Polo Mk3

|

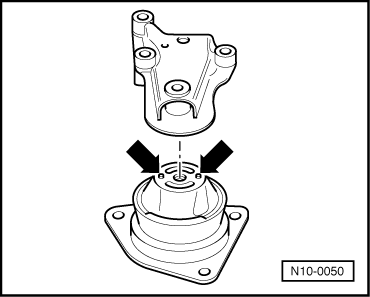

Removing and installing engine

Notes on installing

Installation is carried out in the reverse sequence, when doing this note the following: Vehicles with manual gearbox

Vehicles with automatic gearbox

Continuation for all vehicles

|

|

|

Note: Assembly mounting tightening torques .

Vehicles with air conditioner

Continuation for all vehicles

=> Electrical system; Repair group 97

Vehicles with manual gearbox

=> Repair group 30; Servicing hydraulic clutch control

=> Repair group 34; Servicing gear change mechanism Vehicles with automatic gearbox

=> Repair group 37; Servicing selector mechanism; Dismantling and assembling selector mechanism Continuation for all vehicles

=> Repair group 24; Servicing injection system; Dismantling and assembling air cleaner.

=> Repair group 24; Engine control unit; Procedure after interrupting voltage supply. Note: The readiness code is reset or erased each time fault memory is erased.

=> Repair group 01; Fault memory; Interrogating and erasing fault memory of engine control unit |