Golf Mk5

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Specified torques |

| Component | Specified torque | ||

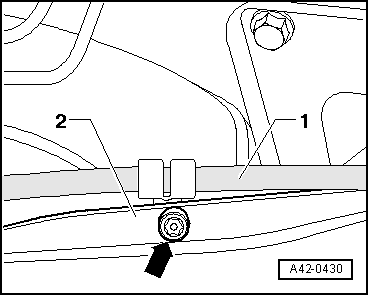

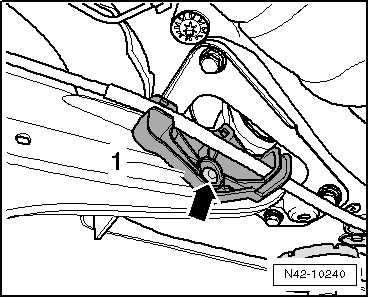

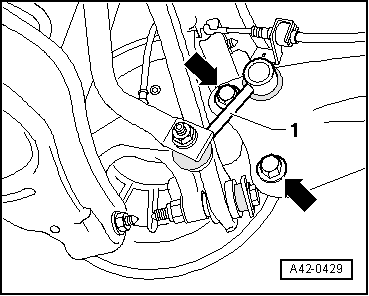

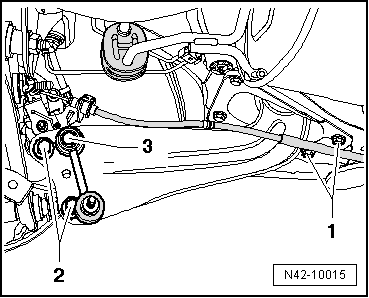

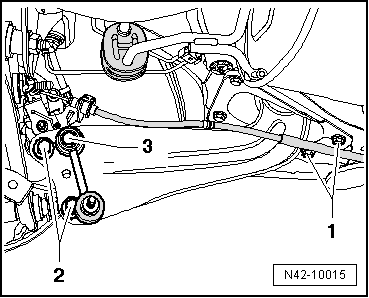

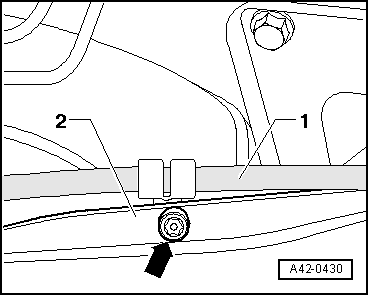

Trailing arm to wheel bearing housing

| 90 Nm + 45° | ||

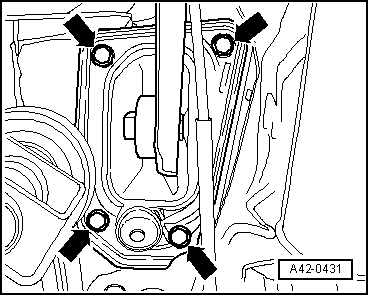

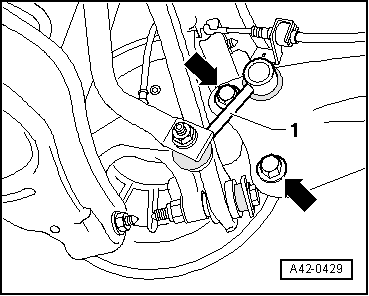

Trailing arm to mounting bracket

| 90 Nm + 90° | ||

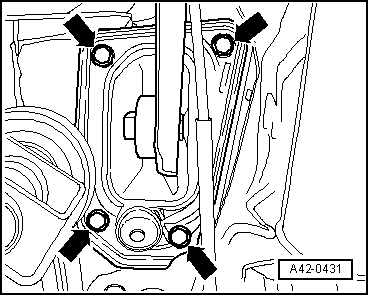

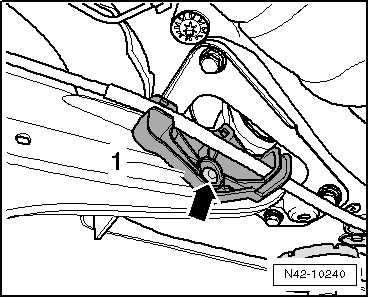

Mounting bracket to body

| 50 Nm + 45° | ||

Coupling rod to trailing arm.

| 45 Nm | ||

| Handbrake cable to trailing arm → Brake systems; Rep. gr.46 | |||