Polo Mk4

| Differential - dismantle and assemble |

| Special tools and workshop equipment required |

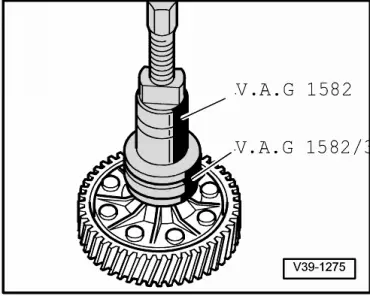

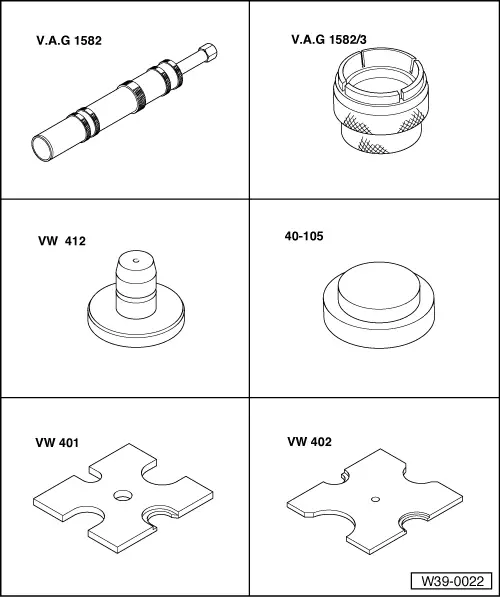

| t | Puller -VAG 1582- |

| t | Clamp -VAG 1582/3- |

| t | Pressure disc -VW 412- |

| t | Installation disc -40-105- |

| t | Plate -VW 401- |

| t | Plate -VW 402- |

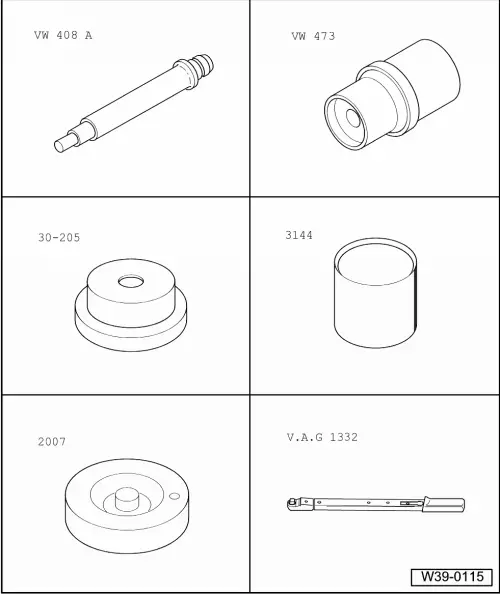

| t | Pressure pin -VW 408A- |

| t | Placer -VW 473- |

| t | Pressure base -30-205- |

| t | Sleeve -3144- |

| t | Disc -2007- |

| t | 40- 200 Nm Torquemeter -VAG 1332- |

Note

Note

|

|

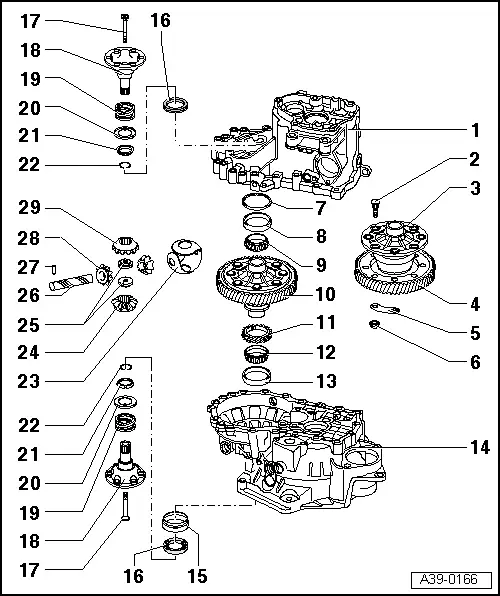

| 1 - | Gearbox housing |

| 2 - | Screw |

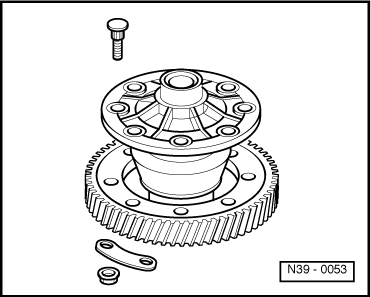

| 3 - | Differential case |

| q | Bolt to final drive gear. |

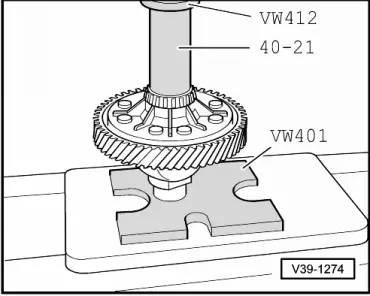

| 4 - | Final drive gear |

| q | Rivetted in production. |

| q | Is paired with output shaft, only renew as a set. |

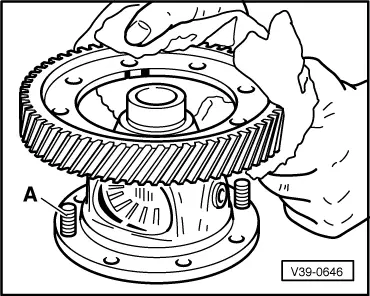

| q | Remove → Fig. |

| q | Installation position → Fig. |

| q | Heat to 212°F, before installation. |

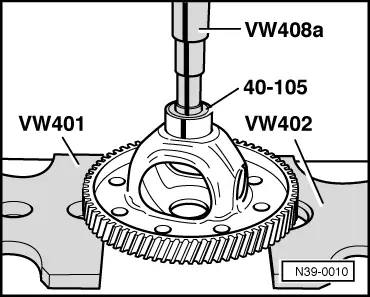

| q | Fit to differential housing → Fig. |

| q | Secure → Fig. |

