|

Removing and installing parts of the lubrication system

Removing and installing oil sump

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

-

◆ Socket 3249

-

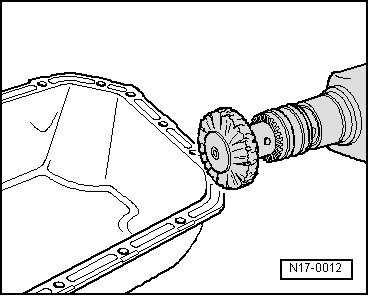

◆ Hand drill with plastic brush

-

◆ Flat scraper

-

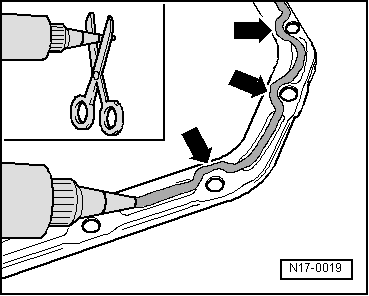

◆ Silicone sealant D176404 A2

-

◆ Torque wrench V.A.G 1331 (5...50 Nm)

Work sequence

-

‒ Drain engine oil.

-

‒ Remove ribbed belt guard and the cable guide from the sump.

-

‒ Remove front exhaust pipe from exhaust manifold.

-

‒ Unbolt right-hand drive shaft at gearbox.

=> Running gear; Repair group 40; Servicing front suspension; Removing and installing wheel bearing, suspension strut and drive shaft

-

‒ Remove cover plate for flywheel.

-

‒ Unbolt sump sealed with liquid gasket.

-

‒ Remove sump, it may be necessary to release sump by tapping lightly with a rubber head hammer.

-

‒ Remove sealant residue on cylinder block with a flat scraper.

|