Polo Mk3

|

Dismantling and assembling cylinder block, crankshaft and flywheel

Renewing crankshaft sealing flange -flywheel end-

|

|

|

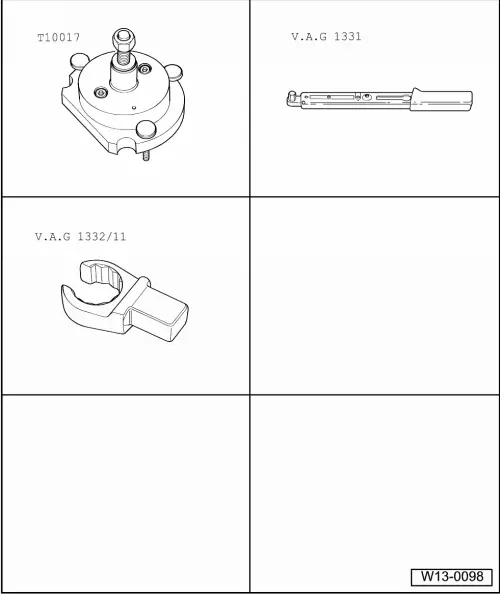

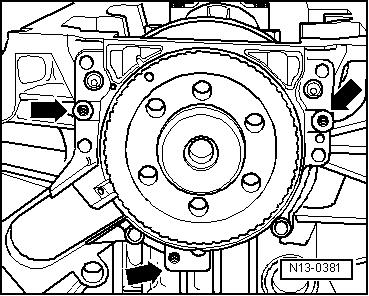

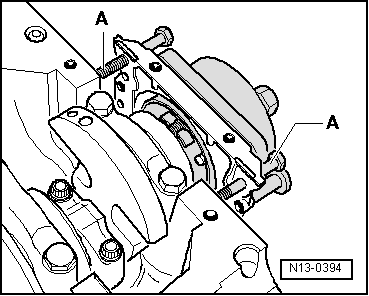

Note: Sealing flange and sender wheel are pressed off the crankshaft together with Qty. 3 M6 x 35 mm bolts. |

|

|

Pressing in sealing flange with sender wheel Notes:

