Polo Mk3

| Checking exhaust gas recirculation |

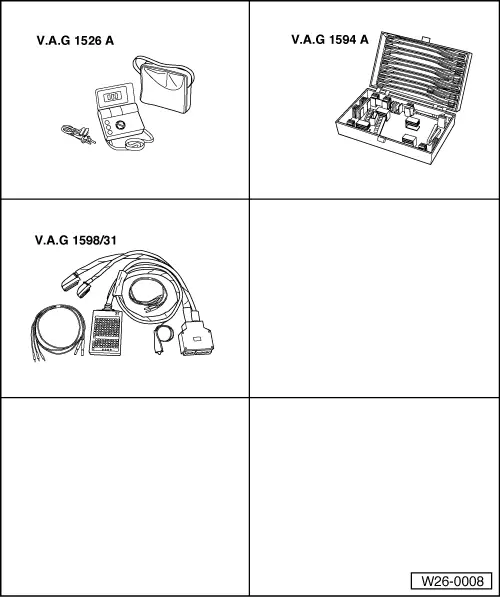

| Special tools and workshop equipment required |

| t | Hand multimeter -V.A.G 1526A- or hand multimeter -V.A.G 1526C- |

| t | Auxiliary measuring set -V.A.G 1594A- or auxiliary measuring set -V.A.G 1594C- |

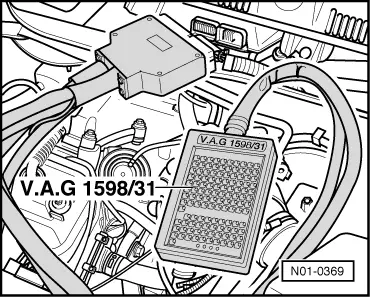

| t | Adapter cable, 121-pin -V.A.G 1598/31- |

| t | Fault reader -V.A.G 1551- |

| t | Diagnosis lead -V.A.G 1551/3C- |

| t | Current flow diagram |

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|