| –

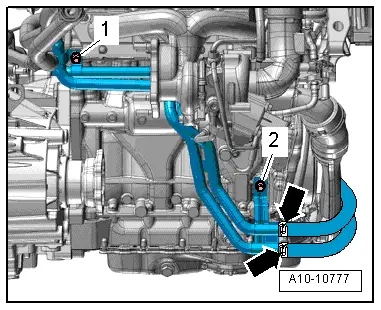

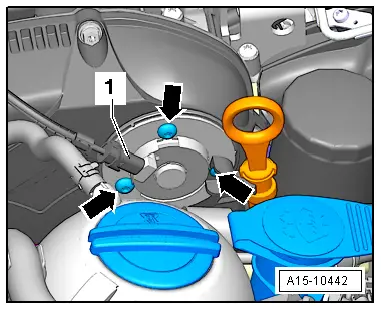

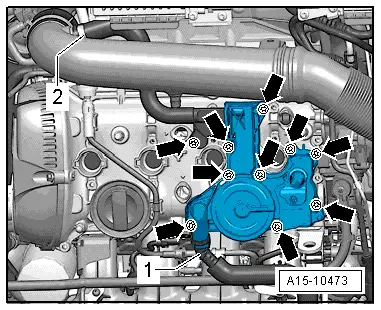

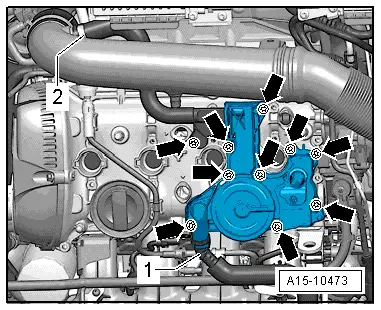

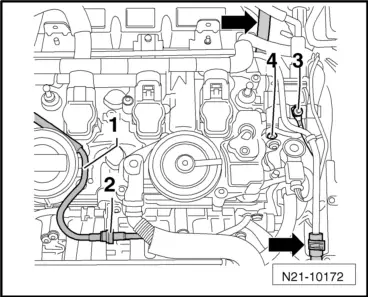

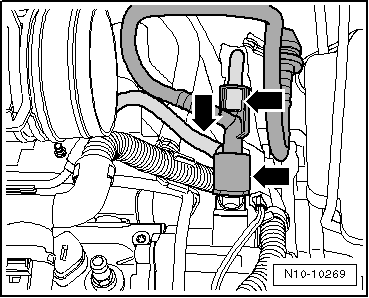

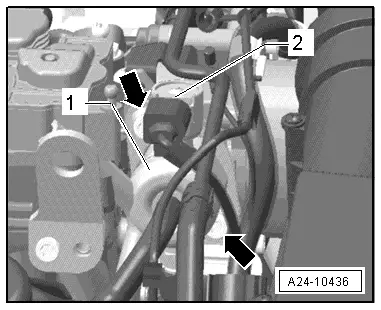

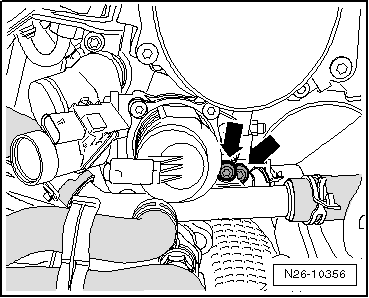

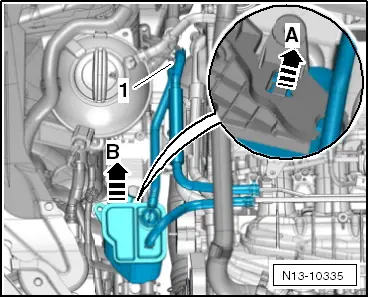

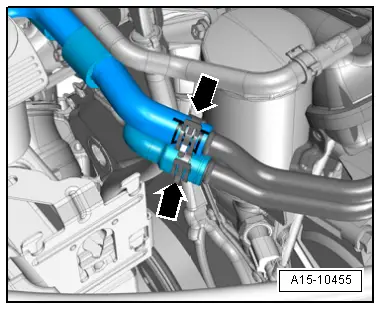

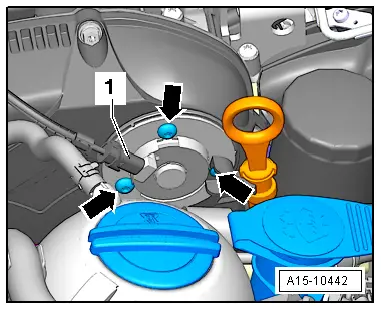

