|

→

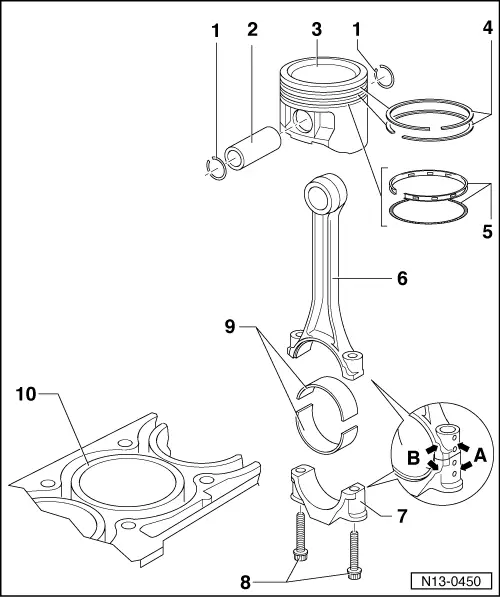

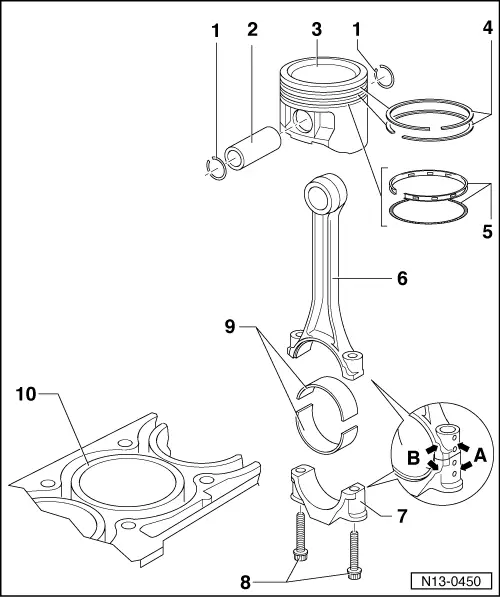

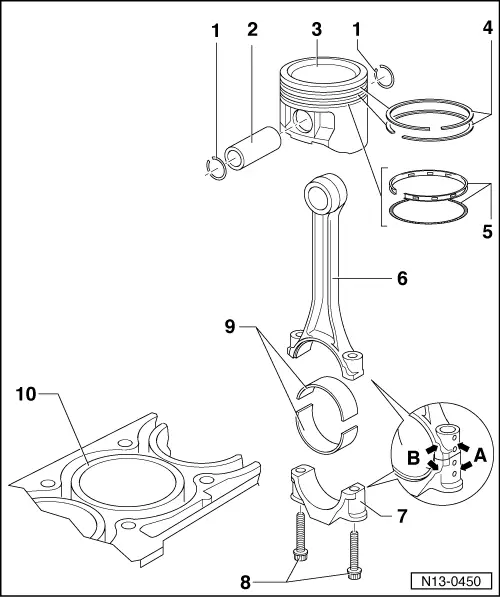

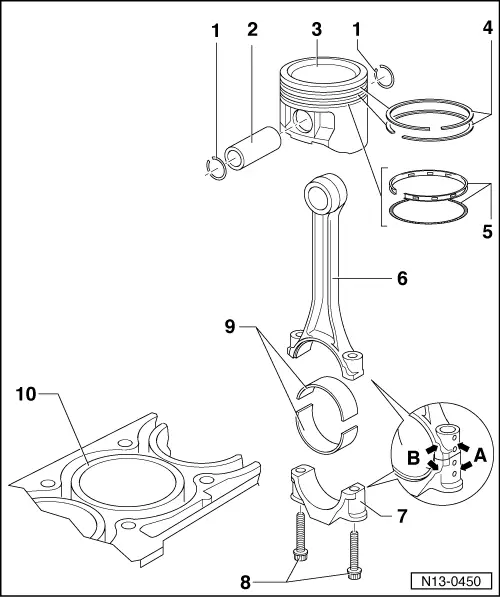

Fig. 4

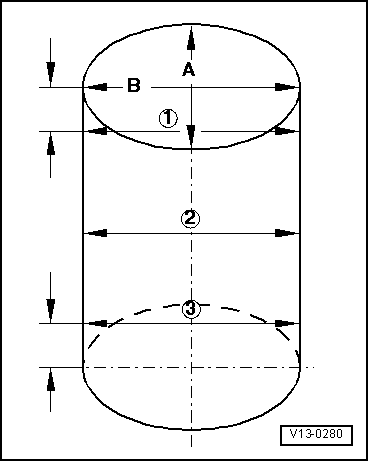

Checking cylinder bores

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

-

◆ Internal dial gauge 50...100 mm

-

‒ Take measurements at 3 positions in both lateral -A- and longitudinal -B- directions, as illustrated. Deviation from nominal dimension

max. 0.08 mm

- Nominal dimension => Page 13-50

; Piston and cylinder dimensions

Note:

Measuring the cylinder bores must not be done when the cylinder block is mounted on a repair stand with adapter bracket VW 540, as incorrect measurements would then be possible.

|