Polo Mk3

|

Dismantling and assembling differential

Removing and installing final drive gear wheel

|

|

|

|

Removing

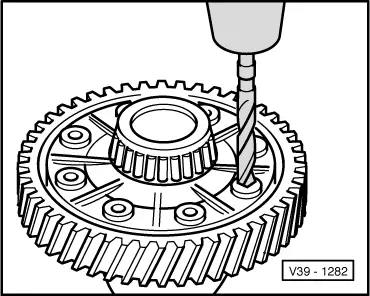

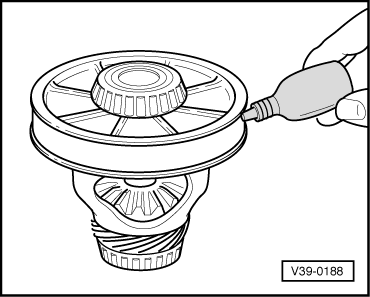

Note: Clean differential before and after drilling, protect taper roller bearing from drillings. |

|

|

|

|

|

Installing |

|

|

|

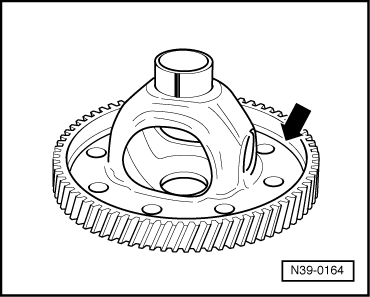

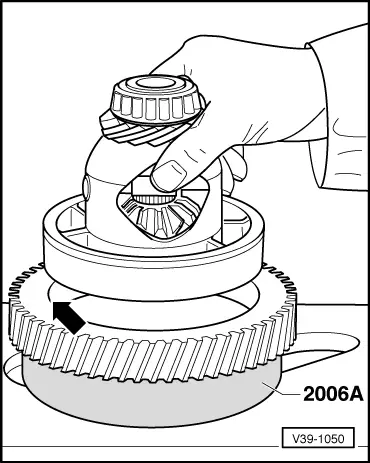

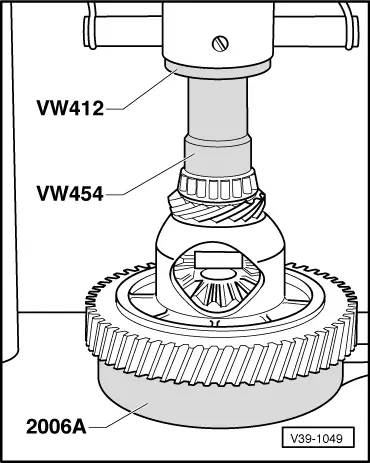

When renewing the final drive gear ensure correct ratio (number of teeth) . Installation position:

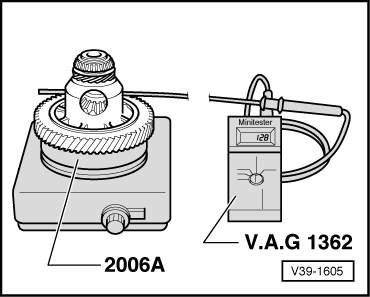

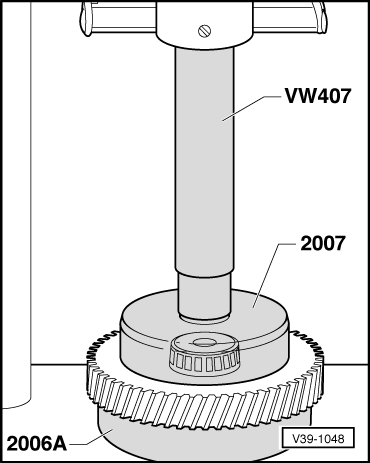

Gearboxes with bonded final drive gear wheel |

|

|

|

|

|

Notes:

|

|

|

Gearboxes with bolted final drive gear wheel

Tightening torque Final drive gear to differential 70 Nm |