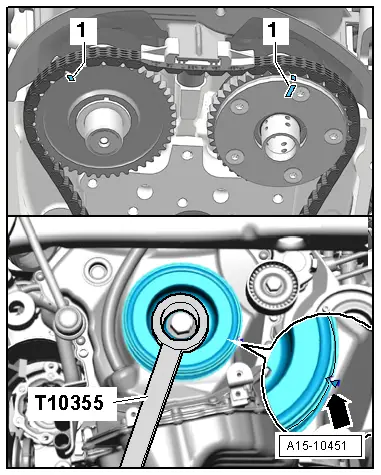

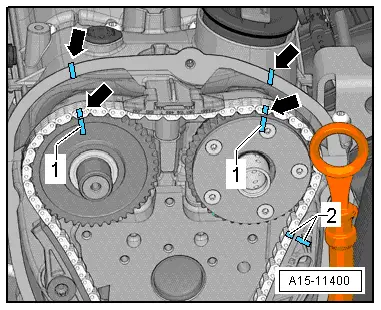

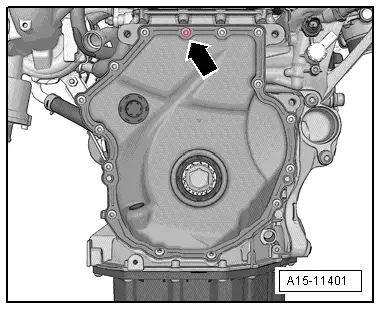

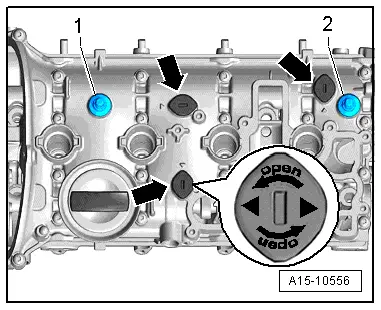

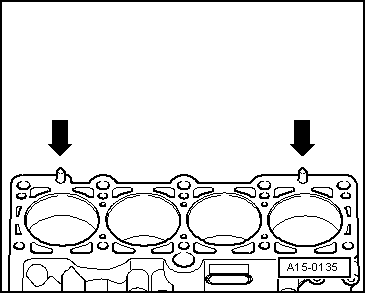

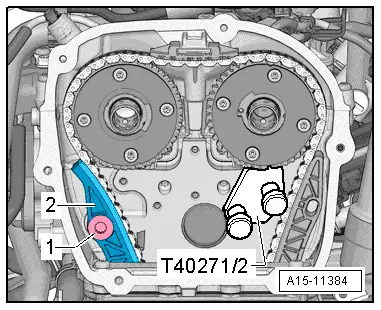

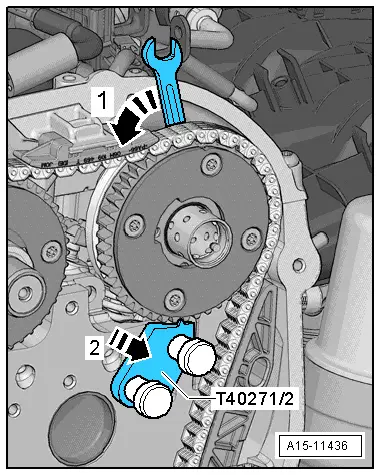

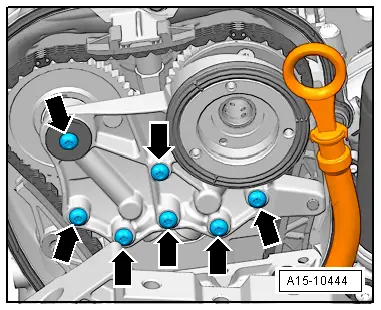

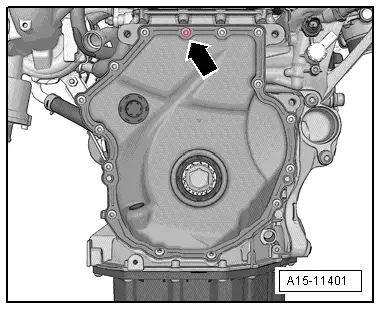

| Unscrew bolts -arrows-. |

| –

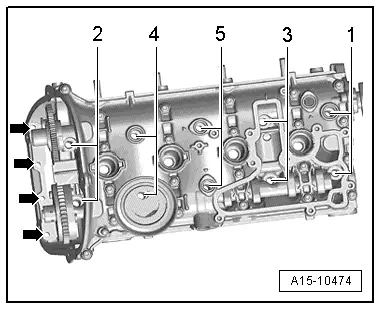