|

|

|

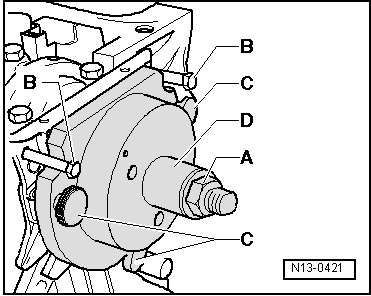

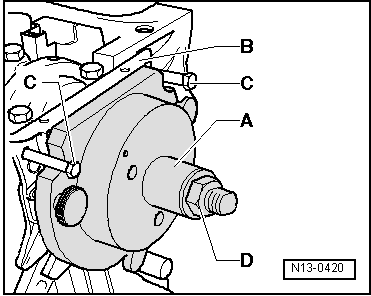

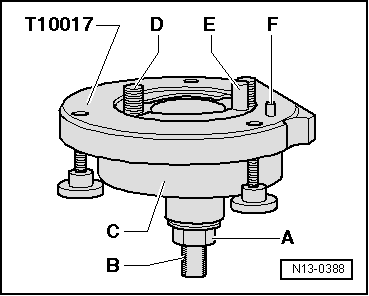

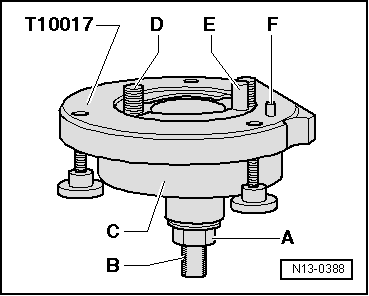

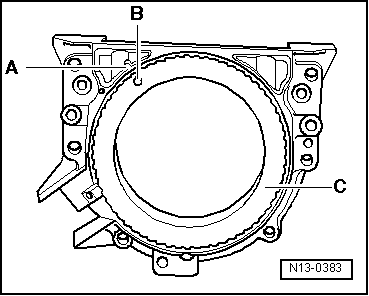

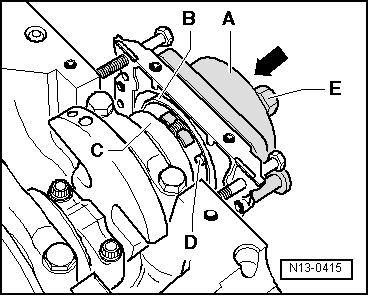

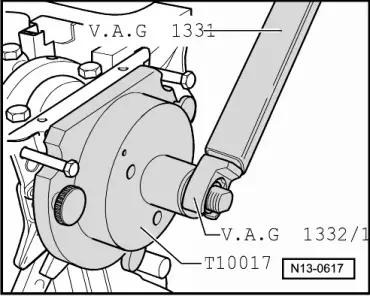

→ A - Hexagon nut B - Clamping surface (ground section of spindle) C - Tool bell housing D - Socket head bolt E - Guide pin |

|

|

|

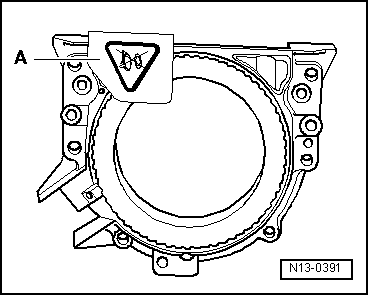

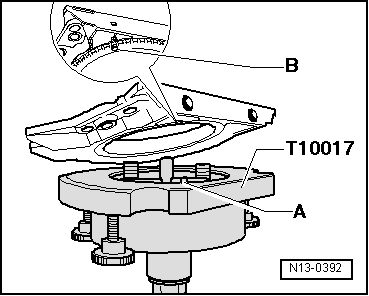

F - Locating pin A-Assembling sealing flange with sender wheel on assembly appliance T10017

|

|

|

Note: Inner part of assembly appliance and assembly bell housing must be at same height (level). |

|

|

Note: The sender wheel must not be taken out of the sealing flange or twisted. |

|

|

|

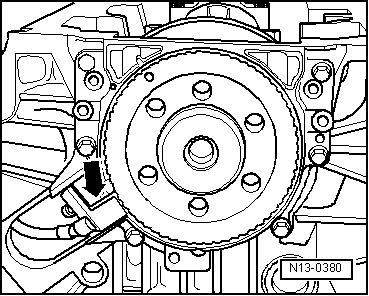

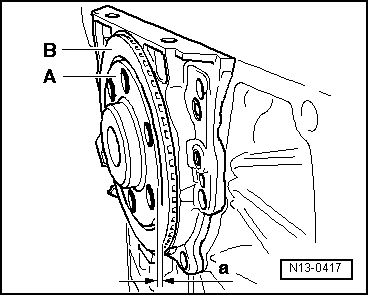

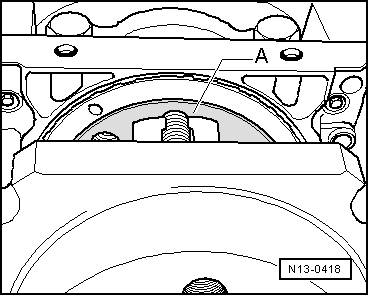

→ The locating hole -B- on the sender wheel -C- must align with the marking -A- on the sealing flange. |

