Polo Mk3

|

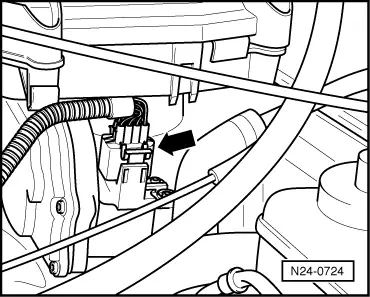

Checking components

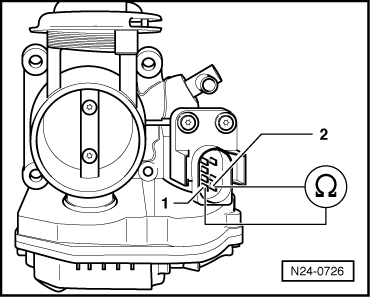

Checking throttle valve control part

Components of the throttle valve control part (J338): Note: If the throttle valve control part is replaced, the following must be carried out:

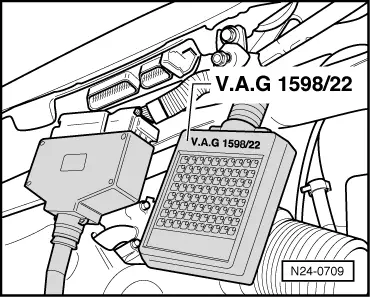

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

Checking idling switch Test sequence

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

|

→

Indicated on display: (1...4 = Display zones) |

|

|||||||||

Display constantly remains on one operating condition:

|

|

|

|

Continuation of check when display constantly shows part throttle

|

|

|

If display jumps to idling:

If display remains on idling:

If the voltage supply and wiring is OK:

Continuation of check when display constantly shows idling |

|

|

If display jumps to part throttle:

If display remains on part throttle:

If the voltage supply and wiring is OK:

Checking throttle valve positioner and throttle valve positioner potentiometer Test conditions

Test sequence

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| →

Indicated on display: (1...4 = Display zones) |

|

||

|

| → Indicated on display: |

|

||

|

|

→

Indicated on display: (1...4 = Display zones) |

|

||

If the specification is not obtained:

|

|

|

|

|

|

If the specification is not obtained:

If the specification is attained:

Checking throttle valve potentiometer Test conditions

Test sequence

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| →

Indicated on display: (1...4 = Display zones) |

|

||

|

| →

Indicated on display: (1...4 = Display zones) |

|

|||||||||

Note: The displayed figure is dependent on the tolerances of the throttle valve potentiometer and does not correspond to the actual opening angle. If the figure does not increase uniformly:

If the display constantly shows 0 <° or is above 90 <°:

|

|

|

|

Continuation of check when display shows 0 <°:

|

|

|

If display jumps above 90 <°:

If display remains at 0 <°:

If the voltage supply and wiring is OK:

Continuation of check when display is above 90 <°: |

|

|

If display jumps to 0 <°:

If display remains above 90 <°:

If the voltage supply and wiring is OK:

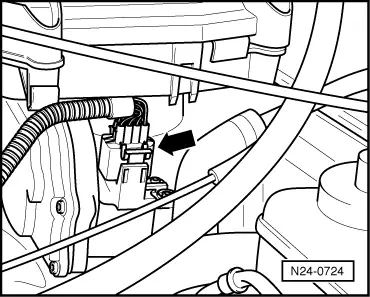

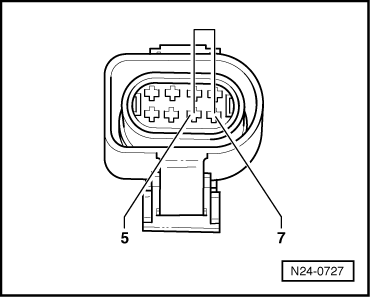

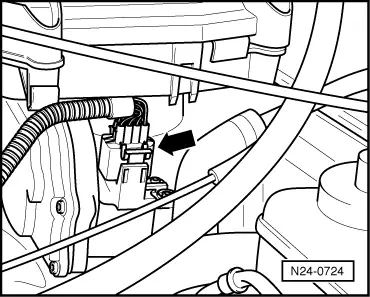

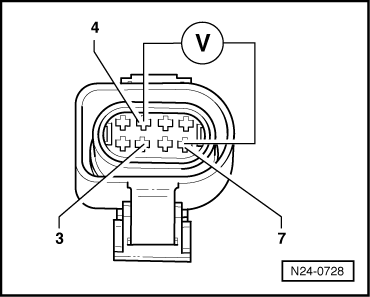

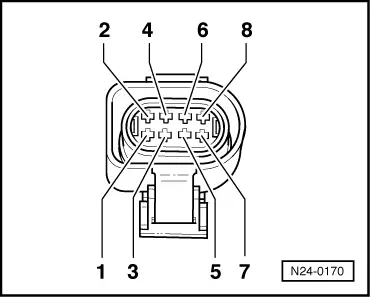

Checking voltage supply and wiring to control unit Test conditions

|

|

|

|

Test sequence

|

|

|

|

|

|

|

|

|

If no wiring fault is detected:

|