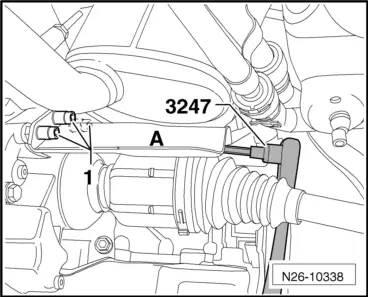

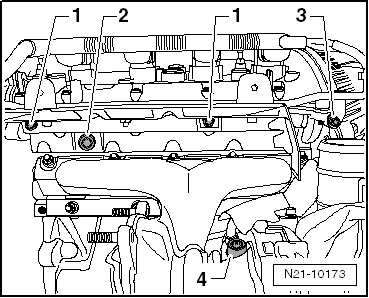

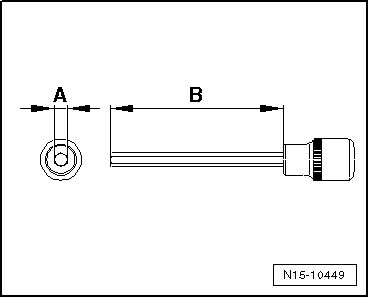

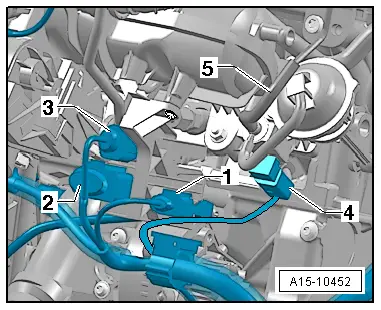

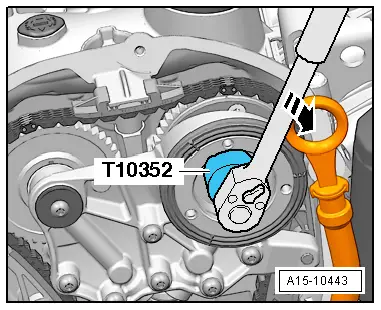

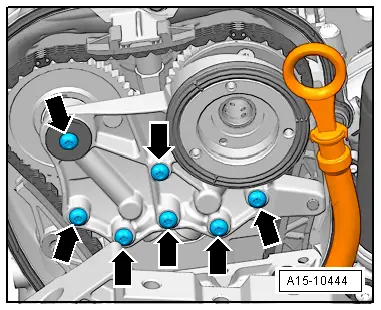

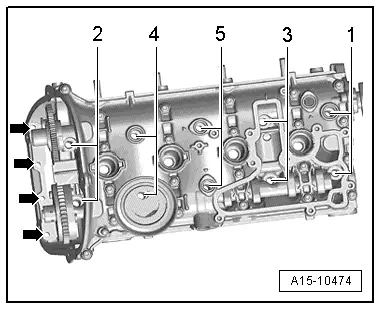

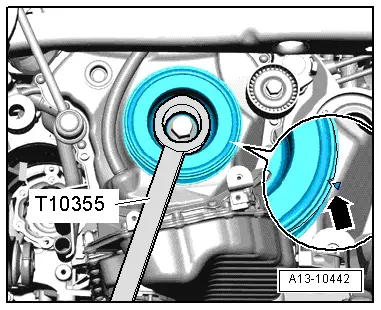

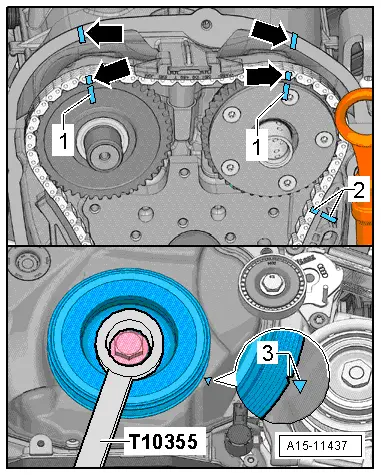

| Unscrew cylinder head bolts using polydrive bit and socket -T10070- in sequence -1 … 5-. |

