-

‒ →

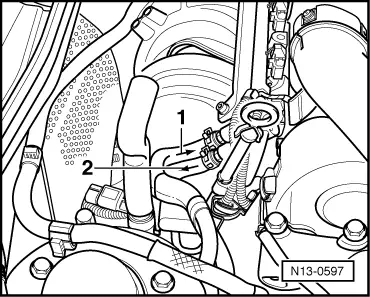

Disconnect fuel supply and fuel return pipes at fuel rail, items -1- and -2-.

Warning!

Fuel supply lines are under pressure! Before removing from hose connection wrap a cloth around the connection. Then release pressure by carefully pulling hose off connection.

-

‒ Seal the pipes so that the fuel system is not contaminated by dirt etc.

-

‒ Observe rules for cleanliness

.

-

‒ Disconnect clutch cable:

=> 5-speed manual gearbox 085; Repair group 30; Servicing clutch mechanism

-

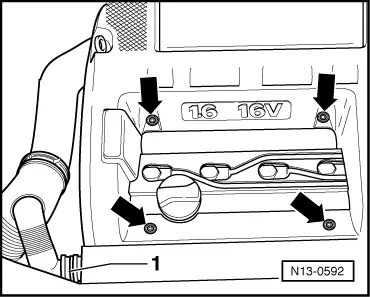

‒ Remove connecting hose for air cleaner/air intake connecting piece.

-

‒ Open and close the expansion tank sealing cap to release pressure in cooling system.

-

‒ Loosen or separate the following components:

-

‒ The hose from activated charcoal filter system to throttle valve control part

-

‒ The vacuum hose from brake servo to inlet manifold

-

‒ The collective connectors below thermostat housing

-

‒ The connector from engine speed sender below oil dipstick tube bracket, and pull connector out from retainer

-

‒ The connector from ignition transformer, from Hall sender and throttle valve control part

-

‒ The connector from coolant temperature sender, oil pressure switch and the engine oil temperature switch

-

‒ Remove noise insulation tray:

=> General body repairs; Repair group 50; Front body; Removing insulation tray

-

‒ Loosen or separate the following components:

-

‒ Connector for Lambda probes

-

‒ Drain coolant => Page 19-11

.

-

‒ Pull off coolant hose at engine with assembly tool for spring-type clamps VAS 5024.

-

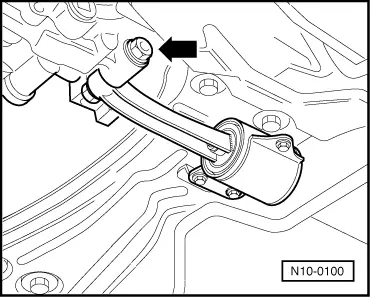

‒ Loosen belt pulley securing bolts from power steering vane pump.

-

‒ Remove ribbed belt => Page 13-12

.

-

‒ Unbolt power steering vane pump and secure to sub-frame with wire; hoses remain connected:

=> Running gear; Repair group 48; Assembly overview: vane pump, reservoir, hydraulic lines; Removing and installing power steering vane pump.

-

‒ Remove left and right-hand drive shaft on gearbox and tie up:

=> Running gear, Axles, Steering; Repair group 40; Servicing front suspension; Removing and installing drive shafts

Vehicles with air conditioner

-

‒ Removing air conditioner compressor:

-

‒ Observe additional information and removal instructions =>Page10-15

|