|

|

|

|

|

|

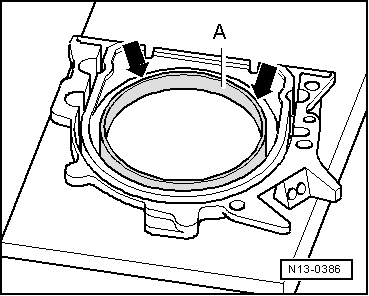

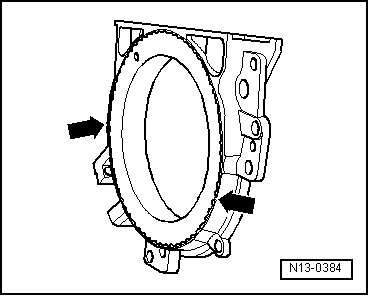

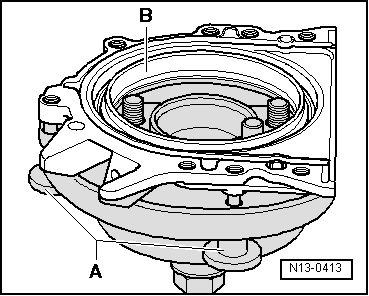

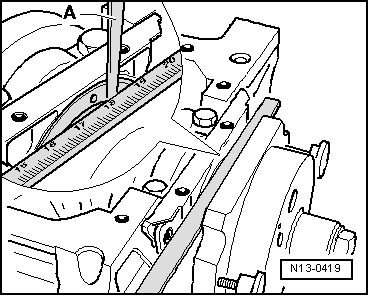

→ The upper edge of the sender wheel and the forward edge of the sealing flange must align -arrows-. |

|

|

Note: Ensure the sealing flange lies flat on the assembly appliance. |

|

|

Note: Ensure the sender wheel remains fixed on the assembly appliance when installing the sealing flange. B-Assembling appliance T10017 with sealing flange on crankshaft flange Prerequisites |

|

|

Work sequence

|

|

|

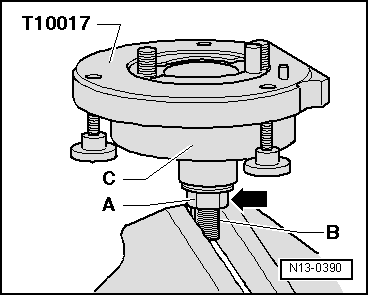

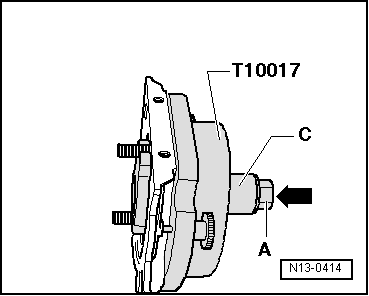

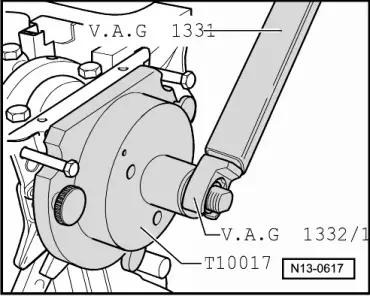

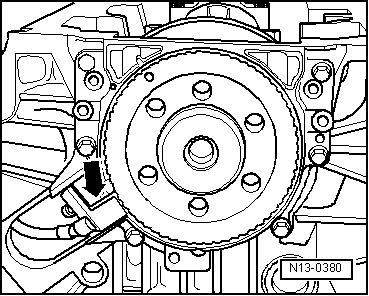

Note: Screw hexagon socket head bolts -A- into crankshaft flange (approx. 5 threads). |

|

|

C-Fitting assembly appliance T10017 onto crankshaft flange |

|

|

Note: The assembly appliance guide pin -D- is guided into threaded hole in crankshaft during the fitting sequence. This ensures the sender wheel reaches its final installation position.

|

|

|

|

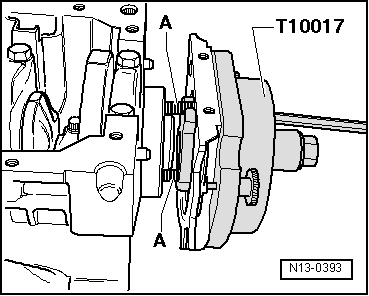

D-Pressing sender wheel onto crankshaft flange with assembly appliance T10017

Note: A small air gap must be present between cylinder block and sealing flange after tightening hexagon nut to 35 Nm. |

|

|

|

→

The sender wheel has the correct installation position on crankshaft when a gap of Note: If the sealing flange has a PTFE sealing ring, completely unbolt the assembly appliance T10017 and remove the sealing lip support ring. To enable the measurements to be shown more clearly the crankshaft flange is illustrated without the fitted assembly appliance T10017. |

|

|

|

|

|

Is measurement -a- too small:

When dimension -a- is achieved:

|

|

|

|

|

|

If dimension -a- is too small again:

|