Note | t

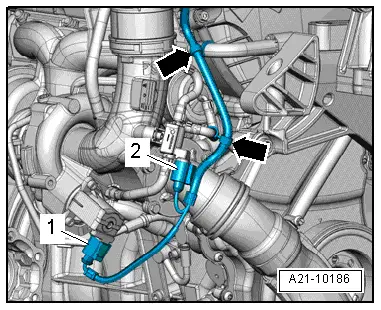

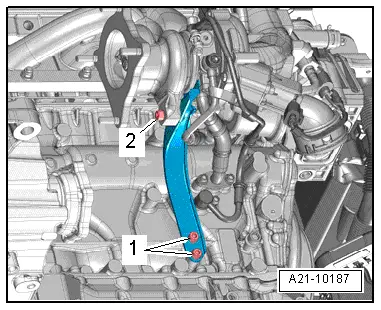

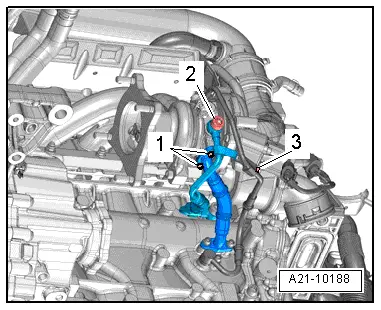

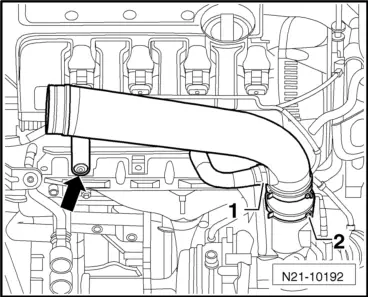

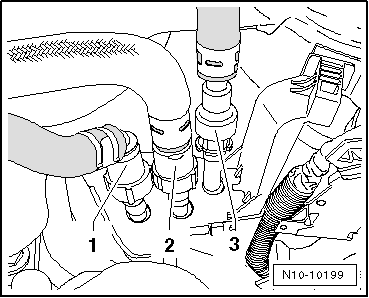

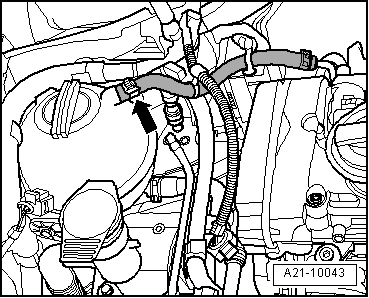

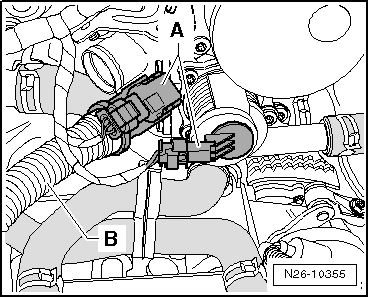

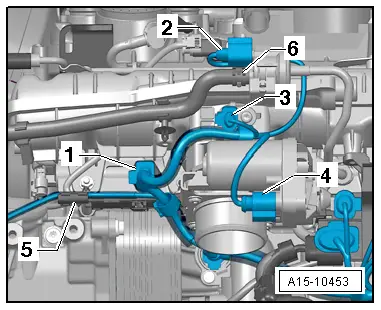

| Make sure all hoses/pipes and wiring on component are removed. |

