Polo Mk3

|

Dismantling and assembling cylinder block, crankshaft and flywheel

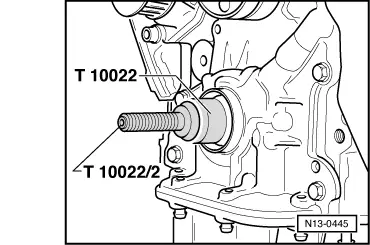

Renewing crankshaft oil seal - pulley end -

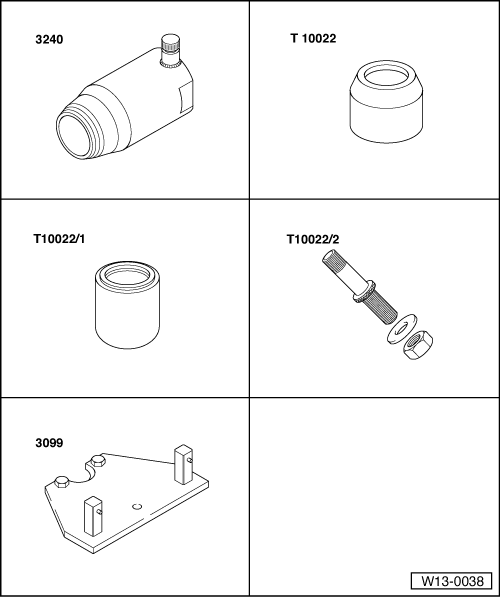

Vehicles with oil pump driven by chain and vehicles with Duo-centric oil pump Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

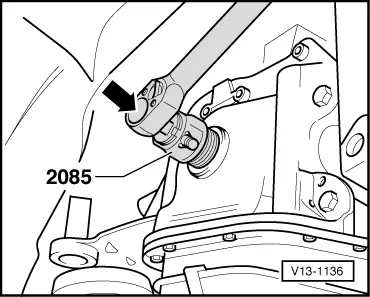

Removing

|

|

|

Installing

|

|

|

|

|

|

|

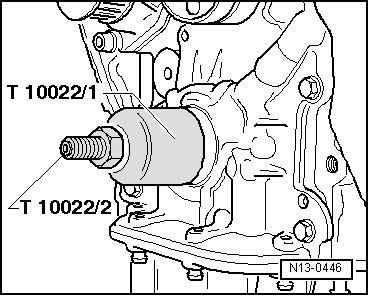

Vehicles with Duo-centric oil pump Special tools, workshop equipment, test and measuring appliances and aux. items required

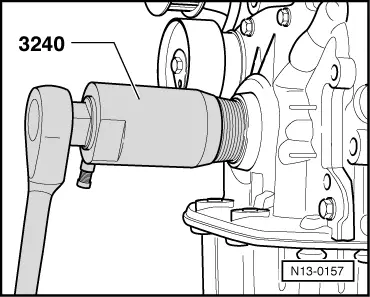

Removing

|

|

|

|

|

|

|

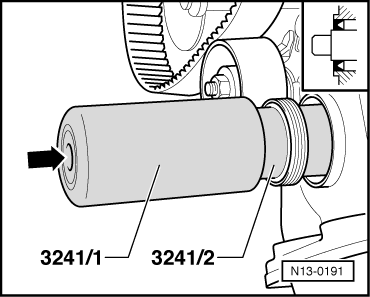

Installing

|

|

|

|