| 5 - | Backing plate |

| 6 - | Nut; 70 Nm |

| 7 - | Adjustment shim |

| q | For differential. |

| q | Check thickness → Chapter |

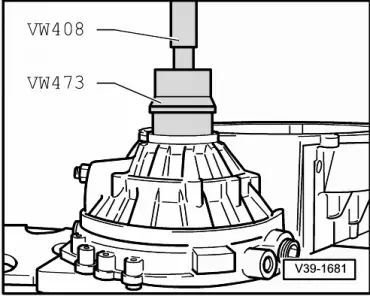

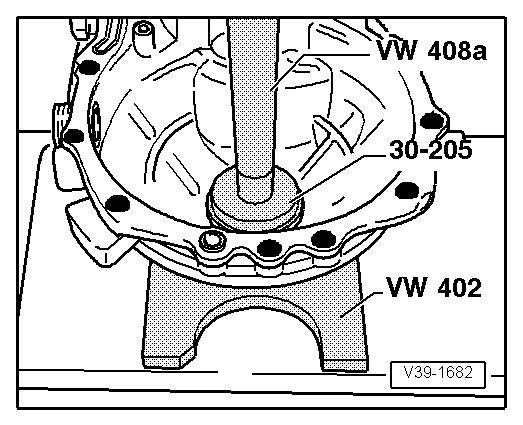

| 8 - | Outer race/taper roller bearing |

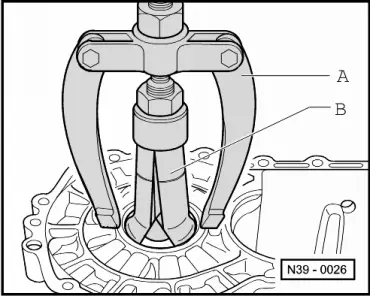

| q | Remove → Fig. |

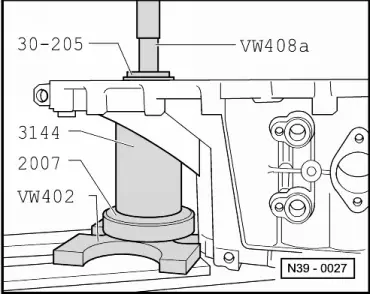

| q | Install → Fig. |

| 9 - | Taper roller bearing inner race |

| q | Remove → Fig. |

| q | Install → Fig. |

| 10 - | Differential housing |

| q | With rivetted final drive gear. |

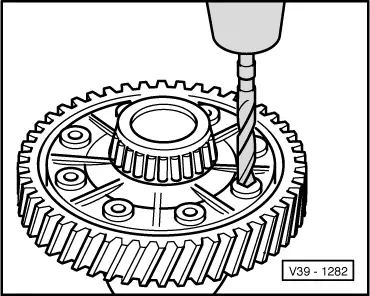

| q | When renewing final drive gear drill out rivet heads → Fig. |

| q | Attach final drive gear with bolts → Fig. |

| 11 - | Speedometer drive wheel |

| q | Fit onto differential housing as far as stop before pressing on inner race. |

| 12 - | Taper roller bearing inner race |

| q | Remove → Fig. |

| q | Install → Fig. |

| 13 - | Outer race/taper roller bearing |

| q | Remove → Fig. |

| q | Install → Fig. |

| 14 - | Clutch housing |

| 15 - | Bushing |

| q | To accept oil seal ( → Item) |

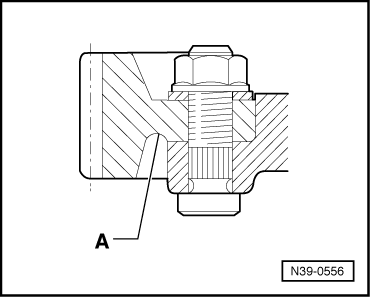

| q | Remove and install → Fig. |

| 16 - | Seal |

