Polo Mk3

|

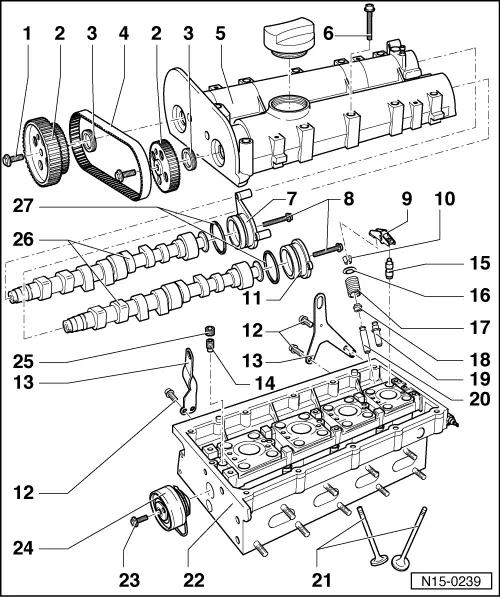

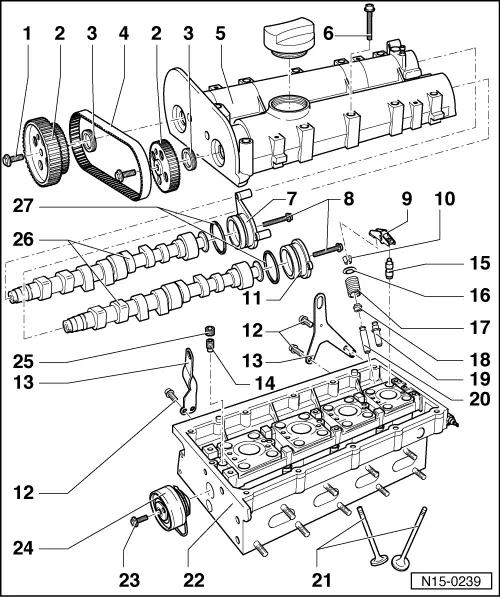

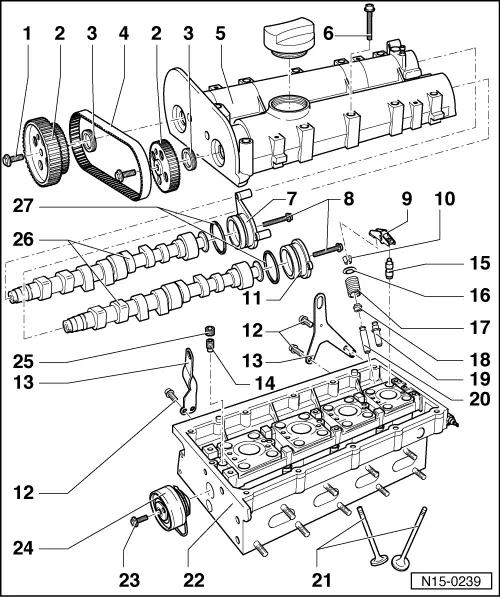

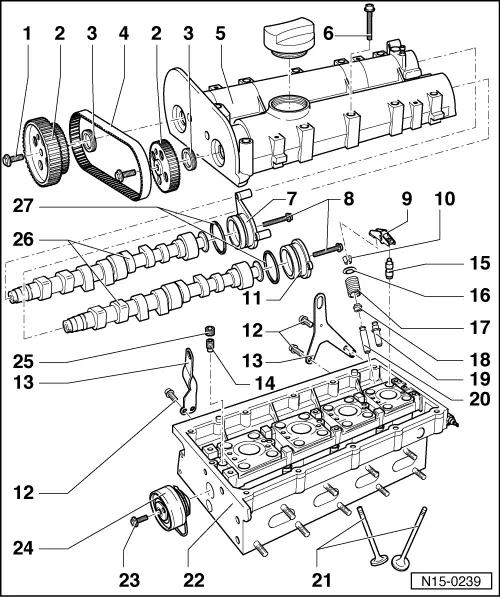

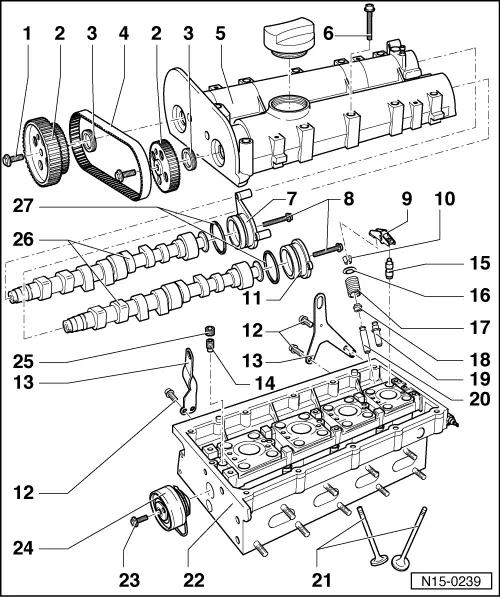

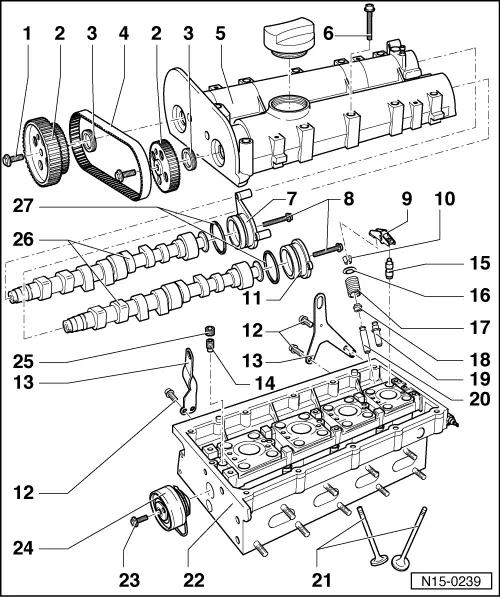

Servicing valve gear

Servicing valve gear

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

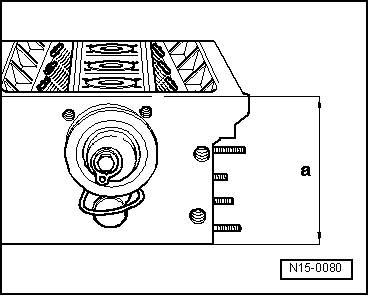

→ Fig. 2 Reworking cylinder head sealing surface Cylinder head reworking dimension: |

|

|||||||||||||||||||||

|

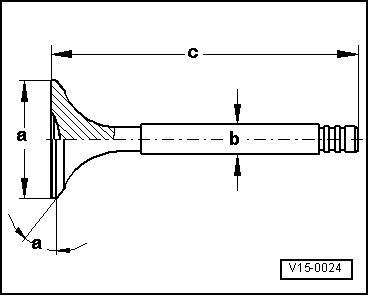

→ Fig. 5 Valve dimensions Note: Valves must not be reworked. Only lapping-in is permitted.

| |||||||||||||||||||||