Polo Mk3

|

Servicing valve gear

Removing and installing camshaft adjuster and exhaust camshaft sprocket

|

|

|

|

|

|

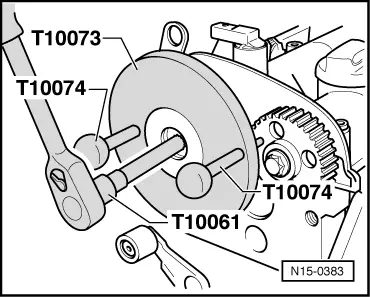

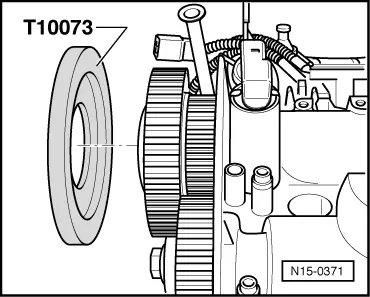

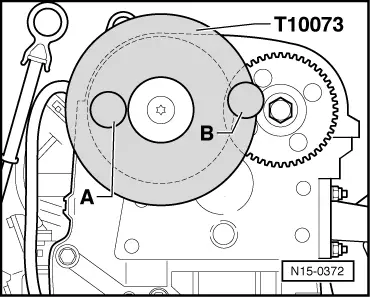

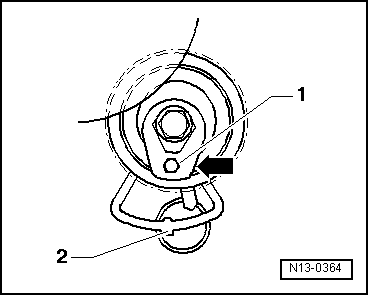

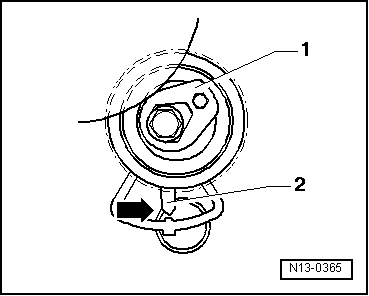

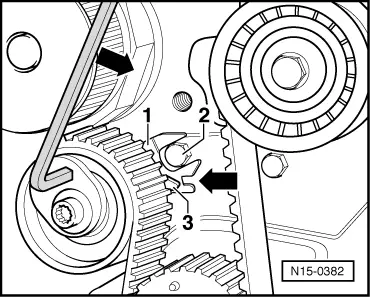

Note: Turning the exhaust camshaft sprocket slightly with a ring spanner on the securing bolt until the fitted holes align will make locking easier.

|

|

|

Note: The camshaft adjuster central bolt has a left-hand thread.

Note: The hexagon bolt securing the exhaust camshaft sprocket has a right-hand thread and must be replaced.

Installing

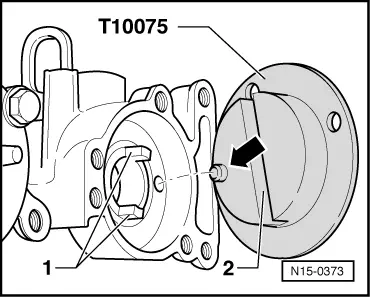

Note: Observe position of camshaft sprocket to camshaft keyway. |

|

|

Note: When replacing the camshaft adjuster, the oil seal must also be replaced. Ensure that the oil seal is not damaged when guiding the camshaft adjuster in the camshaft housing.

Note: The camshaft adjuster must turn easily compared to the camshaft. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: The locking will be made easier when the exhaust camshaft sprocket is turned slightly with a ring spanner on the securing bolt, until the fitted holes align.

|

|

|

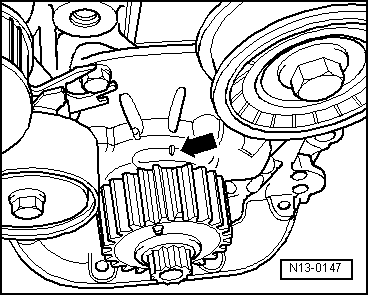

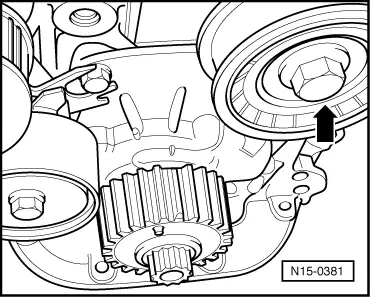

Install both toothed belts as follows: Note: If a piston is at TDC the valves could strike the piston when turning the camshafts.

