Polo Mk3

|

Dismantling and assembling 3rd and 4th gear clutch -K3-

Dismantling and assembling 3rd and 4th gear clutch -K3-

|

|

|

|

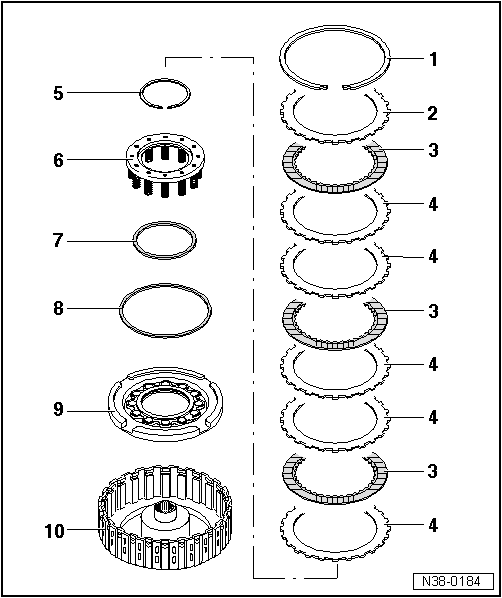

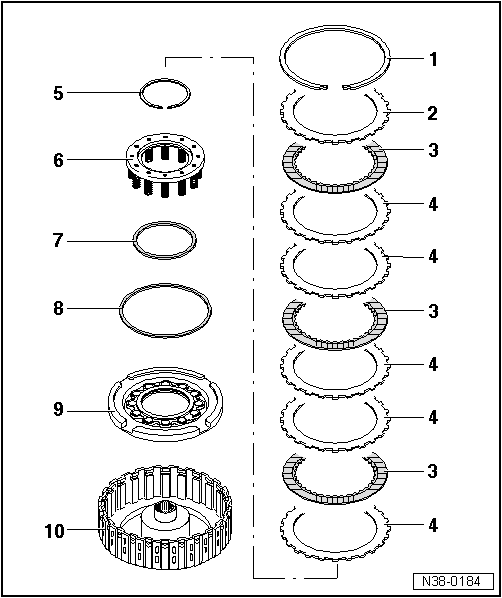

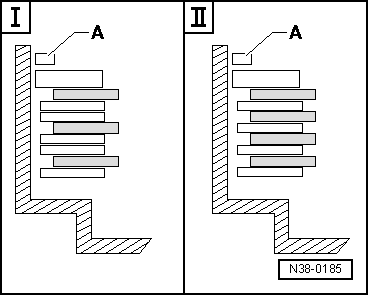

Take note of number of plates and location during dismantling stage => figure 2 . Functional check of clutch =>Fig.5 |

|

|

|

|

|

|

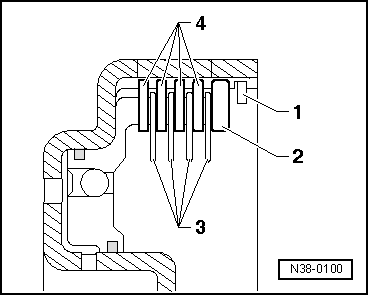

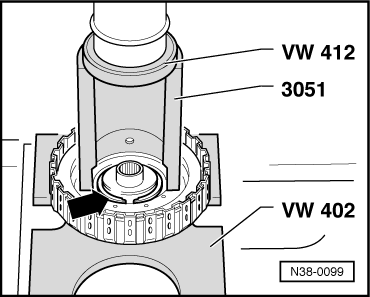

→ Fig.1 Removing and installing circlip (arrow)

|

|

|

|

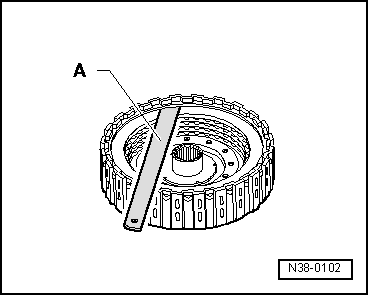

→ Fig.2 Observe different number and location of plates I - -K3- with 3 inner plates II - -K3- with 4 inner plates A - Circlip |

|

|

|

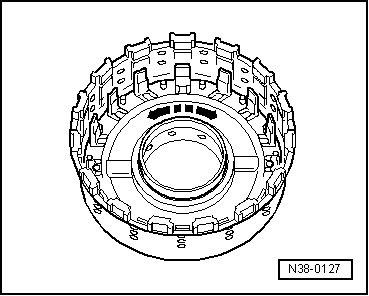

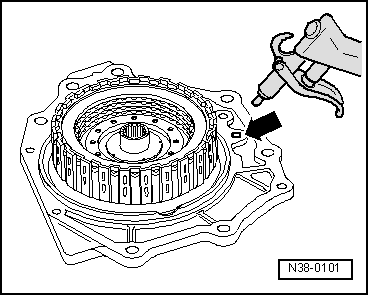

→ Fig.5 Functional check of clutch

|

|

|

|