Polo Mk3

|

Dismantling and assembling engine

Removing and installing toothed belt

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

Removing

=> Repair group 24; Servicing injection; Dismantling and assembling air cleaner |

|

|

|

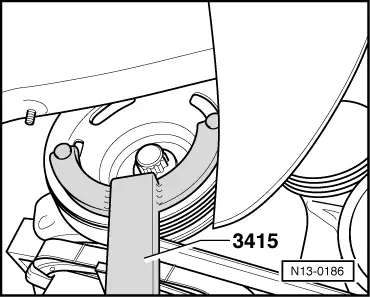

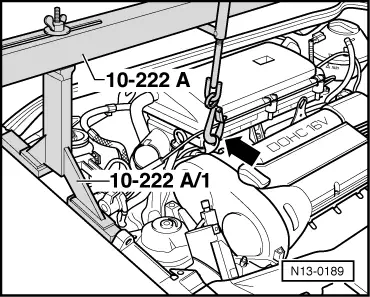

The engine must be lowered slightly as follows to enable the crankshaft sprocket to be removed:

|

|

|

|

|

|

|

|

|

|

|

|

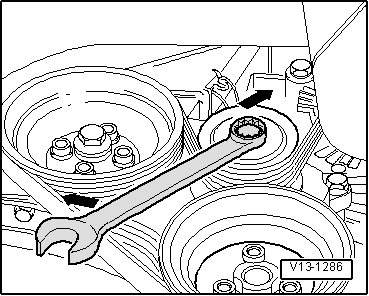

Note: When installing the ribbed belt ensure that it sits correctly in the pulleys.

=> Repair group 28; Injection and ignition system; Checking and adjusting ignition timing. |