| –

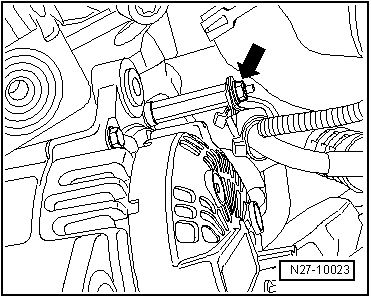

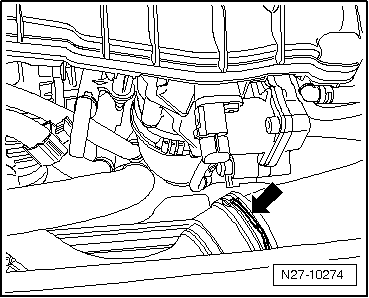

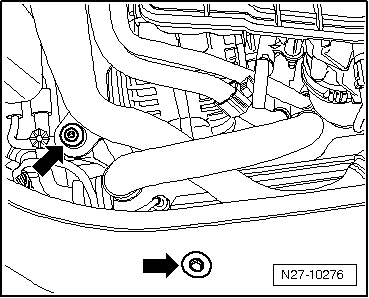

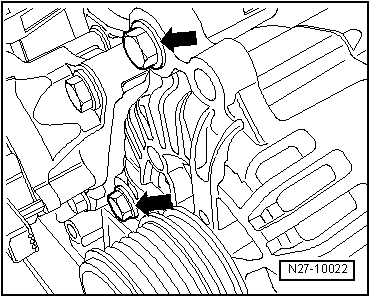

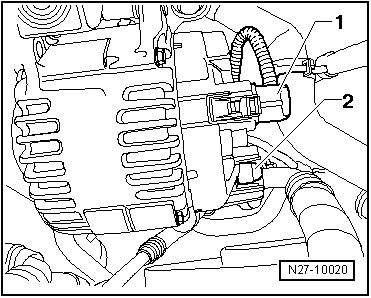

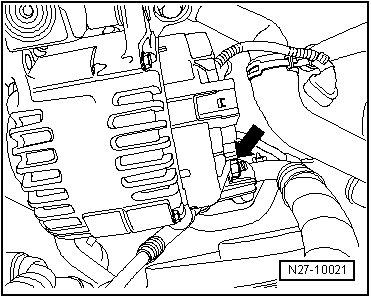

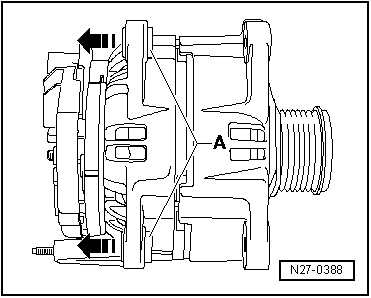

| Unscrew wiring retainer -arrow- from alternator. |

| –

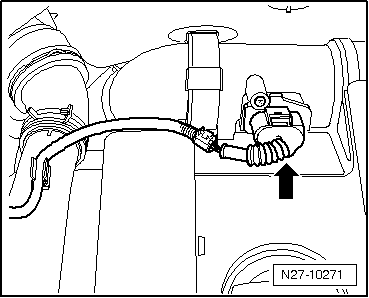

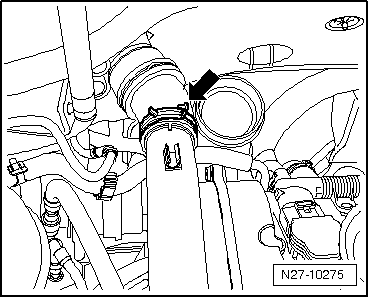

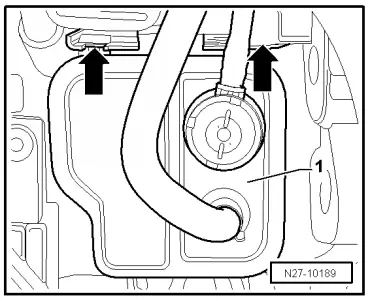

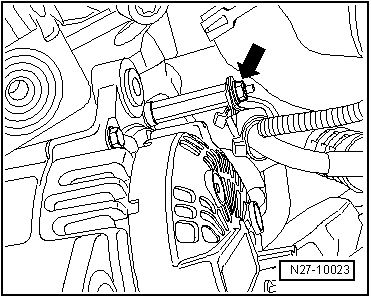

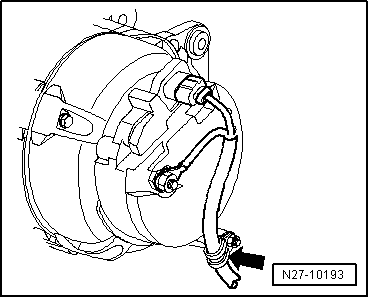

| Remove alternator from vehicle. |

| Install in the reverse order of removal. When doing this, note the following: |

Caution | t

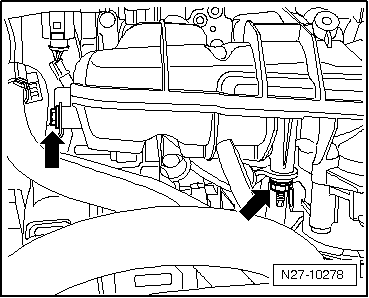

| In order to avoid damage to cylinder block and ancillaries bracket, adhere strictly to the tightening sequence for the ancillaries bracket → Chapter. |

| t

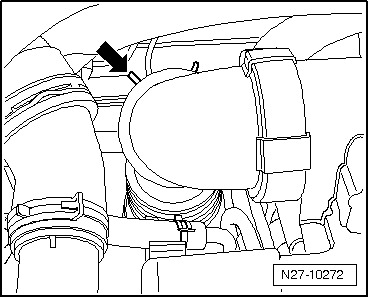

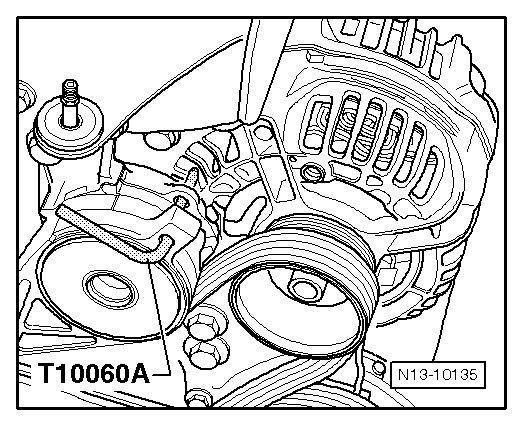

| When installing used poly V-belts observe the direction of rotation marked on removal! |

| t

| Before installing poly V-belt, ensure that all ancillaries (alternator, air conditioning compressor) are secure. |

| t

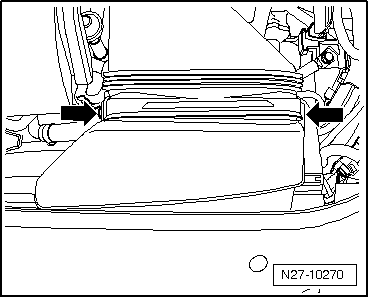

| When fitting belt, ensure that poly V-belt seats correctly in pulleys! |

|

|

|

|

Note

Note

Note

Note

Note

Note

Caution

Caution