|

|

|

|

|

|

Note: The camshafts must remain secured against turning until the main dive toothed belt has been fitted. |

|

|

|

|

|

|

|

|

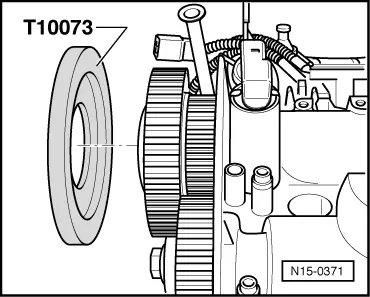

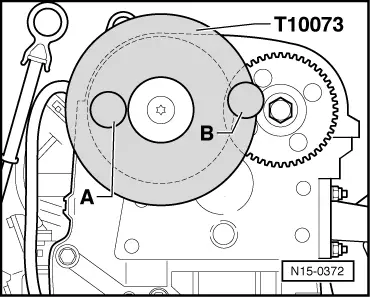

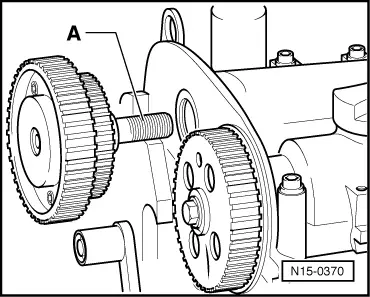

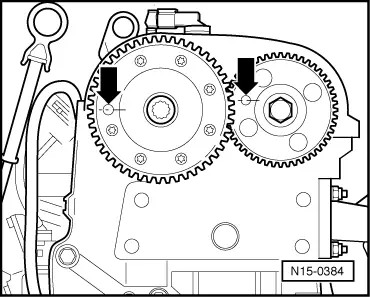

The holes in camshaft adjuster and exhaust camshaft sprocket must align with the fitted holes in camshaft housing. |

|

|

|

|

|

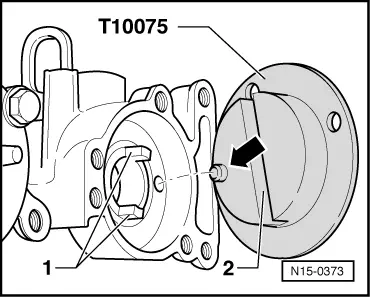

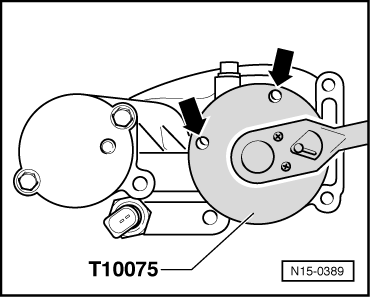

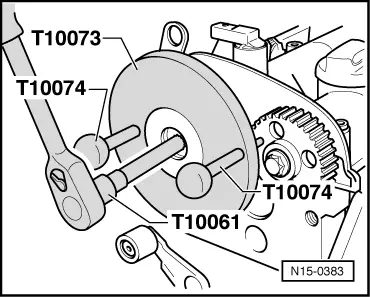

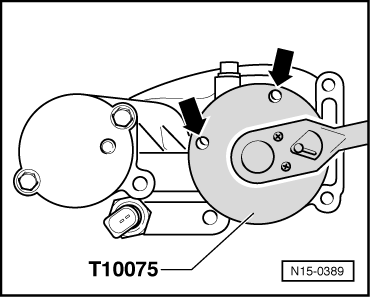

The tool must now move to the position which was attained during the adjustment process, i.e. the holes in locking flange T10075 must align with the threaded holes in the camshaft housing -arrows-. Note: If the original position of the locking and adjustment tool is not attained, both toothed belts must be removed, the camshaft adjuster must be loosened and the process repeated.

The rest of the assembly is basically a reverse of the dismantling sequence. |