| Pressing sealing flange with sender wheel onto crankshaft |

Note | t

| Gradual introduction of a new generation of sealing flanges with PTFE seal (Teflon). The sealing flange with spring ring will continue to be offered as spare part. When fitting a new sealing flange, be careful to use the same type of sealing flange that was previously fitted. |

| t

| The sealing flange with a PTFE seal is equipped with a sealing lip support ring. This support ring serves as a fitting sleeve and must not be removed prior to installation. |

| t

| Sealing flange and sender wheel must not be separated or turned after removal from packaging. |

| t

| The sender wheel of a sealing flange with spring ring has an elastomer coating on the sealing surface to crankshaft. This coating must never come into contact with dirt or grease. |

| t

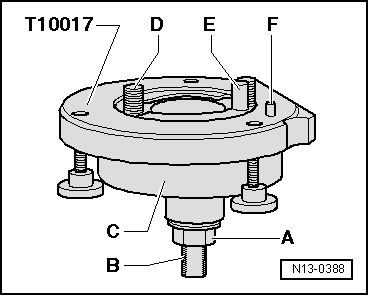

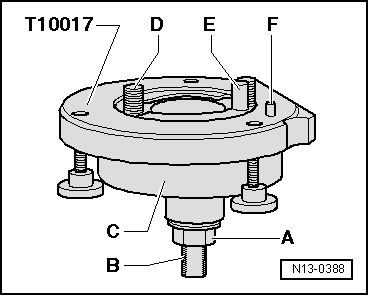

| The sender wheel is held in its installation position by a fixture on the assembly device -T10017- locating pin. |

| t

| Sealing flange and seal are one unit and must be replaced together with the sender wheel only. |

| t

| Assembly appliance -T10017- maintains its installation position relative to crankshaft via a guide pin which is inserted into a threaded hole in crankshaft. |

|

|

|

Note

Note

Note

Note