Polo Mk3

|

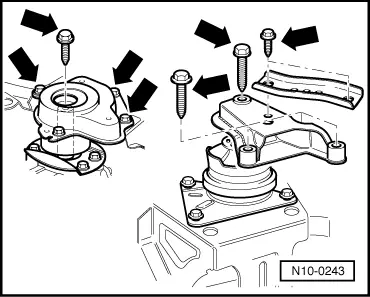

Removing and installing engine

Notes on removing

Note: Check whether a coded radio is installed as during the forthcoming work sequences the battery earth strap must be disconnected. Obtain radio code first if necessary.

=> Repair group 24; Servicing injection; Dismantling and assembling air cleaner

Warning!

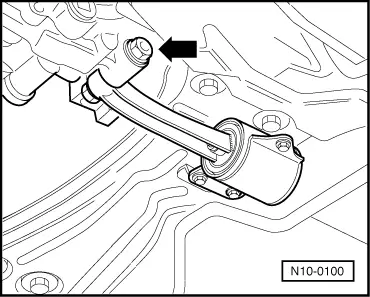

Fuel supply lines are under pressure! Before removing from hose connection wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection.

|

|

|

Vehicles with manual gearbox

=> Repair group 30; Servicing hydraulic clutch control

=> Repair group 34; Servicing gear change mechanism Vehicles with automatic gearbox

=> Repair group 37; Servicing selector mechanism; Dismantling and assembling selector mechanism Continuation for all vehicles

Vehicles with air conditioner

Continuation for all vehicles

=> General body repairs exterior; Repair group 50; Body front; Assembly overview |

|

|

|

Vehicles with manual gearbox

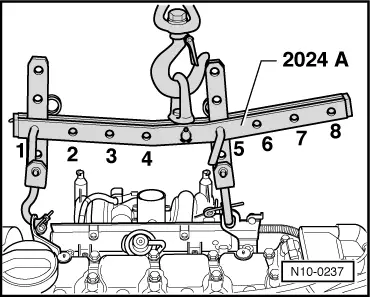

Pulley end:

Flywheel end: Warning!

The hooks and locating pins must be secured with locking pins. Notes:

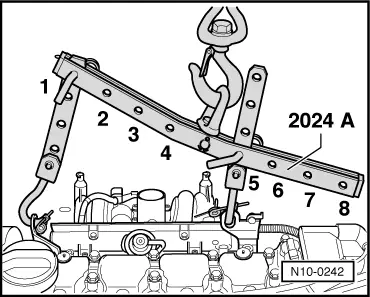

Vehicles with automatic gearbox |

|

|

Flywheel end: Warning!

The hooks and locating pins must be secured with locking pins. Notes: |

|

|

Vehicles with manual gearbox

|

|

|

|

Vehicles with automatic gearbox

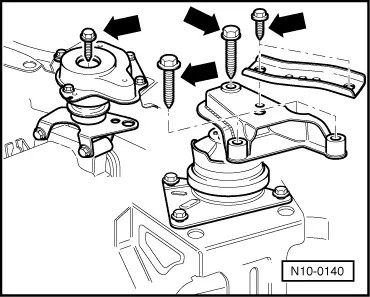

Continuation for all vehicles

Note: When the assembly is lifted off, it must be carefully guided to prevent damage to the bodywork. |