Polo Mk3

|

Servicing front suspension

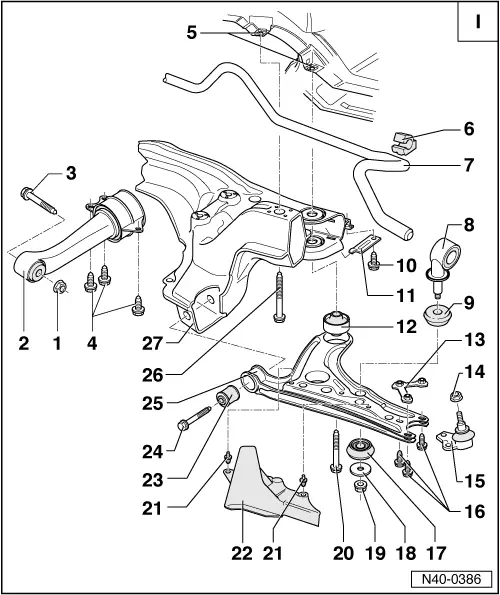

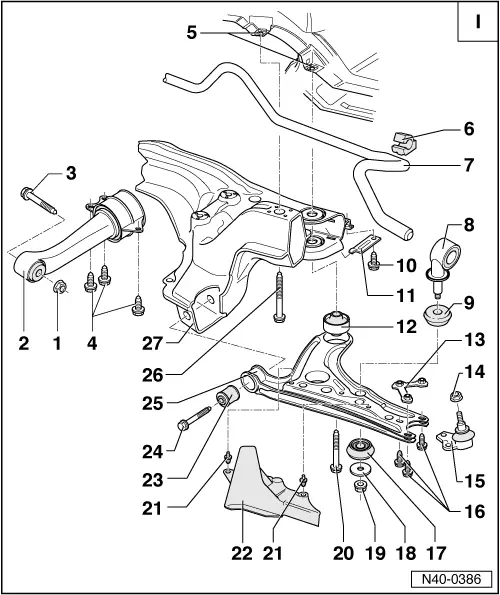

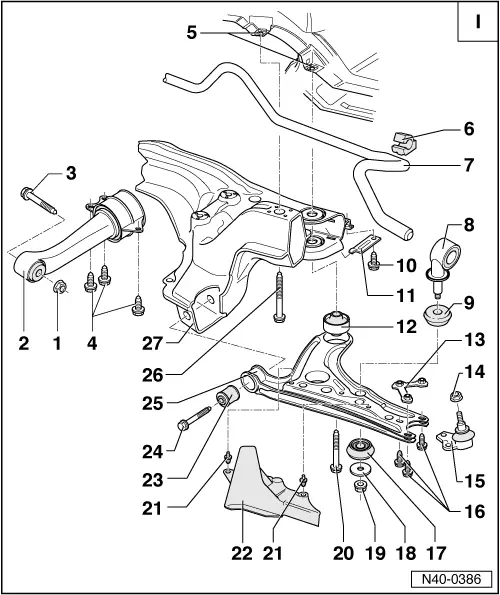

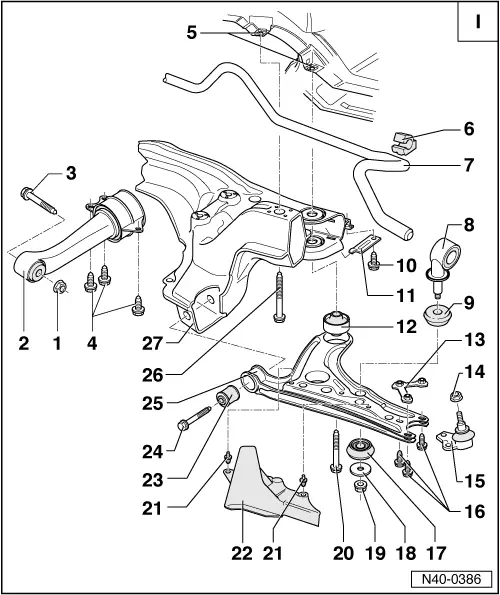

I - Assembly overview sub-frame, anti-roll bar, wishbone

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

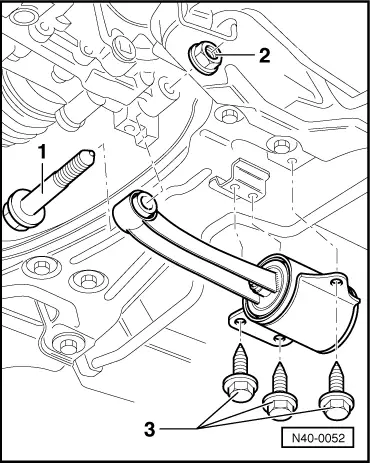

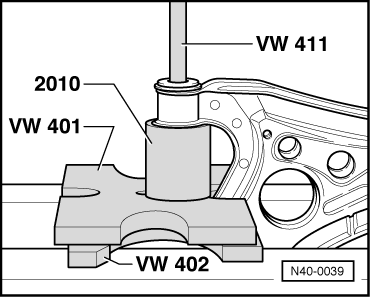

→ Fig.1 Pressing out front wishbone mounting |

|

|

|

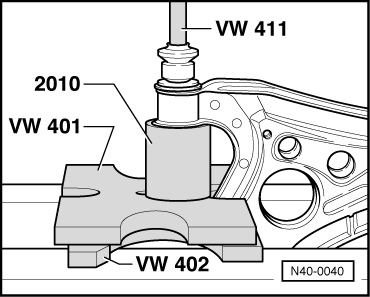

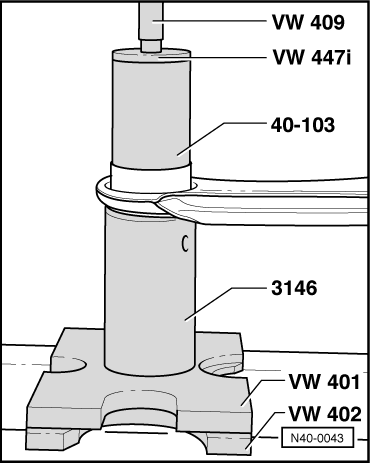

→ Fig.2 Pressing in wishbone front mounting Note: Before pressing in coat with acid-free lubricant e.g. soft soap or tyre assembly paste. |

|

|

|

→ Fig.3 Pressing wishbone rear bush out |

|

|

|

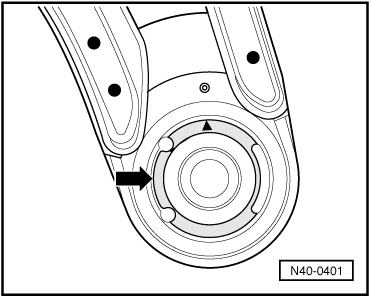

→ Fig.4 Installation position of rear wishbone mounting One of the embossed arrows points towards the mark on wishbone. The section of the mounting -arrow- must always point to outside of vehicle. |

|

|

|

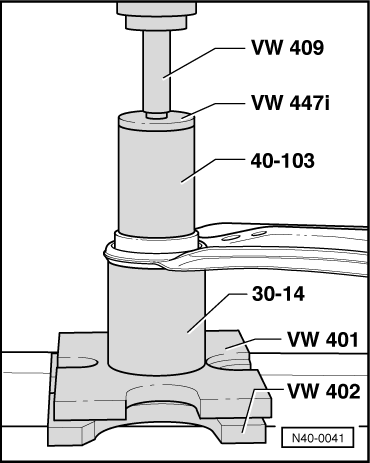

→ Fig.5 Pressing wishbone rear bush in |