| t

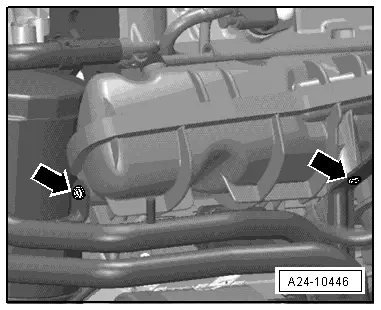

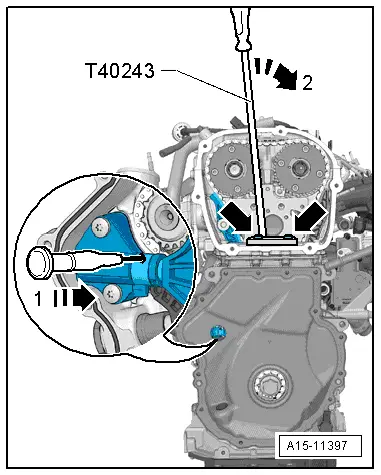

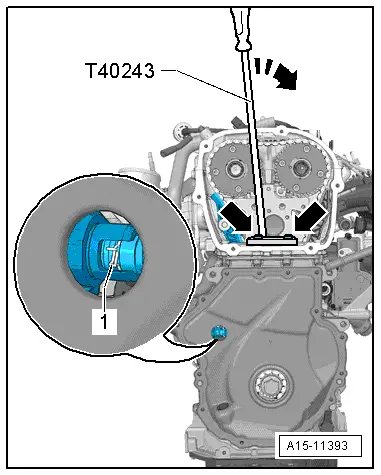

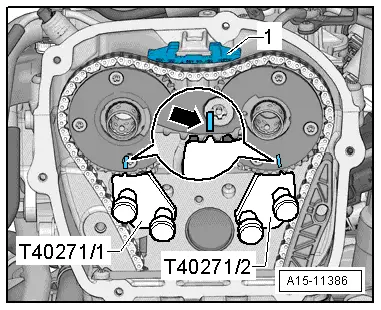

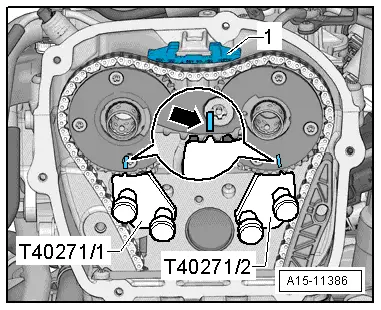

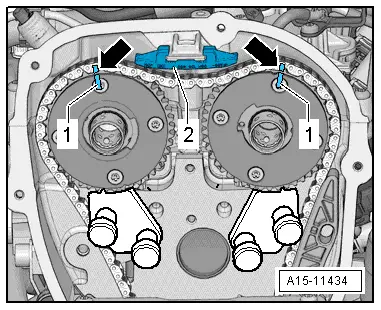

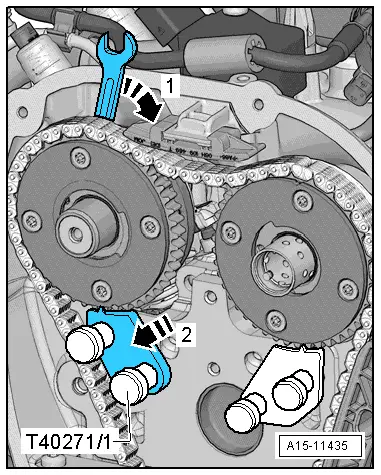

| Ensure tensioning rail and guide rail are not damaged when lifting off cylinder head. |

