Polo Mk3

|

Checking charge pressure control

Checking charge pressure control

|

|

|

|

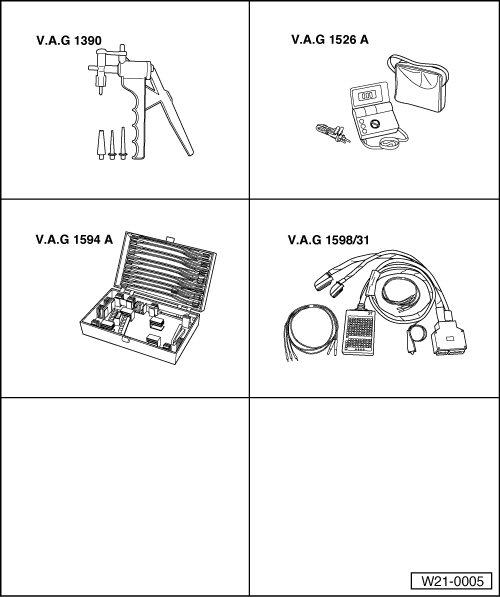

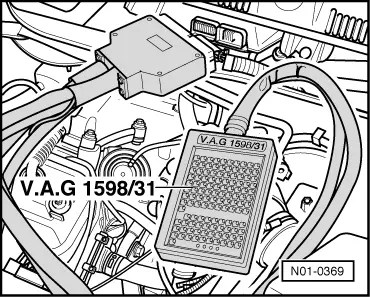

Special tools, workshop equipment, test and measuring appliances and auxiliary items required

Check conditions

=> Repair group 01; Self-diagnosis; Interrogating and erasing fault memory

Test sequence Observe following if test and measuring instruments are required during a test drive:

|

|

|

|

To enable the charge pressure control to be checked it is essential that the charge pressure is first determined with charge pressure control deactivated.

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

|

| → Specification in display zone 3: 1550...1750 mbar |

|

||

|

If the charge pressure is not attained:

If the charge pressure has still not been attained:

If the charge pressure is exceeded:

Note: Separating connector on solenoid valve for charge pressure control -N75- causes a fault to be recorded. Interrogate and erase fault memory.

=> Repair group 01; Self-diagnosis; Interrogating and erasing fault memory

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

|

| → Specification on V.A.G 1551: 1800...2200 mbar (in display zone 3) |

|

||

|

If the specification is not obtained:

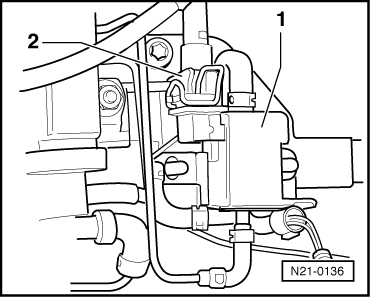

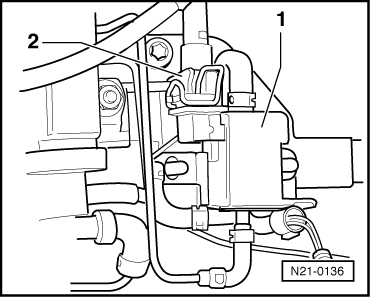

Checking solenoid valve for charge pressure control (N75) |

|

|

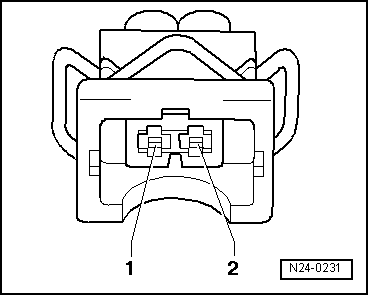

Specification: 25...45ω If the specification is not obtained:

|

|

|

|

If the specification is obtained:

If the specification is not obtained:

|

|

|

If no fault is detected in the wiring:

=> Repair group 23; Renewing engine control unit, coding and matching; Renewing engine control unit |