Polo Mk3

|

Servicing valve gear

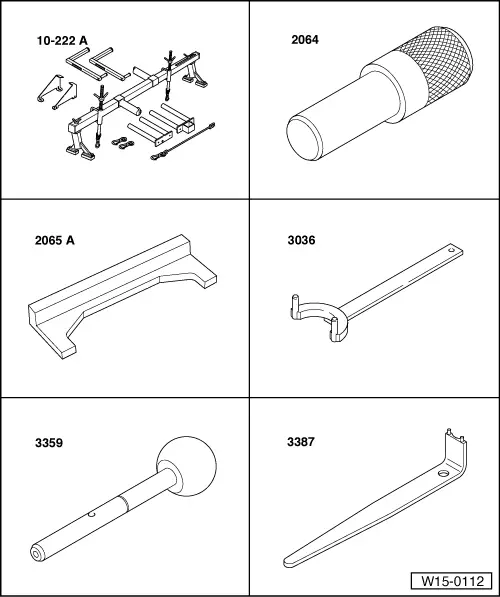

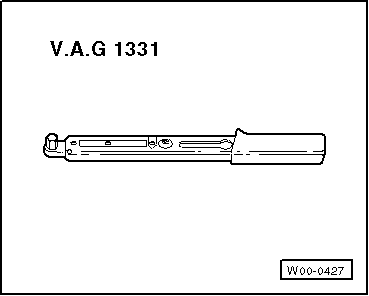

Removing and installing camshaft

|

|

|

Removing

Note: It is not necessary to remove ribbed belt, vibration damper/belt pulley and lower toothed belt guard. |

|

|

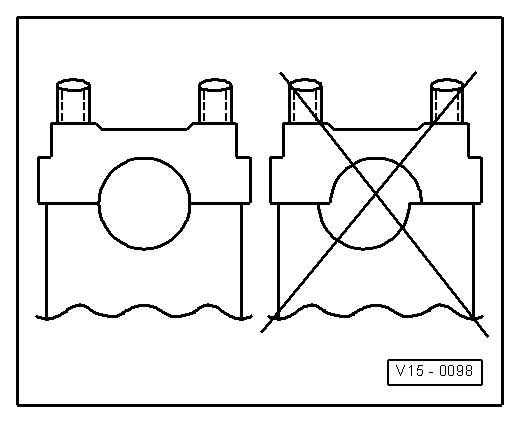

Installing Notes:

The rest of the assembly is basically a reverse of the dismantling sequence.

Installing toothed belt and adjusting timing => Page 15-11 , Removing, installing and tensioning toothed belt. Note: When new tappets have been installed the engine must not be started for about 30 minutes. Hydraulic compensation elements must settle (otherwise valves will strike pistons). |