| –

| Place cylinder head onto soft surface (foam plastic). |

Caution | Avoid damage to sealing surfaces. |

| t

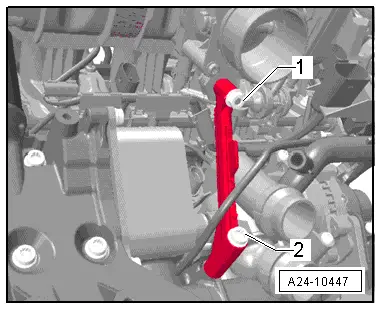

| Carefully remove sealant residue from cylinder head and cylinder block. |

| t

| Ensure that no long scores or scratches are made on the surfaces. |

| Avoid damage to cylinder block. |

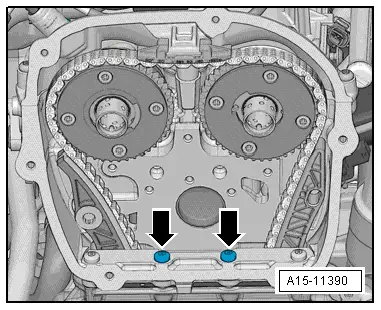

| No oil or coolant must be allowed to remain in the blind holes for the cylinder head bolts in the cylinder block. |

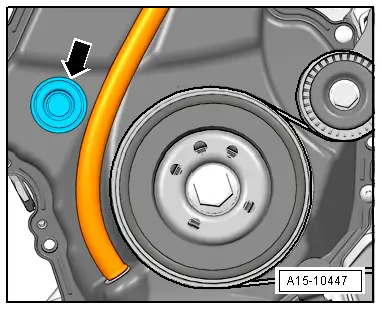

| Ensure that cylinder head gasket seals properly: |

| t

| Carefully remove remains of emery and abrasives. |

| t

| Do not remove new cylinder head gasket from packaging until it is ready to be fitted. |

| t

| Handle the cylinder head gasket very carefully to prevent damage to the silicone coating or the indented area of the gasket. |

| Avoid damage to open valves. |

| When installing an exchange cylinder head, the plastic protectors fitted to protect the open valves should not be removed until the cylinder head is ready to be fitted. |

| Avoid damage to valves and piston crowns after working on valve gear. |

| Turn the engine carefully at least 2 rotations to ensure that none of the valves make contact when the starter is operated. |

|

Note | t

| Renew bolts tightened with specified tightening angle. |

| t

| Renew self-locking nuts as well as gaskets, seals and O-rings. |

| t

| When installing a replacement cylinder head, the contact surfaces between hydraulic compensation elements, roller rocker fingers and cams must be oiled before installing the camshafts. |

| t

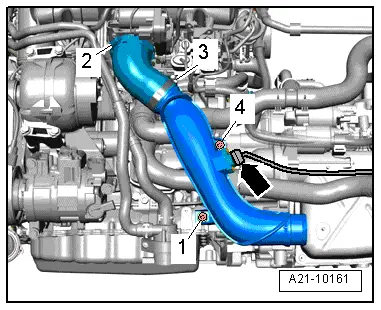

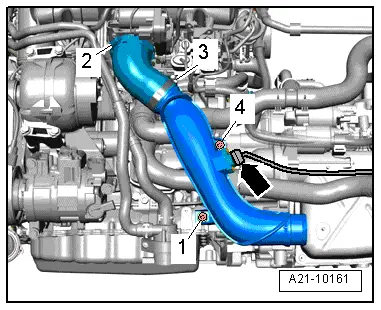

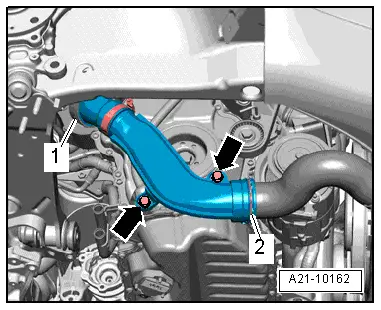

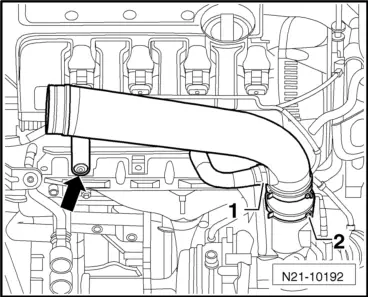

| Hose connections and air duct pipes must be free of oil and grease before assembly. |

| t

| In order to be in a position to securely attach the charge air hoses on their connections, the worm screws of the used hose clips have to the sprayed with penetrating spray before installing. |

| t

| When cylinder head or cylinder head gasket is renewed, the entire coolant and the engine oil must be changed. |

| Procedure for new cylinder head |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

Note

Note

WARNING

WARNING Caution

Caution