Golf Mk5

| Removing and installing rear axle |

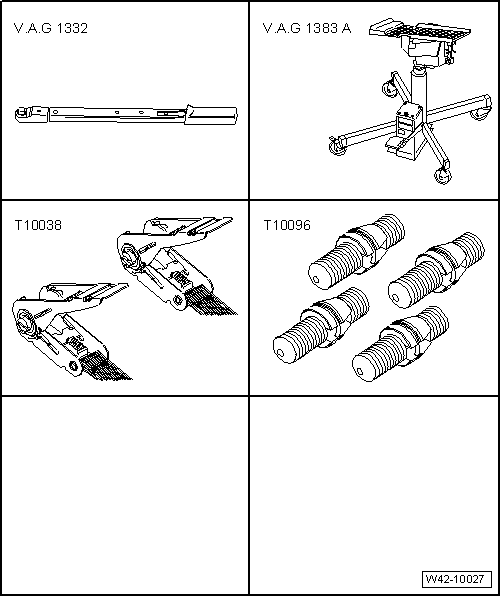

| Special tools and workshop equipment required |

| t | Torque wrench -V.A.G 1332- |

| t | Engine and gearbox jack -V.A.G 1383/A - |

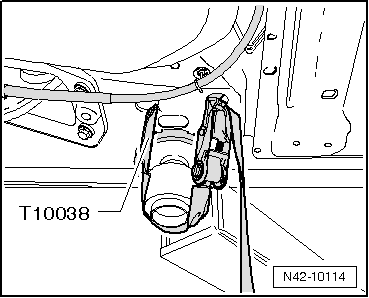

| t | Tensioning strap -T10038- |

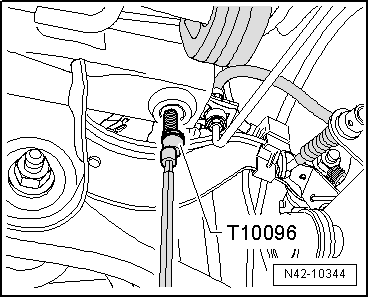

| t | Locating pins -T10096- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

| Specified torques |

| Component | Specified torque | ||

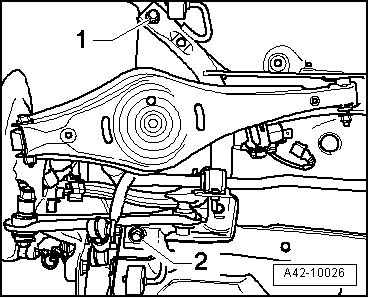

Subframe to body

| 90 Nm + 90° | ||

| Shock absorber to wheel bearing housing | 180 Nm | ||

Mounting bracket to body

| 50 Nm + 45° | ||

| Handbrake cable to trailing arm → Brake systems; Rep. gr.46 | |||

WARNING

WARNING