stop using a plastic mallet |

| q | Checking → Chapter |

| 2 - | Bolt |

| q | Various versions |

| q | Allocation → Electronic parts catalogue „ETKA“ |

| q | M16 x 1.5 x 80 |

| q | Hexagon bolt, 180 Nm and turn +180° further |

| q | Loosening and tightening hexagon bolt for drive shaft → Chapter |

WARNING

WARNING

|

| 3 - | Drive shaft |

| q | Allocation → Electronic parts catalogue „ETKA“ |

| 4 - | Clamp |

| q | Always renew after removing. |

| q | Tightening → Fig. |

| 5 - | Boot |

| q | Check for splits and chafing |

| q | Material: (polyester elastomer). |

| 6 - | Clamp |

| q | Always renew after removing. |

| q | Tightening → Fig. |

| 7 - | Dished spring |

| q | Installation position → Fig.. |

| 8 - | Thrust washer |

| q | Installation position → Fig.. |

| 9 - | Retaining ring |

| q | Always renew after removing. |

| q | Insert in groove in shaft |

| 10 - | Boot for constant velocity joint |

| q | Material: Hytrel |

| q | Without breather hole |

| q | Check for splits and chafing |

| q | Drive off constant velocity joint with a drift |

| q | Coat sealing surface of constant velocity joint with -D 454 300 A2- before installing. |

| 11 - | Clamp |

| q | Always renew after removing. |

| q | Tightening → Fig. |

| 12 - | Locking plate |

| q | Always renew after removing. |

| 13 - | Bolt |

| q | Initially tighten diagonally to 10 Nm and then tighten diagonally to specified torque. |

| q | 40 Nm |

| q | Always renew bolts after removing |

| 14 - | Retaining ring |

| q | Always renew after removing. |

| q | Remove and install with circlip pliers -VW 161 A- |

| 15 - | Seal |

| q | Always renew after removing. |

| q | Adhesive surface on constant velocity joint must be free of oil and grease! |

| 16 - | Inner constant velocity joint |

| q | Renew only as complete unit |

| q | Pressing off → Fig. |

| q | Pressing on → Fig. |

| q | Checking → Chapter |

| 17 - | Dished spring |

| q | With inner splines |

| q | Installation position → Fig.. |