Polo Mk3

|

|

|

Check conditions

|

|

|

|

Test sequence

|

|

|

|

|

|

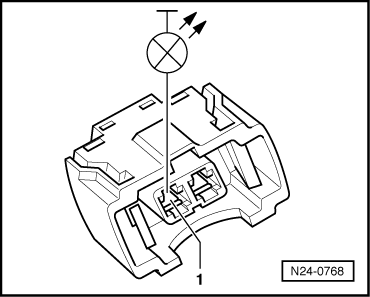

If the LED does not light up on any cylinder: |

|

|

If the LED does not light up:

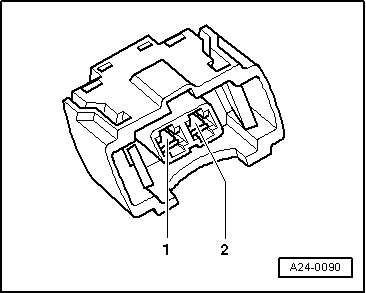

If the LED does not light up on one or several cylinders: |

|

|

|

|

|

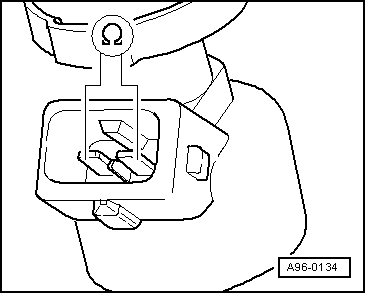

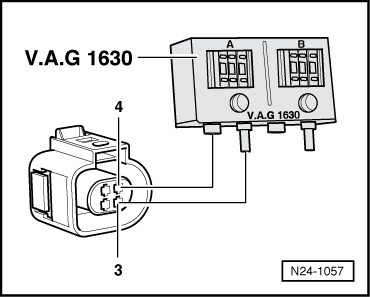

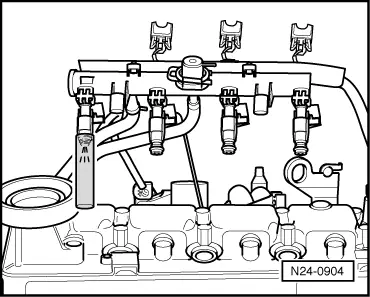

Checking resistance of injectors Test sequence |

|

|

Note: The resistance figures are valid for approx. 20 °C. At higher temperatures the resistance figures will increase. If the specification is not attained: Perform installation of injectors in reverse order. When doing this note the following:

|

|

|

|

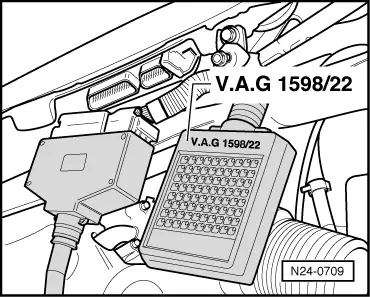

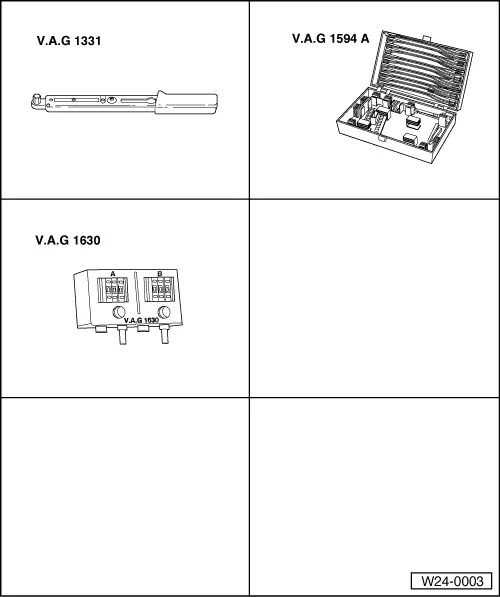

Checking spray pattern and for leaks Special tools, workshop equipment, test and measuring appliances and auxiliary items required

Test conditions

|

|

|

|

Test sequence |

|

|

|

|

|

|

|

|

|

|

If the fuel loss is greater: Perform installation of injectors in reverse order. When doing this note the following:

|