Golf Mk5

| Removing and installing track rod |

| Special tools and workshop equipment required |

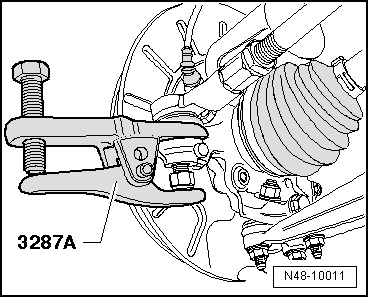

| t | Ball joint puller -3287 A- |

| t | Hose clip pliers -V.A.G 1275- |

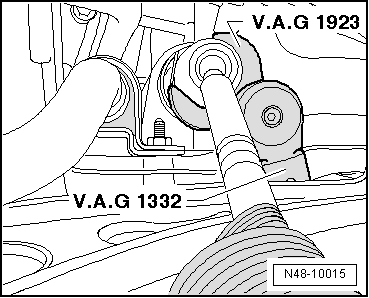

| t | Torque wrench -V.A.G 1332- |

| t | Open-end insert, 38 mm -V.A.G 1923- |

| t | Locking pliers for Phaeton steering box -VAS 6199- |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

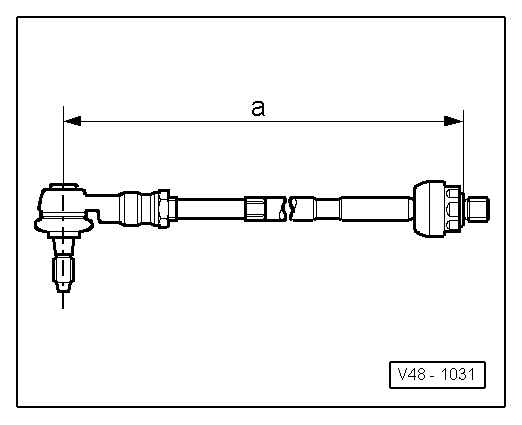

| Specified torques |

| Component | Specified torque | ||

| Track rod ball joint to track rod | 70 Nm | ||

Track rod ball joint to wheel bearing housing

| 20 Nm + 90° | ||

| Track rod to steering rack in steering box | 100 Nm |

Caution

Caution