Polo Mk4

|

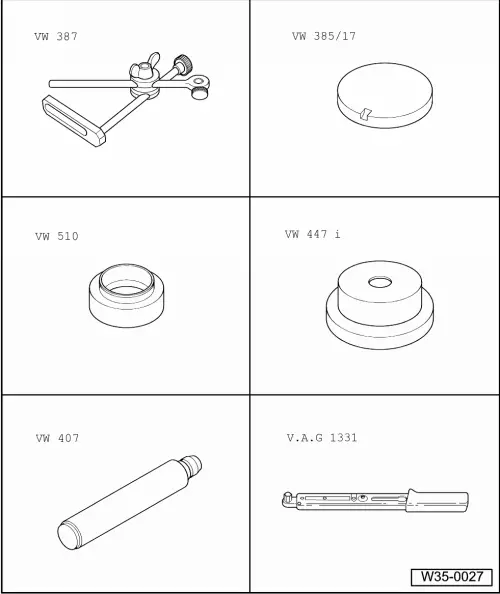

| Special tools and workshop equipment required |

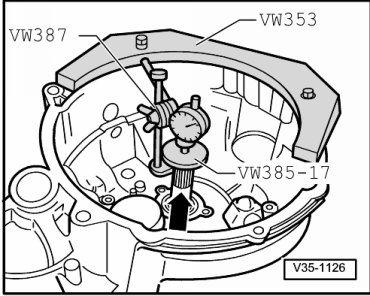

| t | Clock mounting -VW 387- |

| t | Final measurement plate -VW 385/17- |

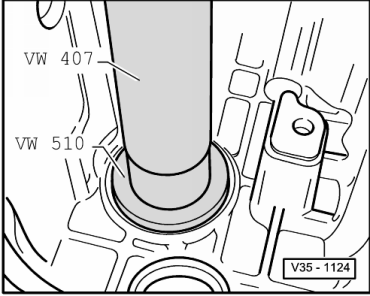

| t | Pressure disc -VW 510- |

| t | Pressure disc -VW 447 i- |

| t | Pressure pin -VW 407- |

| t | 5 - 50 Nm Torquemeter -VAG 1331- |

| t | Dial gauge |

|

|

|

Note

Note

|

|

Note

Note

|

|