| q | Renew with gearbox installed → Chapter. |

| 17 - | Countersunk head bolt, 25 Nm |

| q | Bolt into threaded piece ( → Item). |

| 18 - | Flange shaft |

| q | Remove and install → Chapter. |

| 19 - | Spring for flanged shaft |

| q | Installed behind flanged shafts. |

| 20 - | Thrust washer |

| q | Installation position: Shoulder towards spring, tongue to tapered ring. |

| 21 - | Tapered ring |

| q | With grooves to secure thrust washer. |

| q | Installation position: Taper towards differential housing. |

| 22 - | Circlip |

| q | Ensures that taper ring, thrust washer and spring are held in position when flange shaft is removed. |

| 23 - | One-piece thrust washer |

| q | Install with gearbox oil. |

| 24 - | Sun wheel |

| q | Install → Fig. |

| 25 - | Threaded piece |

| q | Install → Fig. |

| 26 - | Planet pinion axis shaft |

| q | Knock out with drift. |

| q | Install → Fig. |

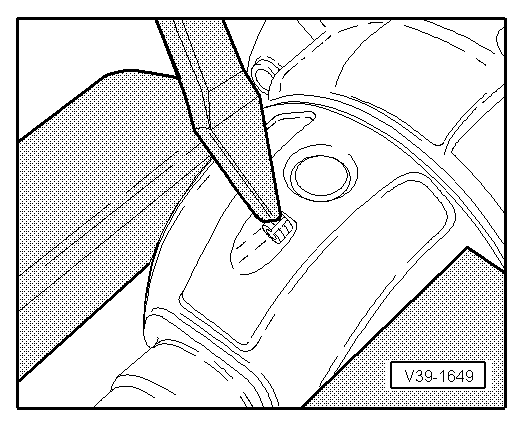

| 27 - | Spring pin |

| q | For securing planet pinion axis shaft. |

| q | Remove and install → Fig. |

| 28 - | Planet pinion |

| q | Install → Fig. |

| 29 - | Sun wheel |

| q | Install → Fig. |

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|